A wrapped vehicle is not just a rolling billboard for your customer. It’s also a mobile advertisement for the quality of your wraps. It behooves the customer to protect and maintain their vehicle so the wrap investment is maximized, which in turn protects your work as well.

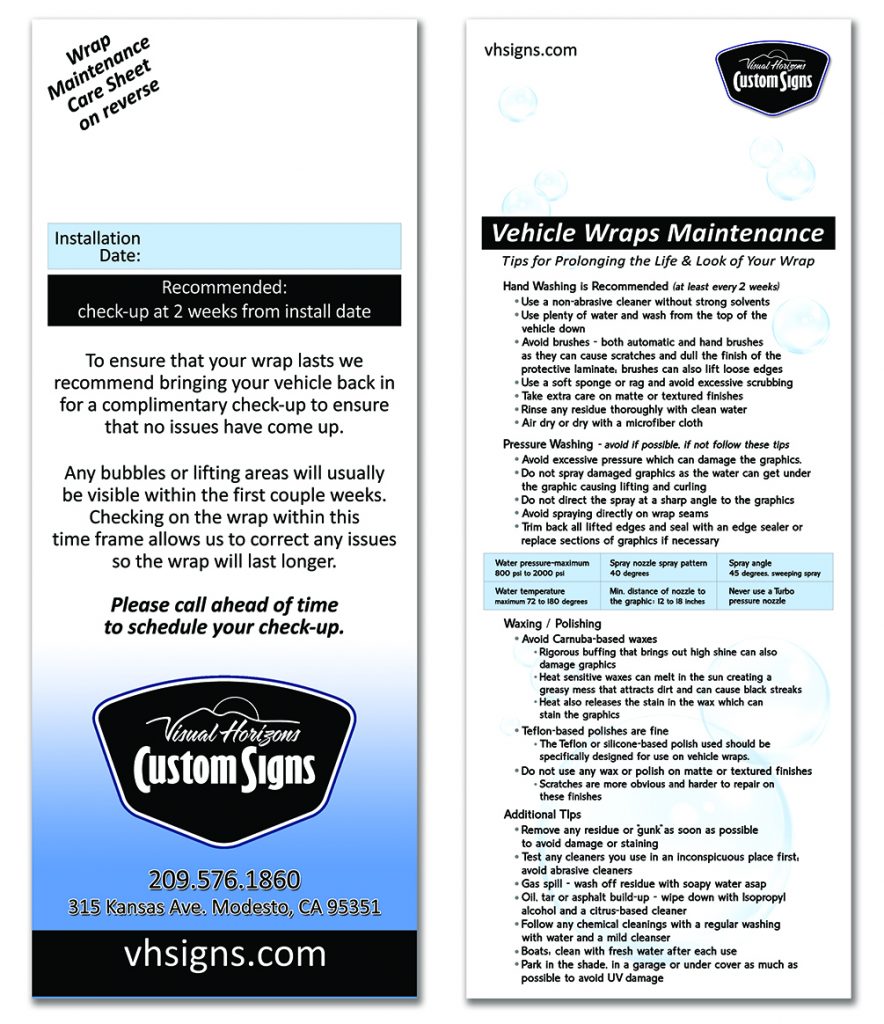

It’s not uncommon that a customer will ask about how to maintain their wrap when they pick up their completed vehicle. You should have clear answers for them, and it also makes sense to have a helpful handout that they can take with them. This gives them something to reference and makes your counter time more efficient.

While we recommend the customer brings their vehicle in about two weeks after the wrap for a check-up, where we’re looking for bubbles or lifting, washing is something that is an ongoing maintenance issue. Proper washing will avoid damage to the surface of the wrap.

Washing

How to wash the wrapped vehicle is typically the first question we get asked. Dirt and other contaminants that remain on the vehicle can cause damage to the surface of the graphics, and can also be more difficult to remove. Any residue should be removed as soon as possible, with routine washing every two weeks.

After as much dirt is rinsed off as possible with water, a non-abrasive detergent and a clean cloth or sponge should be used to wash down the vehicle. The vehicle should be rinsed with clean water and excess water removed with a squeegee and clean microfiber towel to reduce water spotting.

Bird droppings, tree sap, and bug splatters often dry onto the surface before they can be removed. To avoid damaging the surface of the wrap it’s best to soften the contaminant by soaking it with hot, soapy water, before rinsing and drying.

Wraps often cover right over fuel doors and are then subject to fuel spills. Advise your customer to wipe off any spilled fuel immediately, then wash, rinse, and dry the surface.

Car wash

We tell our customers that hand washing is the best option because you have more control over abrasion and the chemicals that will get on the vehicle. Wrapped vehicles can still be run through car washes though when hand washing isn’t a feasible option.

According to 3M’s vehicle care sheet, they mention that vinyl wraps can be run through car washes, but “touchless car washes are the best for graphic care.” They go on to further point out that “brush car washes may cause dulling/scratching/lifting edge of the graphics.”

Pressure washing

Some of our fleet accounts bring in professionals to pressure wash their fleets on a routine basis; especially the big box trucks and over-sized trailers. A large fleet and/or large vehicle isn’t easy to hand wash so often pressure washing is the best bet.

Pressure washing can take paint off a vehicle if it’s not done right, which means it can easily lift and remove wrapped panels as well. Because there’s technical information and specific numbers involved, we recommend including this information on your handout for the customer to reference.

Here’s some of the points we’ve included in our handout:

- Avoid excessive pressure

- Do not spray damaged graphics as water can get under the graphic causing lifting and curling

- Do not direct the spray at a sharp angle to the graphics

- Avoid spraying directly on wrap seams

- Trim back all lifted edges and seal with an edge sealer or replace sections of graphics if necessary

- Max. water pressure: 800 psi to 2000 psi

- Spray nozzle pattern: 40 degrees

- Spray angle: 45 degrees, sweeping spray

- Water temperature: max. 72 to 180 degrees

- The minimum distance of the nozzle to the graphic: 12–18″

- Never use a turbo pressure nozzle

Wrap care products

While warm, soapy water and clean towels are a great way to keep a wrapped vehicle clean, there are other products available to help clean and maintain wraps. Vinyl manufacturers may have their own product line they recommend, in addition to other products available on the market. Be sure the products used do not contain petroleum distillates.

While some of these products may work fine on gloss vinyl, they may not be recommended on matte, textured, or chrome vinyl. Be sure you reference product bulletins and test cleaners in an inconspicuous location before using.

Waxes and polishes

Beyond the cleaners and waxes mentioned above, there are a few key specifics that you should mention to your customers.

- Avoid Carnauba-based waxes – the rigorous buffing that brings out a high shine can also damage graphics. These heat-sensitive waxes can also melt in the sun and create a greasy mess that attracts dirt and can cause black streaks. Heat also releases the stain in the wax which can stain the graphics.

- Teflon-based polishes are fine – choose a polish that is specifically designed for use on vehicle wraps.

- Do not use any wax or polish on matte or textured finishes unless it is specifically designed for those surfaces.