There comes a time for any graphics-oriented business to break out of its comfort zone and try something new or stay the course of the tried and true. Businesses on a fast growth track or in areas where that business has become a one-stop graphics shop have to eventually explore the opportunities available with the many wholesale options for signage available today.

When it comes to sign business today, “It’s not your father’s Oldsmobile (or vinyl plotter),” as the saying goes. And times they are a changin’. We see it and embrace it with technology, new equipment and materials, and even social media.

For a lot of people, myself included, when starting and growing a business I wanted to have control. There, I said it out loud. My shrink would be proud. It took a lot of research, hand holding, and bottom-line accounting to break out of my business niche of work completed strictly in-house and navigate the wholesale possibilities.

Thankfully, the wholesale industry has also changed. Not only is virtually every signage product imaginable available by a wholesaler, but in today’s world these organizations offer much more than just product.

In order to take the leap of faith, it involves mutual collaboration for the shop to gain a certain comfort level. Remember, these companies also follow the same 80/20 rule of business as the rest of us, so it’s understandable they want the experience to be positive, profitable, and prompt so you return as a repeat customer.

So let’s dispel the myth that wholesalers are the cut-throat used-car salesman of the past (when they actually sold Oldsmobiles). We all want the same win-win outcome for a project. For that to happen successfully, we need to understand the process, educate ourselves on what to provide, and just like we do for our clients, manage our expectations.

With any custom project that comes through the shop, clients are looking for what I refer to as the Big Three: Quality, Price, and Time (QPT). An industry friend told me early on: “You can have two out of the three; but not all three.” If you want it quick and cheap, you are going to sacrifice quality. If you want high quality in a timely manner, it will cost you. Looking for high quality with a reasonable price? Prepare for it to take some time. The same should be expected from a good wholesaler.

Permit me to introduce myself

This article focuses on exterior signage. I’d like to begin by prefacing that every contact I spoke with wished to convey one thing loud and clear… know what permitting in your municipality allows for signage!

Permitting is a whole topic in and of itself, but it is imperative to check on this before discussing exterior signage. For free-standing signs, this means finding out the square footage allowed, the total out-of-ground height, and how far set back from right-of-way the sign can be.

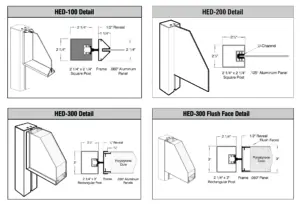

Let’s begin with non-illuminated products. Most shops would be familiar with large industry wholesale companies like Gemini for flat cut and cast letters and logos in a variety of materials. But when it comes to a dimensional sign monument/cabinet or post-and-panel systems, there are quite a few options by several manufacturers.

Depending on how involved and capable your shop is, there are wholesalers that can provide turnkey products or kits. Mostly composed of extruded aluminum components, wholesalers have the stock and equipment to cut, miter, and pre-fit those extrusions in standard or custom sizes.

These kits can be provided in a mil finish or custom painted with an exterior automotive-quality paint you can specify with a PMS color or standard color chart provided by the company. Faces are usually made of a sheet of aluminum (thickness determined by the size of the cabinet). Kits are usually broken down for shipping and require minimal work to assemble at your shop, probably as simple as assembling Ikea furniture.

With these products they are often decorated and lettered with vinyl that you can do on your own in-house or ask that the product be delivered already complete with either vinyl or masked and painted graphics. Depending on your skill and comfort level, you have options.

Post and panels, wealth, and taste

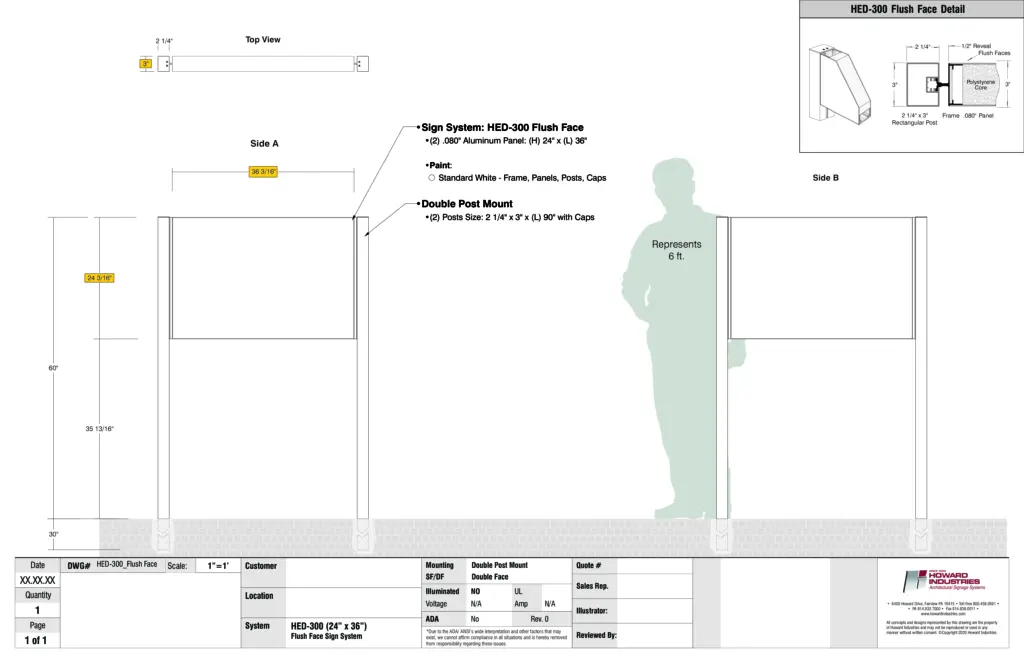

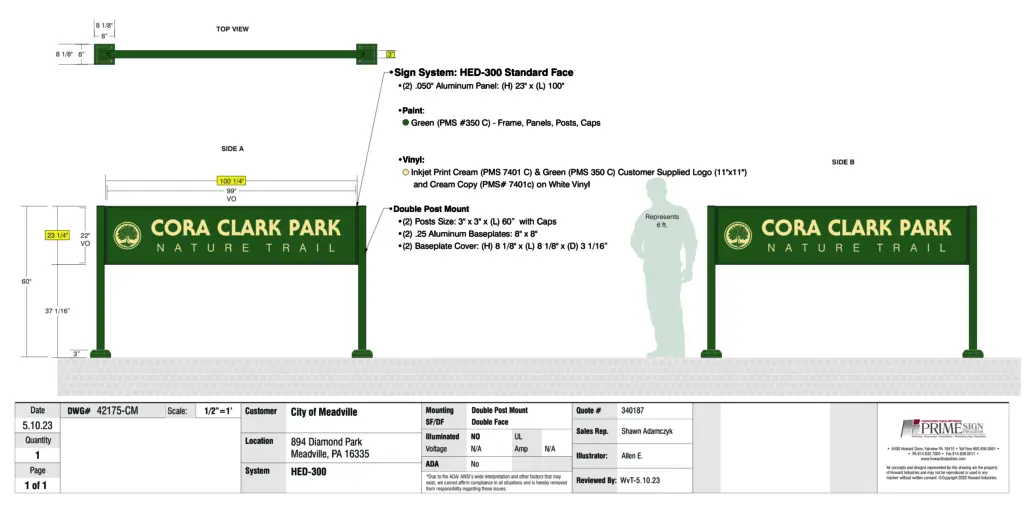

I spoke with Jen Miazga with Howard Industries in Erie, Pennsylvania about her company’s post-and-panel systems: “Howard Industries has always been known for providing high quality extruded aluminum post-and-panel sign systems; today we not only provide an extensive selection of that core product, but we have enhanced our internally illuminated cabinets and custom signage abilities, while creating our own interior sign system.” Miazga says. “Our core business is providing our exterior sign systems, complete with painted posts, hardware,

and panels to our sign industry clients where they can either apply their own graphics or have the option to purchase a complete sign with graphics ready to install.”

These non-illuminated products are the perfect stepping stone for those new to navigating the wholesale industry. There is a large market for permanent non-illuminated sign identification and wayfinding for businesses and schools, hospitals, and municipalities, just to name a few potential client groups. It gives you the opportunity to keep a standard of sign types for a project with similar extruded posts, panels, and painted colors. You control the graphics (usually cut or printed vinyl) or let the wholesaler hand it off ready to go.

“At Howard, we are able to help someone new to this type of signage with detailed drawings and specifications, and decades of experience with a staff that is ready to help,” Miazga says. “We have found our product templates and technical drawings can be very beneficial for our clients that need that for customer sign-offs or permitting purposes.”

Turn-around on wholesalers that offer standard post-and-panel systems is usually very expedient. Most will stock inventory of the specialty extruded aluminum posts and panel hardware. It just needs to be cut to size, prepped, and painted. That is the beauty of working within the standards of product types in your initial drawings to your client. Throw anything outside the standards and be aware that will add costs and time for the custom work.

These product types on smaller wayfinding signs can usually be packed and sent with standard ground shipping. Larger sizes will come via freight.

Monumental opportunities

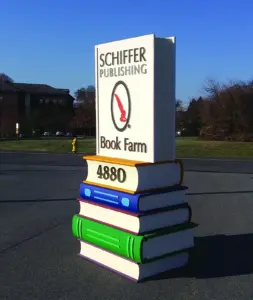

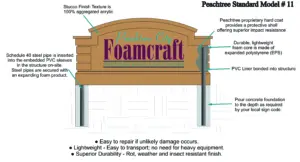

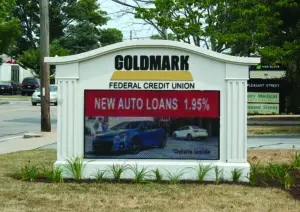

Foam monument systems offer another turnkey alternative to providing clients with identification signage that is a lot simpler than you would expect. I spoke with Mike Fetter, sales and marketing director at Peachtree City Foamcraft with locations outside of Philadelphia, Las Vegas, and Atlanta.

“Our three locations allow us to service the entire continental United States as quickly and freight-friendly as possible,” Fetter says. “Our monuments offer sign companies large and small a product that can compete directly with fully constructed masonry projects at an economic price point.”

The foam monuments made of encapsulated polystyrene (EPS) have come a long way over the years and are available in a variety of standard and custom configurations.

These products are typically produced by hot wire cutting large billets of EPS foam that are glued together and the entire exterior of the foam is coated in a hard coat finish that protects and encapsulates the foam structure from the effects of freeze-thaw, mechanical impact, and abrasion.

“Having been manufacturing monuments for over 30 years we have seen exponential improvements in polymers. Today, our proprietary Poly-Armor finish is extremely durable and allows us to maintain detailed carvings and shapes. Our final finish is a robust Master Wall exterior product available in a fine stucco texture. It is available in dozens of standard colors as well as custom color formulations,” Fetter says.

The monuments have embedded PVC post sleeves, and to install them galvanized steel posts can be purchased

locally or supplied. These posts are slid into the larger PVC post sleeves and are held into place with expanding high-density urethane (HDU) foam at the time of installation.

Most monuments involve hand-digging two to three post holes, a bit of concrete, and two to three people to guide, level, and plumb the structure. An experienced sign installer will find these a breeze to work with and novices will enjoy the simplicity of installing what looks like a ton of bricks!

Over the years, Peachtree City Foamcraft has added custom stone, wood, and other architectural elements to address the ever-evolving requests of environmental and signage designers.

Fetter adds, “We started with just a few basic monument models with a stucco finish. We still do a good deal of those monuments. We have been given regular challenges to provide something different and today we can

reproduce nearly any type of stone, architectural embellishment, or even create faux wood. Many of our initial customers start with a project utilizing one of our standard models. Once they are comfortable with the product, our process, and capabilities, their imagination takes over. Customers can provide their own graphics or sign panels or we can provide an absolute turnkey product ready to install. By adding internal support framing we

can even have electronic message centers (EMCs) installed in our monuments. For people new to selling these products, I always ask them to contact a local mason or contactor to build an actual brick-and-mortar

structure; once you see those costs and time frames involved the value of this product really begins to shine.”

Peachtree offers a large volume of support materials for permitting and installation, as well as detailed drawings for its customers. Samples are available upon request so you can show your client the durability of this unique product.

Product is crated with a full frame and wrapped in clear shipping plastic. It is easily surveyed upon receiving for any shipping damage. These products always come freight; if you don’t have a shipping dock you can arrange delivery with a short truck and a lift gate. Most monuments weigh around 250 to 350 lbs. with the crate, so unloading and loading for install is manageable with a couple strong shop hands. According to Fetter, most monuments require four to eight weeks to produce after final approval.

Sympathy for the details

For electric, custom-fabricated cabinets and channel letters there is another tier of wholesalers that can provide that. These products are almost always provided turnkey and ready to install. There are plenty of good reasons for that.

Keep in mind that over 90% of new signage when illuminated internally is LED and running low voltage. However, since these signs are exterior and require a permit, the wholesaler needs to be UL or MET certified and in a growing number of municipalities. The sign will require a visible tag with the referenced UL or MET number, manufacturer, and phone number. You can always add your own local calling card next to it, but by code it may have to be there.

We all know that puppy-dog-eye client that comes into our shop not knowing a thing about graphics and layouts. They look to us as their consultant to deliver a quality product. Good wholesalers are going to do the same for you once the process and relationship is started.

To begin, it’s important to get the right information over to the wholesaler as clearly and specifically as possible. Just like that client that brings in that pixelated logo their nephew drew up for their business, the old adage remains garbage in — garbage out.

Start by sending clear drawings. At the very least, send your artwork as a vectored PDF so it can be reviewed from the wholesaler’s fabrication perspective. Did I mention vector artwork? Most of this custom work is going to be produced by CNC machinery and that always follows vector lines.

I visited Brian Lawton at Diversified Signs and Graphics in York, South Carolina. Diversified is a large wholesale

operation that provides architectural signage and installation services for companies in the industry as well as established sign brokers.

“You would be surprised at the number of requests for job quotations with artwork supplied that is so pixelated

you’d be embarrassed to print it out on your desktop printer. It is so important to view the artwork in vector format so we can review the art for machining down the line. Sometimes art will need to be slightly altered. For example, a certain stroke width on a font is necessary to embed LEDs in a channel letter,” Lawton says. “Hand in hand with good artwork comes a good understanding of sign codes to determine what is allowed, how large, and who is responsible for handling any final electrical connections. For the latter, we suggest to our customers that the client provide their electrician to do that. Some installers are qualified to make that connection but be aware some communities require a licensed electrician to do that connection. Do not underestimate the permitting and electrical work involved in this type of sign work. Once we have addressed those issues up front, we are ready to explore a variety of sign types and construction and begin getting together quotes to review.”

Diversified Signs offers virtually every type of custom architectural sign type for monuments, wall mounted signs, and channel letters.

“Our business is a good mix of established sign companies and brokers that know exactly what they want and newer small to medium sized sign companies that are breaking into the architectural sign market. For the latter, we have years of experience and our team is well versed in helping educate customers on what is needed and what to expect in the process.

“With so many options available today, we can quickly make suggestions to nail the desired look on a high-end project or value engineer others that may involve multiple locations. It’s a good idea up front if our customers are proactive with their clients to set realistic expectations of budget, look, and time frames,” Lawton explains.

The lion’s share of this type of sign work is new construction, so a lot of coordination is needed with owners and their general contractor. You are providing the sign but the final client needs to understand there may be coordination involved in running dedicated electrical lines or possible building permits for the foundations of some architectural monuments.

There are a lot of unknowns during new construction, and it becomes a very fluid environment working behind other supporting trades before the signage goes in. The more you are aware of this and upfront with your client the better the chance of having a flawless experience that will make you want to do more.

The second largest segment of this market is the rebranding of multiple locations. You might not be able to land a contract with a large bank account, but think of all the businesses you already do work with that have multiple locations, and once a new logo or look is launched there are tremendous opportunities for signage.

For custom architectural signage like this, it is best inspected and picked up at the wholesaler’s location with your own vehicle and trailer, have your sub-contracted installer do that for you, or if you have a wholesale source similar to Diversified Signs, have them do the whole job. There can be advantages to having the fabricator also install.

Navigating the world of exterior wholesale signage can seem a bit overwhelming initially. It’s important to do your homework up front before contacting a company. Know your local permitting constraints and procedures, do a good site survey to determine any electrical needs or potential issues lying below the ground,

and get good quality vector artwork.

From there, let your new wholesale contact guide you through the rest of the process, and always remember to manage your client and your own expectations that are realistic so all parties win at the end of the day!