As a sign shop that specializes in vehicle wraps and fleet graphics, paint protection films (PPF) have been a consideration for our shop for a while, but not a service we’ve yet jumped into. The newer generation of PPF is worth investigating, but we still may not choose to add it to our services, and I’ll tell you why.

What is PPF?

So, let’s start with the basics. We’ll discuss colored PPF in a minute, but for now we’ll focus on clear films.

Paint protection films are clear urethane films that protect paint and offer UV resistance. They’re typically applied to the hood, bumper, mirrors, and other high-impact areas. They help protect a vehicle’s paint and help with its resale value.

The films have evolved over the years as the clarity of the film has improved, along with the ease of installing. Clear films retain the original paint color of the vehicle and look nearly invisible when installed correctly.

It’s a thin, stretchable film that conforms to the contours of the vehicle much like color change and printable wrap films, but PPF is thicker and more durable. PPF also has a longer warranty at five to 10 years versus color-change wrap vinyl having a warranty up to three years. Higher-quality PPF tends to have a longer warranty.

Elongation at break

PPF also has a higher stretch percentage, often referred to as elongation at break. A premium color-change wrap vinyl will have an elongation at break percentage of up to 200%. This means the film can be stretched up to two times its length before breaking or tearing. It doesn’t mean you’ll routinely stretch it this much during the install, but you can in areas when necessary.

For PPF, the elongation at break percentage can be well over 300%, which means the film can be stretched over three times its original length. So why is this higher stretch rate important?

Since PPF is primarily used to protect the surface of the vehicle, the higher stretch percentage allows the film to absorb and distribute the force from debris or rocks hitting the vehicle surface. This higher percentage also helps with the overall durability of the film and its resistance to tearing.

During installation, the increased stretch helps the film to conform to curves and contours. This helps you get a smoother install without bubbles and wrinkles. For PPF with self-healing properties, the higher stretch rate allows it to be repaired with heat.

Color

Clear PPF was the only option for a long time. So, if you wanted to protect the surface of your vehicle, you added a clear PPF film and maintained the same vehicle color.

Later, if you wanted to change the color of your vehicle without painting, you could install a color-change wrap, but this doesn’t give you a lot of protection from the damage from rocks and debris. So, installers could then add PPF over the top of color-change wraps to offer both a change in color and the protection from the PPF film. Usually, installers did this in high-damage areas, but they could do it all over if desired.

Now, the PPF films come in colors. While there still aren’t as many color and texture options as a color-change wrap film, there are still an impressive number of colors, including camouflage print and color-shift options.

While colored PPF films are more expensive than clear PPF films and color-change films, they give users the best of both worlds. With the increase in car values and the awareness of these films, vehicle owners can now maintain their vehicle’s finish while playing with changing up the color.

Like color-change wraps versus commercial wraps, color PPF does come with a unique set of challenges. These challenges typically have to do with the differences in how the color films react during installation, to contamination, heat, and then their cost.

Considerations

Adding PPF to a vehicle is a premium service. It’s not something every vehicle owner is going to ask for, but a customer who has a nicer vehicle that they want to protect is likely to be willing to pay for this service. If your shop already specializes in vehicle wraps or other vehicle-enhancing services, this might be a good area to get into as an upsell to your existing services.

As with any new service, training and skills are required to create a quality product efficiently. Even though I’ve wrapped for years and years, I wouldn’t jump into a PPF project on a customer’s vehicle without a lot of practice and training ahead of time.

There are certified training opportunities out there. Just like with commercial wraps and color-change wrapping, I highly recommend taking a hands-on training course before offering PPF as a service.

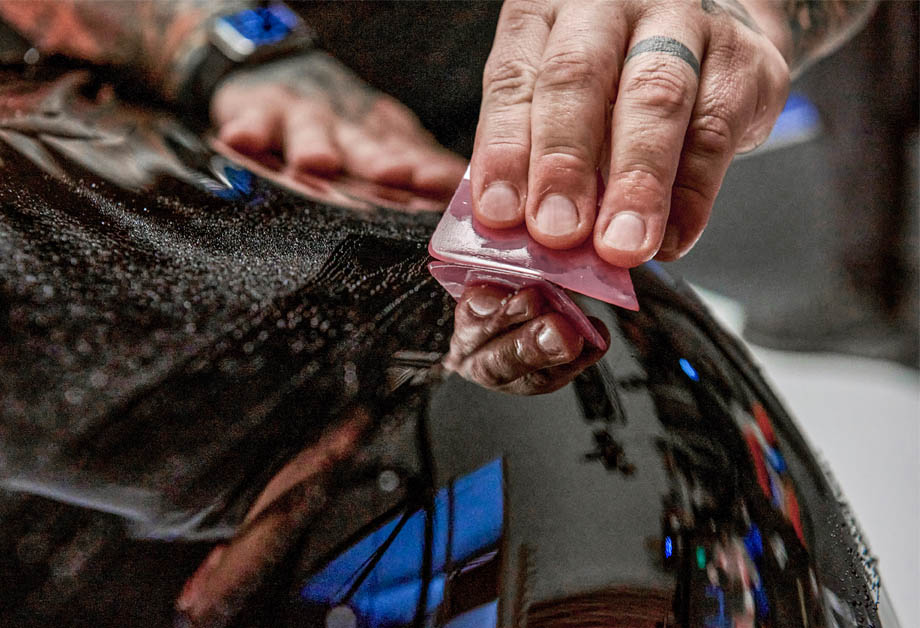

In researching the process of installing PPF, I’ve learned a lot about vehicle prep, slip solution, tack solution, the differences in squeegee technique, and edge finishing before trimming. While there are a lot of similarities to wrap installation, the differences in installing PPF are where skills, training, and experience are key.

Why not?

So, back to my initial statement as to why we may not choose to add PPF to our list of services. Our shop is simply not set up for it. Like with color-change wraps, I know the limitations of our shop.

About 20 years ago, we found a commercial shop space that is close to downtown, near the freeway, with high visibility to traffic, and considered an industrial area, so we pay much less for the amount of square footage we have. But that means we have to deal with a space that is not as dust and climate controlled as I would love to have.

Since we specialize in fleet graphics and commercial wraps, our vehicles move through the shop much faster. Commercial wraps are all about the advertising, while a color-change wrap and a PPF install are about the look and how it enhances the vehicle’s finish.

While we do an excellent job installing our commercial wraps, our customers are not scrutinizing the vehicle for tiny flaws like they would on a color-change wrap or PPF install. There’s simply a different approach to the speed and install techniques of commercial wraps over color-change, and the cost of each reflects this.

In our industrial shop, it’s harder for us to maintain the environment needed to ensure a flawless install if we worked with PPF. For this reason, we’ll probably choose not to offer the service because I know we can’t offer the highest quality finish in the most efficient manner. It’s all about knowing our limitations.

Overall, I think PPF is a great service to offer your customers if you’re interested in getting the training necessary to offer a quality product. But, you need to consider your customer base, or the clientele you’re wanting to attract, and you need to consider your shop space and how this might affect the quality of the installation.