Are your customers demanding exact Pantone color matches for their logos or need multiple colors matched for a design? But you’re not sure how to do it or how complicated the process is? Fear not! Exact and repeatable color mixing is easier than you may think.

As consumers become more fashion savvy, so do their demands for better color matches. Pantone is the color standard most refer to. Their color books and subsequent color values (also referred to as PMS colors) are communicated globally.

Here are some easy-to-follow tips to de-mystify the process.

Here are some easy-to-follow tips to de-mystify the process.

First, be sure to obtain an updated Pantone Graphics/Print color book. Over time, the colors in the book can shift or fade, new colors may have been added, and often, the colors from one year’s book to the next year’s may even vary. It’s not a perfect system, but getting as close to a color match as possible is the goal.

Pantone makes several types of color books, but the one most often used by screen printers is the “Uncoated (U)” or “Coated (C)” Graphics/Print values. This terminology stems from when inks were printed either on coated or uncoated (porous) paper, which would make the ink either shiny or more matte.

Invest in a good color matching system. Be sure the ink manufacturer of your color matching system has an accessible, easy-to-follow online formulation calculator. Choose one with open access and no complicated registration process.

There are typically several types of systems you can choose from:

- Ready-for-use mixing system – A simpler, finished ink system consisting of pigments premixed into a base.

- Color concentrates – An ink system that consists of curable pigments you can blend into a variety of available bases, typically at a ratio of 1 part curable pigment to 1 part base.

- Pigment dispersions – These are high pigment concentrates that are not curable on their own and must be mixed with a base. Typically, they are mixed at a rate of around 2 or even 3 parts base to 1 part pigment. Use care to avoid over-pigmenting or creating an unbalanced ink that may not cure or fuse properly.

Please note: Translating printed color to inks requires some considerations. For example, when color matching using plastisol inks, remember that the finished print can either be glossy or matte, depending on the ink. However, when using water-based ink, the finished print will usually be matte. Also, be aware that color can shift — albeit slightly — and look different from the original depending on the ink type used. 156 or 160 are the standard mesh counts used when verifying colors.

Screen printing tools to invest in to create the most accurate color matches

- A weighing scale – Invest in a good, accurate scale. The accuracy of your color matches depends on it.

Depending on the amounts you want to measure, it’s important to consider the weight range and sensitivity of the scale you’ll require. Do you want to weigh quarts or pints? Then you’ll need a scale that can weigh at least 1,500 grams with 0.1-gram accuracy or better. Keep in mind that you’ll need to factor in the container weight.

If you mix larger quantities, such as multiple quarts or a single gallon, then you’ll need a scale that can accommodate 5,000 grams with at least a 1 gram accuracy. If you want to mix both quart and gallon sizes, the scale you need should be able to weigh 5,000 grams with an accuracy of 0.1 gram.

- A nice spatula can be a handy tool. Many ink mixers have their favorite and don’t like to share. They have been known to keep them over many years, just like a chef in a kitchen has their favorite knives.

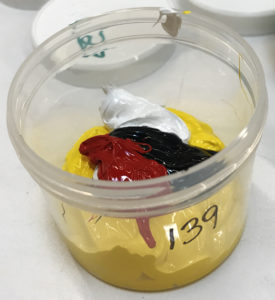

- Empty buckets (pint, quart, or gallon-sized or however much you want to mix) – I prefer clear or translucent ones so you can see any unmixed ink on the sides. And don’t forget the lids to store leftover inks and keep dust and dirt out between print jobs.

Once you have a PMS color you want to match, go to the formulation software for the ink brand you’re using and look up the specific PMS color value formula. Generally, the formula is in gram quantity per color.

Choose the amount you want to mix – This depends on how much of that color you need for the job you are printing. Most software applications allow you to choose a custom amount or standard pint, quart, gallon, or pail size.

Most ink software can help estimate the amount of ink needed by asking you what mesh counts are being used, the size of the area printed, and the number of impressions. It will then give you an estimate of the ink required per color.

Place your container on the weighing scale and tare it to 0. Follow the formula in adding the various colors you need to get the desired PMS color value. Remember to tare the scale to 0 between each color addition!

Add the larger ink volumes first and coat the inner walls of the container with the first color (usually a mixing white). Extra care must be used when adding the smaller amounts of ingredients. Be as precise as you can in weighing the amounts. Mix well!

Always test print your thoroughly mixed ink through a 160 type mesh with proper emulsion thickness and cure the ink at the required temperature before checking for color accuracy. Be sure to wait for the cured ink to cool off before checking, as some pigments will shift when heated.

Follow the above steps and tips, and you’ll be a color mixing pro in no time!

Tune into the video below to see the color mixing process first hand.