UV printer software is constantly changing and evolving — as are the needs of your business. Software is the backbone of your printer, controlling many of the functions utilized in the printing process. Because your printer’s software is so vital, you need to ensure that it allows for innovations in technology, maximizes functionality, and enhances workflow. This will lead to increased efficiency and production, which in turn increases the profitability of your business.

Following are some of the most important functions that software should provide to maximize the efficiency of your UV printer:

Extend the capabilities of the printer

The software should:

- Work with most third-party graphics programs, combining the channel data with the software. This allows for advanced printing techniques such as layering for textures and 3D effects.

- Produce consistent spot colors by using metadata linking a color value to a name tag. This named color space (NCS) allows designers to easily reproduce exact colors.

- Print small, fine details on small diameter objects through advanced head control.

Provide enhanced color management

Your printer should enable operators to use varying media profiles to control the ink volumes more granularly, especially when using a white underbase. This reduces the amount of white underbase required and provides substantial ink savings without compromising the final color output.

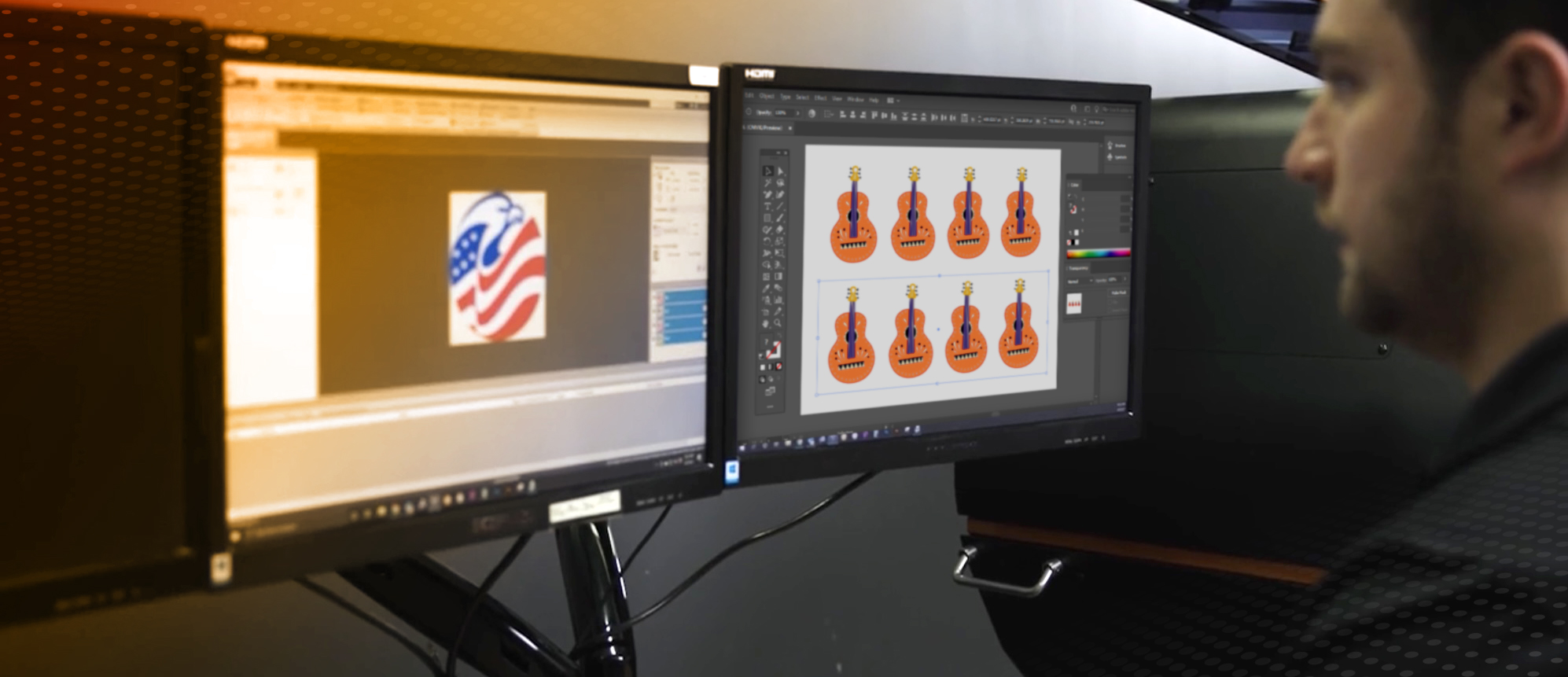

Provide advanced workflow features

Your printer software should allow operators to customize and build pre-defined workflows. This results in the ability to easily follow a repeatable process, ensuring consistency and repeatability.

A queue-based print job management function is also important. This allows you to drag and drop jobs on the platen with pre-configured parameters specific to the queue — and also lets you track the status of active jobs.

Feature the latest raster image processing technology (RIP)

RIP software performs some of the most critical functions in the printing process, including:

- Preparing artwork for printing through rasterization.

- Allowing you to size and place the artwork relative to the object you are printing upon.

The UV printer you choose must perform these functions properly while also fitting into your existing production environments. It is also essential to know the types of files that your RIP software will accept natively — without the need for exports or third-party conversions. The RIP you choose should take a broad range of standard image types, including those from common imaging and graphic art providers. In addition, the system should be able to read and process embedded color data from these files.

A prime example of this kind of RIP software is the LogoJET edition of Kothari Print Pro. This printer software is a powerful, capable, and customizable integrated RIP available in the UV direct-to-substrate market. This software incorporates all of the features discussed above — and much more.

Regardless of which UV printer you choose, the one thing to remember is that the software provided must meet the specific production and workflow needs of your business — while also being adaptable to new technology in the future.