Try This: Rotating Display Table with Mirror Acrylic

Learn how to create this eye-catching rotating display.

Download the design files and follow the tutorial below to create this eye-catching rotating display.

Required materials:

- 1/2 sheet TroGlass Mirror rose gold

- 1/4 sheet MDF 1/4″

- 1/4 sheet TroGlass Clear 1/8″

- 1/4 sheet TroGlass Clear 5/16″

- 1 sheet synthetic laser paper 300g

- Ball bearing with 42mm outer diameter

- Covering material

Note: TroGlass is used in this example, but you can use an equivalent cast acrylic glass from another manufacturer.

Machine used:

- Speedy 400 flexx, 120/50W

- 2″ lens and 2.85″ flexx lens

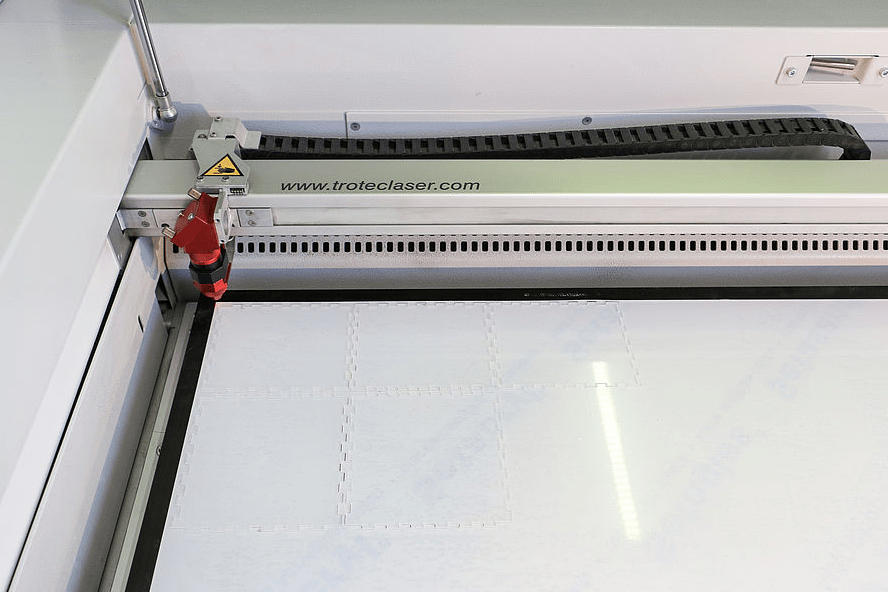

- Vacuum table with honeycomb cutting grid and acrylic cutting grid

Note: For this sample, you can use any laser machine from the Speedy laser engraver series, or an equivalent from another manufacturer. Consult your manual for settings.

Tips: Adapt the size and color of your display table to coordinate with the item being displayed. Our application is lit from the inside with battery-powered LED lights. If you do not want to illuminate your display, you could replace the TroGlass Clear materials with a cheaper material such as MDF.

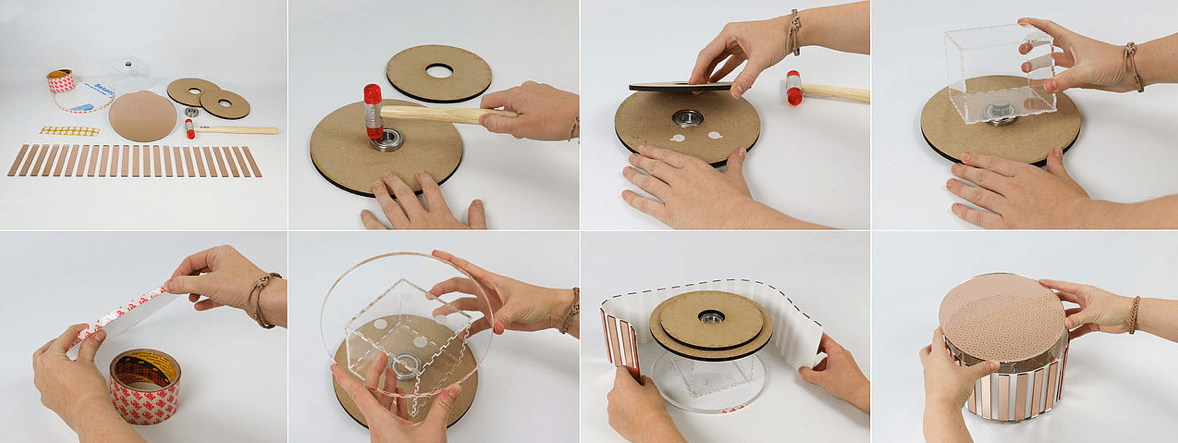

Step 1:

Images courtesy Trotec

Import the graphics files and adapt them to your requirements. Then send the graphics to your laser.

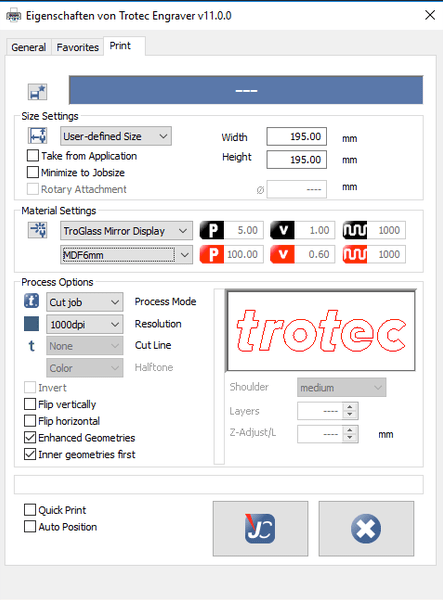

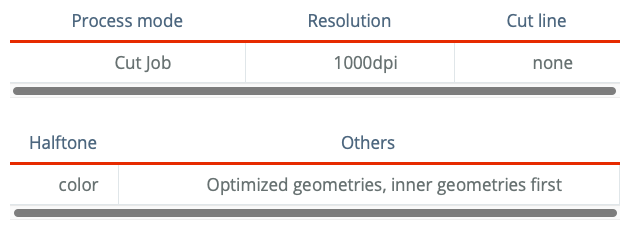

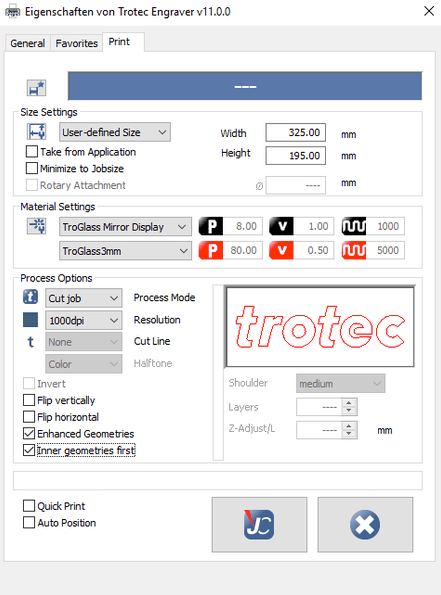

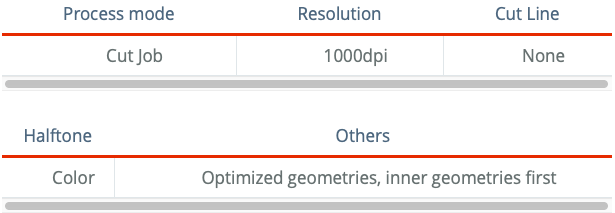

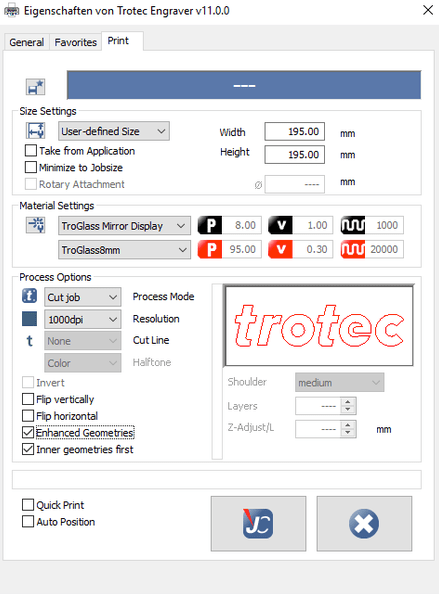

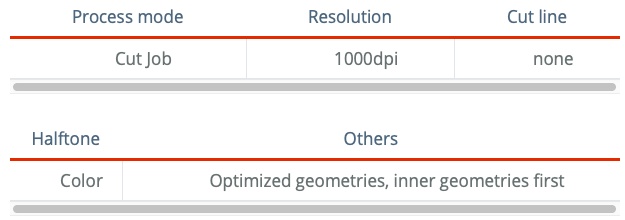

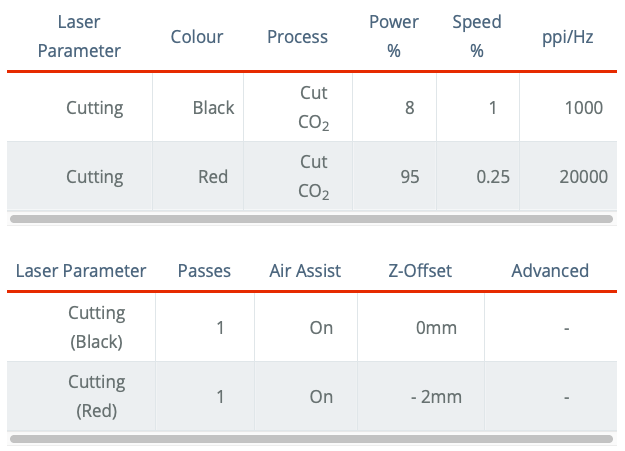

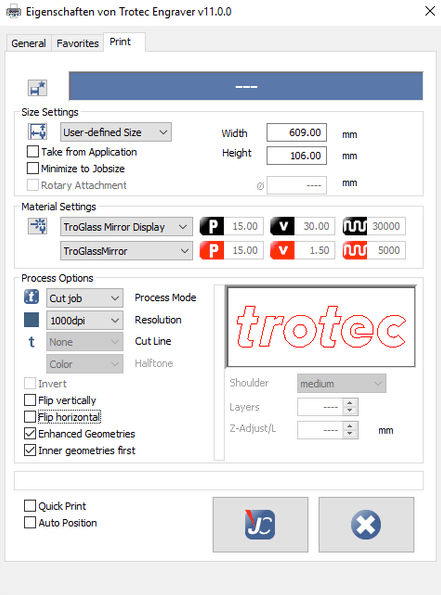

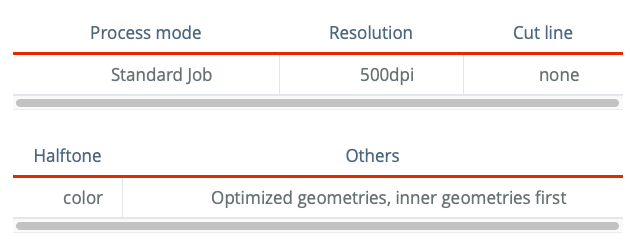

Start with the two circular graphics for the MDF, using the following settings:

The small circle with the blue contour (the blue contour is only for a better overview) will be used to attach the cube to the ball bearing. The size of this circle is determined by the inner diameter of your ball bearing + 0.2mm/.008″ kerf.

Step 2:

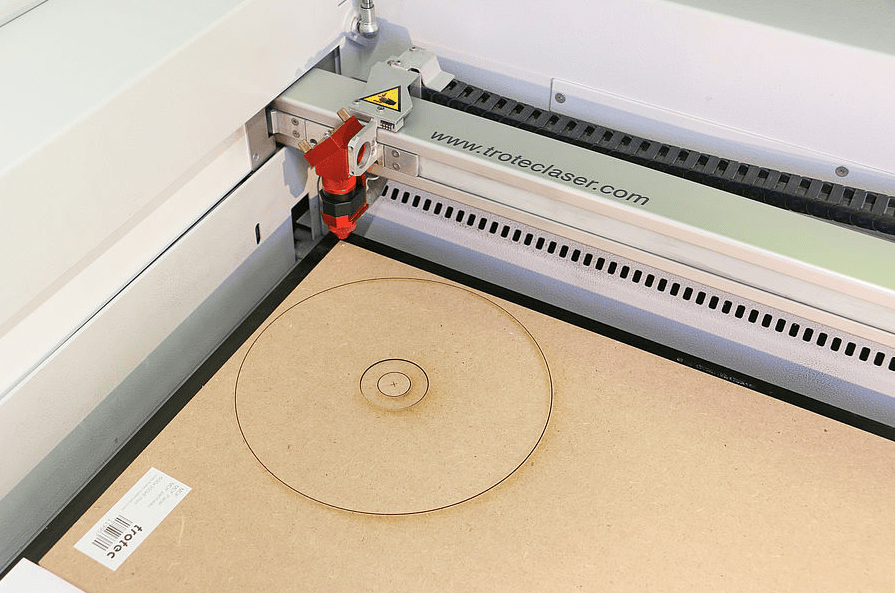

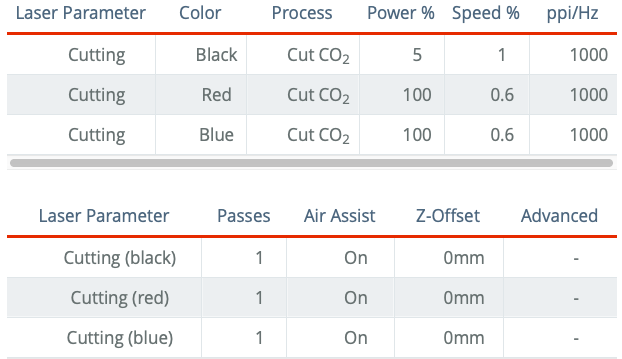

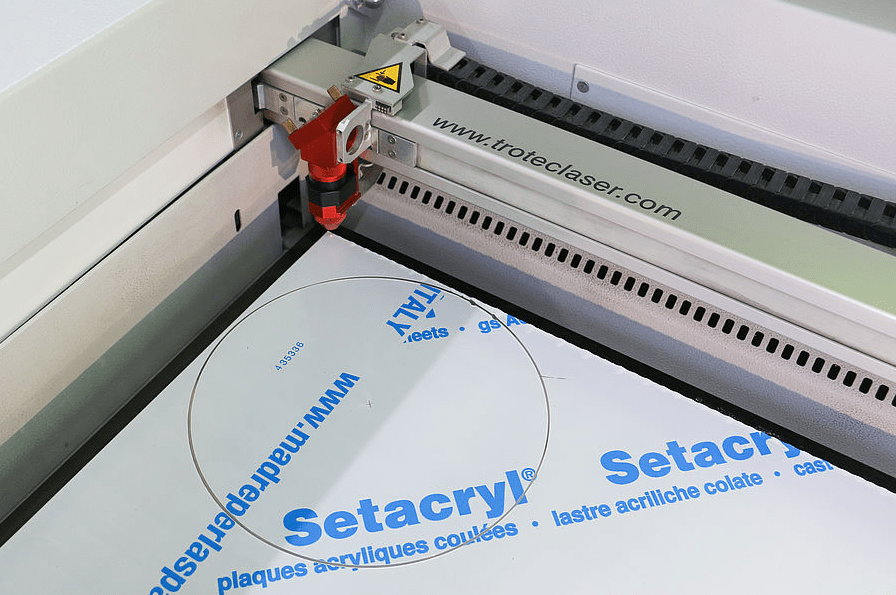

Put the 2″ lens into your laser machine, and then place the MDF on the honeycomb cutting pad. Be sure to cover the remaining working surface to create a vacuum. The parameters may vary depending on the laser machine you’re using and the laser power available.

To cut even cleaner edges, replace the large nozzle with the nozzle with a small hole diameter. (This works well for wood cuts.)

Step 3:

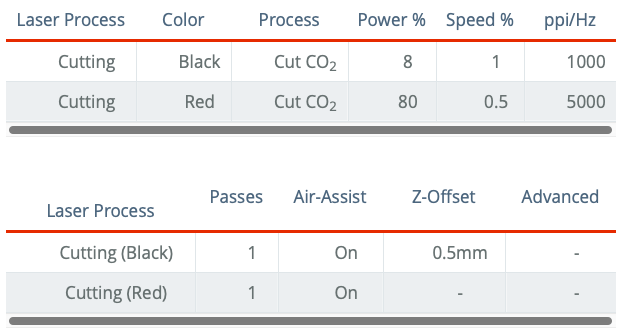

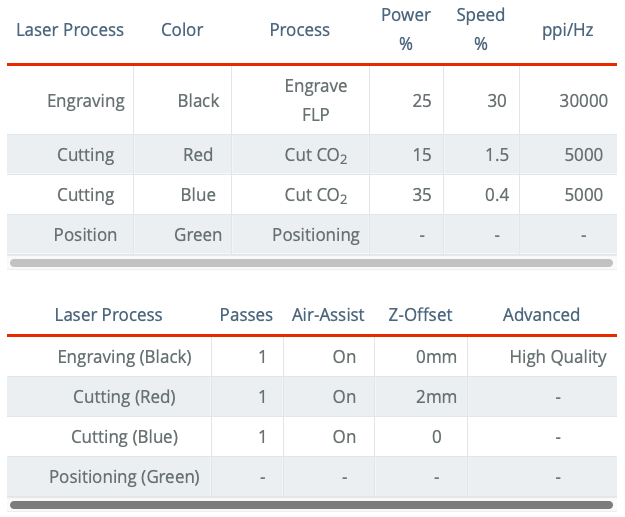

You can position LED lights in a transparent cube made of TroGlass Clear within the display. We then attach the small MDF circle (Ø20.2mm) with acrylic adhesive to let the cube rotate around the ball bearing. Send the individual parts of the cube to your laser with the following settings:

Step 4:

Place the TroGlass 1/8″ on the honeycomb cutting table in your laser and cover the remaining working surface to create a vacuum. The parameters may vary depending on the laser machine used and available laser power:

You can cut the TroGlass Clear parts on a honeycomb cutting pad or on an acrylic cutting table. The cuts produced on the honeycomb table will not look as good as those cut on an acrylic table, but these parts are not visible final display.

Enter 0.25mm as the kerf to keep the pieces strong when joined together.

Step 5:

A disc of 5/16″ thick TroGlass acts as a side panel support. The paper strip with the TroGlass Mirror rectangles will be glued on this later. Send the graphic to your laser using the following settings:

Step 6:

Place the TroGlass 5/16″ plate in your laser and cover the rest of the working surface completely to create a vacuum and reduce the risk of fire. The parameters may vary depending on the laser machine used and available laser power:

Step 7:

Finally, we produce the most visible and most important parts of the display from TroGlass Mirror. Send the graphics with the rectangular side parts and the engraved circle graphics individually, but with the same settings to the laser. This will help you better position the two jobs later.

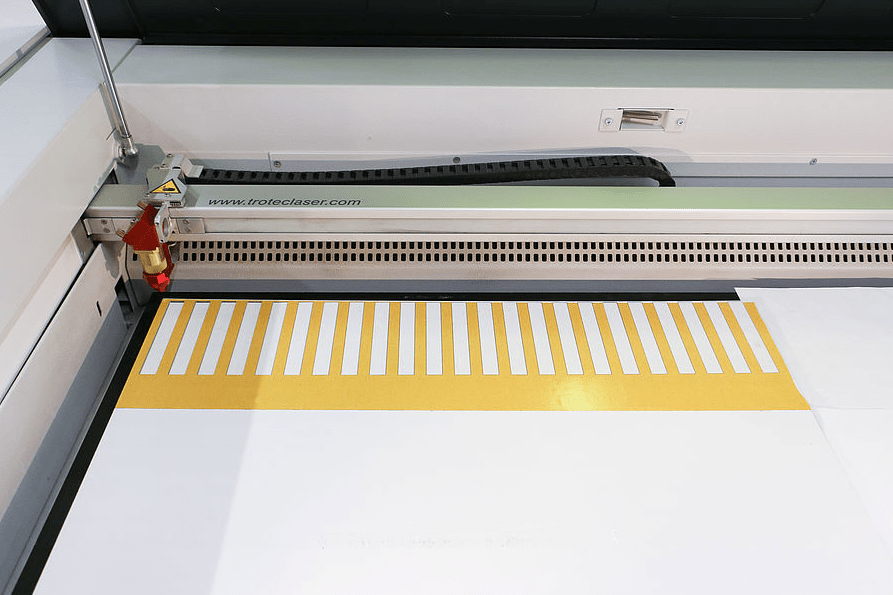

Step 8:

To edit and adapt the TroGlass Mirror material, add the 2.85″ flexx lens to your laser and do the same in JobControl.

Then put double-sided tape on the back of the TroGlass Mirror material. Position the graphic with the rectangles on it (the green border indicates the size of the paper), and after you laser process, you can peel off the adhesive film from the rectangles and affix the paper, so that you have the optimum distance between the rectangles on the paper.

Position the circle with the engraving on a free spot where there is no adhesive tape on the material.

The parameters may vary depending on the laser machine used and available laser power.

We engraved the TroGlass Mirror material with the fiber laser source because it engraves only the mirror layer rather than the TroGlass itself. This gives you the best engraving result from this material.

Step 9:

Take the large circle of MDF with Ø194mm and insert the ball bearing into the middle recess, then glue the smaller circle (Ø160mm) made of MDF to the underside. This serves as a pedestal and gives the display a floating effect.

Assemble the TroGlass cube and glue the smallest circle of MDF (Ø20,2mm) onto the X-marked center point with acrylic glue. After the glue has dried, insert the cube into the ball bearing. The 8mm-thick TroGlass disc is provided with a double-sided adhesive tape around the edge.

Stick the disc onto the cube using adhesive dots or acrylic glue. Again, an X marks the center points so that you can centrally position it.

Attach the paper strip with the TroGlass Mirror parts. To do this, turn the display made up to now on the head, remove the adhesive strip from the edge of the window, and carefully glue the paper strip. Make sure that the beginning and end of the strip are at the open part of the cube. Do not stick the strip in place if you want to illuminate the display so that you can still reach inside the display, but you can create a closing mechanism through a magnetic solution.

Finally, glue the cover plate made of TroGlass Mirror onto the transparent pane using adhesive dots.

Now your eye-catching display is complete.

Inspiration:

- The display looks great on your sales counter to showcase exceptional or special merchandise. Your customers can use it to display products for different events.

- As a simplified version, you can also build the display without lighting and without ball bearings.

- With a few technical adaptations, you can also use the display upside down as a funky lamp.