Now more than ever, companies are changing and adjusting to the new realities of the world. With continuing restrictions on travel, events, social gatherings, and phased openings of businesses, the world has been forced to adjust to the next normal—and it has to do so quickly. Especially now, with the peak holiday season being over, companies should consider their options to properly keep up with supply chain demands for the new year.

Months ago, many businesses shifted away from what they usually produced or offered to deliver entirely new products. For example, apparel companies pivoted from creating shirts, pants, and other items to developing new PPE that hospitals desperately needed. Promotional product distributors needed to sell or give away their stock of hand sanitizer to the general public. Even distilleries were jumping in to shift alcohol production to make hand sanitizer. All industries had to adjust business models and production lines to help out their communities.

Businesses that did not outsource their printing needs but had maintained their own in-house capabilities were only minimally impacted when they shifted production. For example, apparel decorators that needed to switch up production, especially for high-volume output, did not need to wait for additional heat transfer labels from an outside source to produce ample stock at high speed at the exact moment they needed it done. Promotional products companies with inkjet machines in-house adjusted their labels and messaging and got products out the door faster without an additional step.

When supply chains were and still are delayed, derailed, or completely shut off, those who had full control of their own production were able to smoothly and efficiently modify processes to fulfill the needs of their customers.

The next normal

So, what does this mean for businesses heading into the next normal? While no one can appropriately define what that entails or looks like, one thing for sure is that people and businesses alike will be more cautious about business plans. According to a recent study by ThomasNet, a whopping 61% of manufacturers said they are looking to re-shore their supply chain. That is, they aim to bring production and manufacturing back to the company’s country of origin.

However, this growing trend only just recently started. Companies are only now beginning to think about bringing production in-house and giving it a shot. They see the value in implementing in-house and high-volume production printing to their internal operations, especially if it benefits them now and, eventually, in the long run. So, if not now, then when?

Here are some of the benefits of in-house and high-volume printing to consider:

Retain complete control of your production

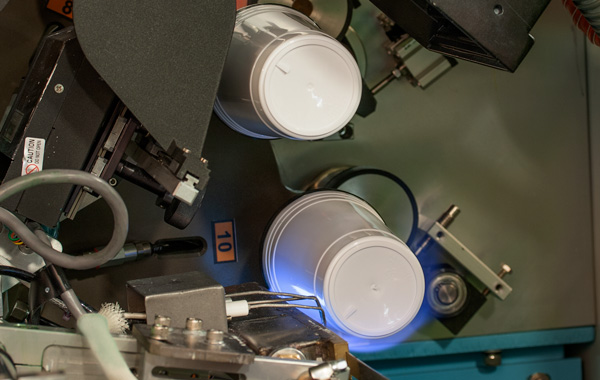

Bringing high-speed printing in-house will give you complete control of your production. During turbulent times or faced with an increase in demand, businesses that can print in-house rapidly have a competitive advantage. With such capabilities in place and no need for outsourcing, they can print quickly and in high volume. A great example of a high-speed printer that can easily be implemented in-house is a UV-LED digital printer, which can print full-color graphics on various products, including hard substrates like cups, glasses, water bottles, etc.

Shorter lead times

While this is an obvious benefit of in-house printing, the background around lead times is that everyone has them. Anytime you are purchasing products and services from another source, there will always be delays due to processing, packaging, shipment, and receiving. These can be long or short, depending on where the product is coming from. With in-house printing, you won’t need to wonder or wait for products to be finished.

No minimum order quantities

In many cases, minimum order quantities can be quite high. This, in turn, leads to turning away business if your minimum order from a supplier is much more than a customer is requesting.

Keep current with shifting trends

One of the most important benefits is being able to keep up with rapidly shifting trends. Companies that can capitalize on a trend and sell products with a popular meme or character will be ahead of their competitors. This is also true for major global sporting events like the Summer Olympics scheduled for this year. Companies typically need to produce sufficient products well ahead of a big sporting event to ensure they have the right items for whichever team wins.

The next step

Now that you’ve considered the benefits, you can begin to think about implementing in-house, high-volume printing to be better prepared for the next normal. It can be challenging but taking control of your supply chain requires analyzing your business practices to see where the bottlenecks are.

Ask yourself: During this time of crisis, which processes held up the business from proceeding? In the case of many companies, it was labeling and product decorating. Many apparel decorators rely on heat transfers from other countries as much as drinkware companies rely on printed products from other countries. By bringing these processes in-house with high-speed innovation, decorators can eliminate uncertainty in a crisis, improve speed to market, and print as many or as few products as needed without the worry of minimum order quantities.