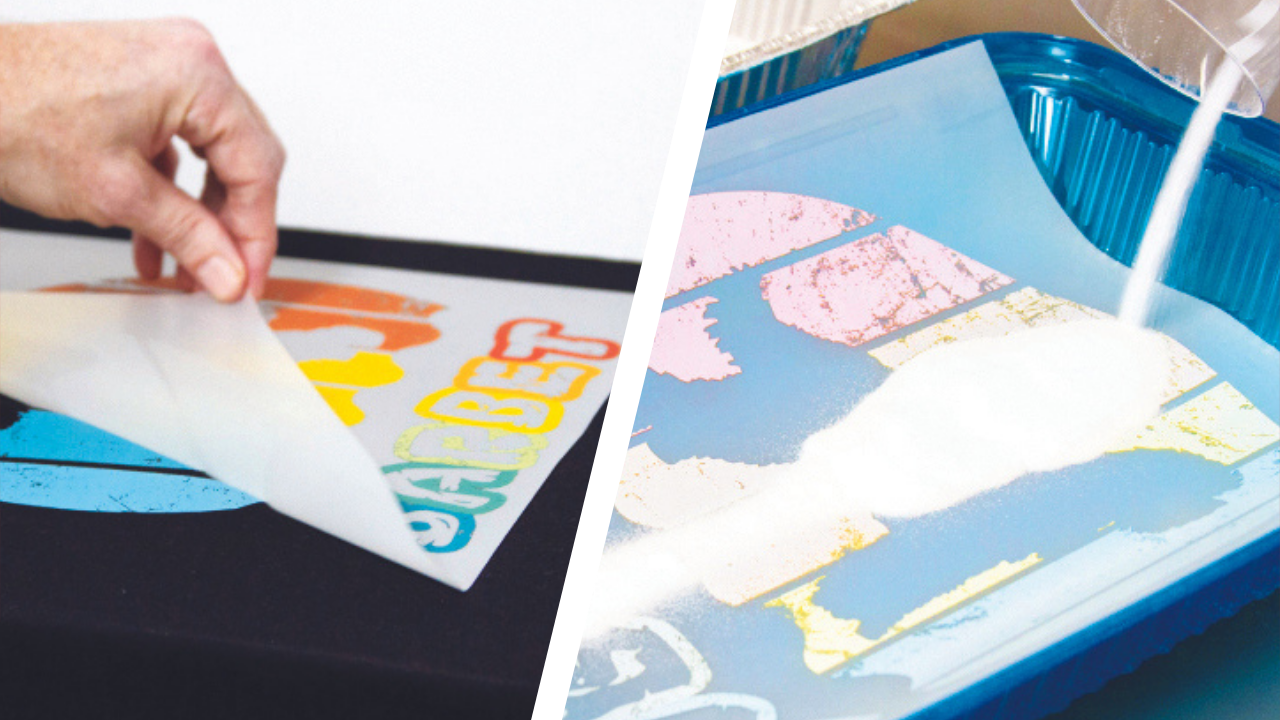

Compared to standard apparel decorating techniques like screen printing, direct-to-film (DTF) printing is very much in its infancy. The printing process premiered in 2021, with mainstream adoption taking place in late 2022. DTF involves printing a graphic onto a piece of film using multiple water-based colored inks, adding adhesive powder, and curing the film. The film is then applied to a garment with heat and pressure from a heat-press machine, resulting in a highly detailed and long-lasting graphic. This method can be used to decorate a wide array of apparel and other items.

As to be expected with new tech, there are more questions than answers when it comes to DTF safety. “Can powder cause health issues?” “Do my employees need to wear a mask?” “What can my staff do to avoid inhaling fumes directly?”

“There’s a lot of varying safety information in the DTF space, especially as it relates to the curing of DTF powder,” says Taylor Landesman, vice president, Lawson Screen & Digital Products. “The industry consensus is the powder could be harmful if not properly purified when going through the sublimation phase from a solid to a gas.”

Daniel Valade, product manager, Roland DGA, agrees. “While our DTF powder is designed to be safe for use in printing processes, like with any fine particulate matter, there is a potential risk if it is inhaled or comes into direct contact with skin over prolonged periods,” he says.

The bottom line is, if not handled appropriately, DTF printing can be harmful to your employees and customers. Print businesses should do their research before bringing equipment in-house, follow protocols, maintain a clean and organized workspace, and consider products that are safety certified.

Environment

“The growth of this decoration method, especially in the home-based market, drove our desire to offer a powder that meets independent safety standards,” says Landesman.

Paisley Jo Designs is an example of a growing at-home business utilizing DTF technology. Kim Johnson runs the two-person business on the second floor of her home in Phoenix. She owns an Epson Hybrid DTG/DTF F2270 printer with Oeko-Tex Passport Certified inks, a Vastex PTF-100 single sheet powder shaker (a fully enclosed powder shaker system), and an Equipment Zone EZ Cure DTF sheet dryer.

“We definitely did our research before bringing DTF in-house,” Johnson says. “My main concern was making sure the powder is Oeko-Tex Passport Certified. This ensures it’s safe for adult and children’s apparel. We also use a fume extractor, which helps eliminate inhaling fumes from curing,” which she says is especially important in a home office.

Johnson’s advice to other print shop owners is “to use common sense safety measures when handling DTF materials.” She foresees even more safety measures being implemented to ensure the safety of employees and consumers in the future.

Stoked On Printing in Las Vegas, Nevada, is a much larger operation. The full-service merch company specializes in custom T-shirts, screen printing, DTF printing, embroidery, promotional goods, and company swag. The business recently scaled back on DTG, replacing it with DTF. The Stoked On Printing team runs an STS Mutoh 60” DTF printer.

“When it comes to digital printing in general, you really need a nice clean environment and for it to be controlled, which lives right alongside a very safe environment,” Kevin Oakley, co-founder and chief revenue officer, says. “We ensure there are no tripping hazards, no water or liquids around or on the ground, which can lead to slipping, and we also have a well-ventilated space.” When asked if he completed any research on the health and safety of the DTF process prior to purchasing their DTF printers, Oakley said “with the inks being pretty eco-friendly we really honed in on the powder and made sure we had space to put in a well-ventilated area. We were pretty familiar with the powder as we had used it in screen-print transfers.”

A safe environment is most likely already top of mind at most print shops. “It’s a big sticking point in our business that we need to keep work areas clean and organized as that is the main reason accidents and injuries happen when there are tripping or fall hazards,” says Oakley. “This is no different than DTF workspaces, but it should be taken to another level because digital printing is very finicky.” Stoked On Printing also makes sure all its supplies comply with general safety and Consumer Product Safety Improvement Act (CPSIA) regulations.

To ensure this secure space for employees who are DTF printing, Valade says, “it’s essential to prioritize good ventilation and air quality, provide appropriate personal protective equipment like gloves and masks, and offer thorough training in handling the equipment and materials. Regular maintenance of printing equipment, keeping the workspace clean and organized, and having access to material safety data sheets are also important.”

Certifications

DTF safety measures don’t just fall on the print shop owner. Vendors can also take extra steps to ensure products are certified.

Lawson Screen & Digital Products DTF powder received Eco Passport Certification by Oeko-Tex in 2024. As an Eco Passport Certified Product, independent, third-party analysis determined that Lawson DTF powder is safe for the environment and can be used in sustainable and environmentally responsible textile production as each compound meets stringent sustainability, safety, and regulatory criteria. Lawson’s DTF powder is also compliant with Reach and Zero Discharge of Hazardous Chemicals (ZDHC) guidelines. (The ZDHC is a program committed to eliminating hazardous chemicals from textile production and manufacturing.)

“Because the Eco Passport safety certification is widely considered a top safety and chemical compliance, getting Lawson’s DTF powder Eco Passport approved allows us to offer a DTF powder that is certified by a third party to prove it does not include substances that are harmful to human and environmental health,” says Landesman.

The consumable components used in the DTF process with the Roland DGA BN-20D printer also have the Eco Passport Certification. “The Eco Passport Certification by Oeko-Tex highlights our commitment to environmental responsibility and health and safety,” Valade says.

“It signifies how Roland DGA’s products – namely the inks, film, and powders – are produced using eco-friendly processes and are safe for human use. Achieving this certification reinforces the trust from our customers and partners who are looking for sustainability and safety in their products. Overall, this aligns with Roland DGA’s dedication to meeting the highest standards for environmental and health considerations.”

What to consider when bringing DTF in-house

Apparel decorators should review a few factors when adopting DTF technology in-house: workflow, quality of equipment and products, staff training, sustainability, support, and education.

“Understanding the complete workflow is crucial. This includes not just the printing process, but also pre-treatment, curing, and finishing. Each step is vital to ensure the final product meets quality standards,” Valade says.

The quality of the printer as well as the consumables are also important. “The choice of inks, films, and powders greatly affects the durability, feel, and appearance of the print,” he says. “Using high-quality consumables not only produces better results but can also reduce waste and increase efficiency.”

Employee training and skill development must be addressed because DTF involves specific techniques and knowledge to run efficiently and achieve quality results.

The print shop is the last group in a long chain to touch the final product before it’s received by the customer. “As the industry moves toward more sustainable practices, understanding the environmental impact of the inks and other consumables, and how to dispose of them responsibly is extremely important,” Valade says.

Landesman says the biggest consideration for bringing DTF in-house is support. “The cost of the machine is not how much you pay, but the total cost of ownership,” he says. “I’ve heard countless horror stories from current clients who at first tried a cheap DTF machine, only to struggle with support, parts, and help. The piece of mind that comes with finding a vendor that offers U.S.-based support on both the equipment and supplies is priceless.”

Last, but certainly not least, continuous learning and education must be top of mind for those in the DTF space. This includes the latest advancements, certifications, and new materials and equipment. “The industry is evolving quickly, and being aware of new techniques, materials, and equipment can keep a business competitive,” Valade says.

The future of DTF

When asked if Landesman foresees strict rules and regulations, specifically in states like California, arising in the DTF printing market, he says, “The regulatory landscape is constantly evolving and may have a spillover effect in the DTF space. States like California are traditionally on the vanguard of advancing the most onerous restrictions, which is why Lawson is constantly testing and doing research and development to provide better and safer products, no matter where someone is located.”

Valade agrees. “In states like California [where Roland is based], known for strict environmental and occupational safety standards, it’s likely that more specific and stringent regulations could be introduced,” he says. “These regulations may focus on reducing volatile organic compounds, regulating the use of chemicals in inks and solvents, enforcing stricter waste management practices, enhancing safety protocols, and requiring labeling and transparency about the impacts of materials used. Businesses in the DTF printing sector should stay informed and prepared to adapt to these potential changes to ensure compliance and maintain consumer trust.”