During the early pandemic, alcohol sales soared. Today, sales continue to remain high. Wine tumblers are versatile and convenient to bring camping, to the beach, or even lounging by the pool. They make a great gift for every adult in your life — especially if they can better reflect the recipient’s personality and interests. Enter print-on-demand for wine tumblers.

E-commerce continues to rise, even as life and in-store shopping return to normal. There is a positive correlation between consumers continually opting for e-commerce and the demand for personalized gifts. Print-on-demand wine tumblers bring numerous benefits to an e-commerce business, including the flexibility to print a single piece or hundreds, saving time, and its cost-effectiveness.

Print-on-demand also allows you to offer your customers more options. By offering a variety of products, businesses reduce their risk of customers seeking alternatives elsewhere, thus capturing a greater wallet share.

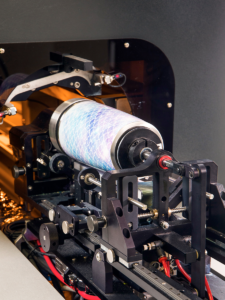

Utilizing cylindrical printers for faster production

When it comes to wine tumblers, cylindrical printers make a great fit for your print-on-demand needs. By utilizing API paired with a barcode scanning system, printers can connect to e-commerce shops and produce personalized print-on-demand wine tumblers.

Barcode scanning systems allow a user to seamlessly flow between hundreds of pieces of artwork. To begin the process, adhere labels with corresponding barcodes on the bottom of each wine tumbler. Scan the barcode and the printer will pull up the corresponding artwork from the database and begin printing. After a mere 30 seconds of drying time, remove your tumbler and repeat.

Cylindrical printers are also known for their easy changeover between drinkware — from wine tumblers to water bottles and beer glasses. Offer customers endless drinkware options, all at a minimal effort to you.

Adhesion: How digital ink sticks

There are two types of pretreatment for adhesion to ensure ink sticks to your choice of drinkware: plasma and corona. Either of these adhesion systems can be integrated into a cylindrical printer.

Both systems have the same end goal — changing the surface tension of the substrate — but different execution. Plasma pretreatment is a flame process that utilizes the plasma of a flame to change the surface tension of the substrate; whereas corona pretreatment uses an electrical charge. Due to the nature of the pretreatments, the plasma is the more powerful of the two.

Design techniques

Simply put, digital printing allows easier customization as it bypasses using sublimation paper, cutting to size, and heat sealing by printing directly onto a tumbler with ink. By opting to print digitally, you not only eliminate substantial waste but also save time.

Many printers offer numerous other specialty design techniques including contour print, UV spot varnish, matte print, and photographic print.

Easy 4-step process

Print-on-demand for wine tumblers utilizing cylindrical printers is easy. The four-step process is as follows:

- Receive your order

- Pick the drinkware to print on

- Scan the barcode for the corresponding artwork

- Step back and let the printer do its thing