WYSIWYG (pronounced “wizzywig”) is the acronym for What You See Is What You Get. In graphic technology terms, this means that what you see on the monitor resembles as close as possible to what your printer will produce, no matter the type of printer, substrate, or ink-set. WYSIWYG is a standard to strive for to assure color quality and consistency.

Color management

Color management (CM) is a process that ensures colors are consistently represented across different devices and mediums. Whether an image is displayed on screen or printed to a substrate, color consistency is important to assure predictable results.

CM is frequently ignored by the novice print technician. When an image is printed, simply choosing to let the printer manage color and relinquishing control of the final output to a single device will not usually yield satisfactory results. The disparity can be observed by comparing the unmanaged print to the image on the monitor. Disappointing at best!

The basics

Because different devices interpret and reproduce colors in their own unique ways, CM’s purpose is to standardize and control variations so that colors look the same no matter where they are displayed or printed.

The idea of synchronizing color output on all devices in the digital workflow can be daunting. The hard reality is that a color-managed environment is essential for consistent quality output, but fortunately, though technical, CM is not that complicated. The basic concept is that color varies between different capture devices such as digital cameras and scanners, and between different output devices such as monitors and color printers. Managing color is the process of finding a common color workspace for all the devices in the workflow to ensure that colors appear and print on each device as similarly as possible (Fig. 1).

Color difference

The same colors appear differently from each device even though the same data is being processed. Input devices such as scanners and digital cameras, and output devices such as monitors, inkjet and color laser printers, color copiers, and web and offset presses have individual color capabilities. CM helps to resolve these color inconsistencies and match color on all the devices in the workflow. CM does not guarantee identical color reproduction. It does, however, enable significantly more control over the color produced by each device.

Color profiles

Every device that captures, displays, or prints color, uses a color profile. This profile defines the range of colors (the color gamut) that a device can produce. For example, the color profile for a digital camera will describe what colors the camera is capable of capturing, while a printer profile will describe how it reproduces those colors on paper with ink.

The International Color Consortium (ICC) developed a standard for color profiles known as ICC profiles. These profiles help ensure that colors are consistent across different devices and platforms by translating colors from one device’s color space to another’s. An ICC profile contains data about a device’s color characteristics and how it interprets and displays or prints colors.

Color spaces

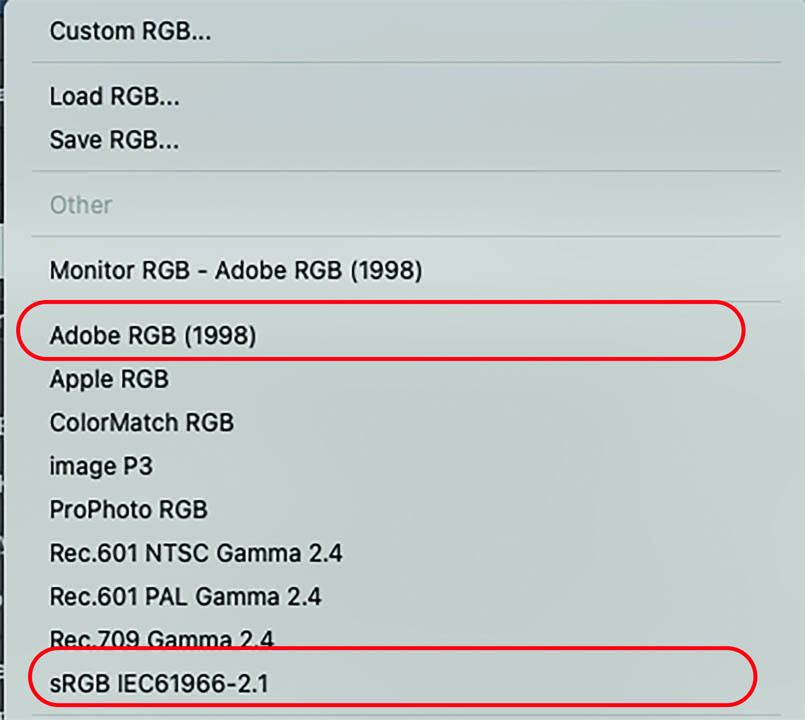

A color space is a specific range of colors that a device can potentially display or software can utilize. For example, sRGB is a standard color space commonly used for web images, while Adobe RGB has a broader color gamut and is often used for professional CMYK, offset lithography print work (Fig. 2). These two-color spaces are industry standards for outcomes, but there are dozens more available for specific devices. Custom profiles can also be created with special equipment.

First steps

The first step in the CM process is to calibrate the monitor so that the on-screen image looks it’s best. The quick and cheap option is to choose a profile from the monitor settings that will adjust the display’s colors to the desired profile (Fig. 3).

Colorimeter

A better, more accurate solution is to use a tristimulus colorimeter that measures the temperature of the light displayed on screen. The colorimeter attaches to the screen and measures the color temperature, gamma, and white point of the display. The calibration software sequentially generates screen images of several colors and tonalities in red, green, blue, gray, black, and white. The colorimeter device (Fig. 4) analyzes and records the data to the software. Analyzing the projected swatches, the software writes a profile based on the color temperatures it records and saves it to the appropriate system folder.

Screen to print matching

Matching a print to a monitor display is a bit more extensive process. After the monitor is calibrated, specific profiles for the printer and substrate can be made to assure color accuracy. A color chart (provided by the calibration software) is printed on the target printer and on the substrate that is being profiled. (Fig. 5). The color chart consists of multiple swatches of color.

The chart is scanned with a spectrophotometer that records the wavelength of each swatch. (FYI, colorimeter and spectrophotometer devices are often combined in the same device.) The spectrophotometer software analyzes the data and writes an ICC color profile based on the characteristics of the ink-set and the substrate and places it into the Color folder in Windows or ColorSync folder in Mac.

Color settings

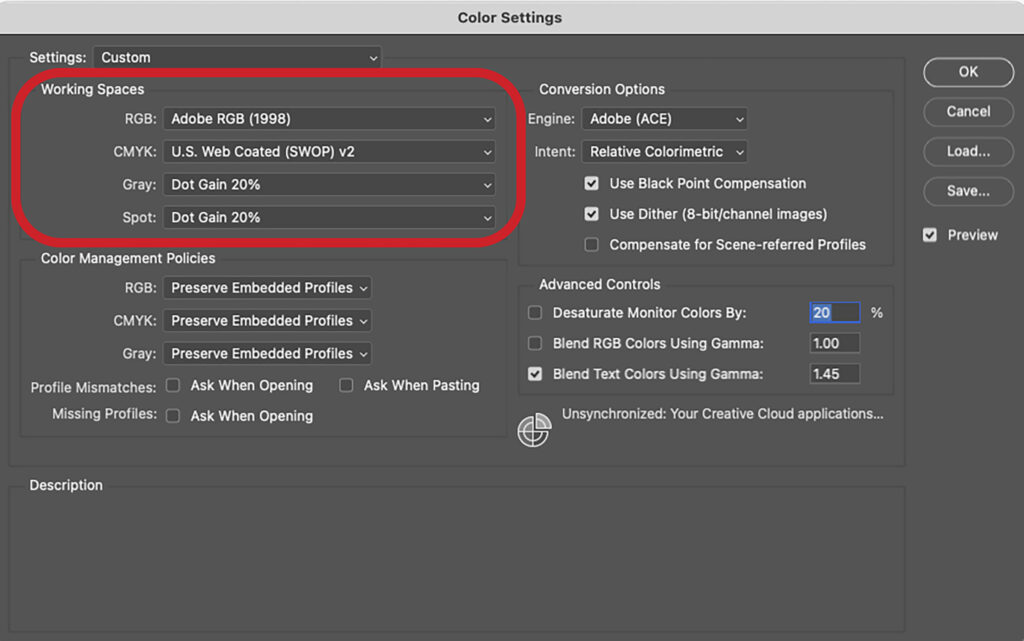

The profile is accessed in Photoshop’s Color Settings dialog box (Fig. 6). The Settings menu lists a set of profiles that are primarily for conversion to color separations for offset lithography including North American, European, and Asian pre-press working spaces. The Working Spaces field is where the RGB menu is and where profiles are selected and loaded for RGB, laser, inkjet, or large-format printers.

Canned profiles

Many printer manufacturers include premade profiles with their driver software, or they can be downloaded from the web. They are automatically loaded and accessed from the Color Settings menu when the driver is installed. These profiles were made for specific printing environments. They change the RGB values of the image to match the color capabilities of the ink-set and the reflective qualities of the substrate to produce an on-screen image that mimics the potential gamut of the printer’s capabilities. Profiles for many common substrates are available from most major printer manufacturers.

Color shifts

There is likely to be significant color variation when the ICC profile is assigned. Sometimes the image will become darker or contain a cyan or reddish cast, or the contrast will change. With the image visible on screen, make color modifications to improve its appearance. Color adjustment layers such as Levels, Curves Hue/Saturation, Vibrance, etc. can modify the image until it looks perfect. As the image is adjusted, the profile displays colors that are within the printer’s color gamut. When the image is printed, the print appears as close to the on-screen image as possible.

Updates

Color management has been a part of the digital workflow since 1996 when Adobe introduced it to version six of Photoshop. At the time, graphics professionals were perplexed as to why it was necessary. Since then, however, it has become an integral part of the graphics workflow as designers, digital artists, and print professionals realized the importance of having a color-synchronized workflow. Naturally, over the years, CM has evolved to become more sophisticated and to embrace current trends in technology. Here are a few of the recent changes and improvements.

Expanded color gamut & high dynamic range (HDR)

Newer devices and standards, like the DCI-P3 color space and Adobe RGB, offer a wider range of colors compared to older standards like sRGB. This is particularly relevant for high-end monitors and digital cinema.

HDR technology enhances the range of colors and contrasts that can be displayed. HDR standards like HDR10, Dolby Vision, and hybrid log-gamma (HLG) are becoming more common, requiring updates to color management workflows to handle the expanded color gamut and increased brightness range.

Calibration

New calibration equipment and software offer more automated and precise calibration processes, making it easier to maintain color accuracy over time. These features automatically adjust settings and provide detailed reports. Devices are increasingly being calibrated for specific media types, such as different types of paper or screen technologies, enhancing the accuracy of color reproduction across various outputs.

Improved color profiles

The ICC continues to refine and expand its standards. New profiles and updates help improve color consistency across emerging technologies and devices.

Device link technologies enable more precise color management by defining how colors are converted between specific devices.

Cloud-based color management

Some solutions are moving to the cloud, offering collaborative color management tools that enable teams to share and maintain consistent color profiles across different locations and devices.

AI & machine learning

AI-driven tools are being integrated into the CM workflow to predict and correct color discrepancies more effectively, based on learned patterns and data.

Enhanced printer & display technologies

Advances in printing and display technologies, including new ink formulations and RGB monitor configurations require updated color management practices to ensure accurate color reproduction.

Sustainability & environmental considerations

The move toward more sustainable printing practices involves using eco-friendly inks and papers that can affect color management processes. New profiles and calibration techniques are continually being developed to address these materials and maintain color accuracy.

Overall, the advancements aim to improve the precision, ease of use, and adaptability of CM systems to meet the demands of modern technology and diverse applications.

Predictable color

CM is essential to producing consistently predictable color whether on image capture devices such as scanners and digital cameras or output devices like monitors and printers. Color standards differ for each brand of camera, scanner, and monitor. Profiles for these devices should be assigned that are consistent with the desired output.

Since ink-sets are proprietary and substrates absorb ink and produce color differently, a distinct profiles for each printer and each substrate that is part of the workflow should be created. Predictable color means less waste in time and materials. If consistent color is important, the initial expense of a calibration system is well worth the money because it eliminates the extra effort and materials required to reprint unsatisfactory images.