Fearlessly Moving Forward: GeckoWraps Adds Options to Beat Pandemic

GeckoWraps used the last year to invest in new equipment, so it can say "yes" to any job

In 2006, GeckoWraps was formed in the back of a small shop that we shared with our other businesses. The 20′ X 20′ makeshift print room was tightly packed with four desks, a cuttable, a Mutoh printer, a Graphtec plotter, and the laminator posted in the install bay. Picture it: cold concrete walls to the back and front of us, and pallet racking with coroplast glued on the uprights to make the walls that separated the installation bay from the print and design room. This meager beginning is something that might sound very familiar to many start-up wrappers. We came in guns blazing with minimal equipment, but it was enough to produce a quality wrap, and that’s all we needed at the time.

As time moved forward, we progressed to sell anything we could get wholesale. Basically, we never said no to a project, and that in itself made us successful. We found vendors for everything.

We had the “router” guy, the “flatbed printer guy,” and the “grand-format Guy,” creating a resource to offer more for our clients. Just because I didn’t have the machines to do the job didn’t mean I couldn’t find a way to get the products at a wholesale rate and resell them for a margin. My favorite quote from my wife, Nicole Lloyd, is, “Nobody ever made a dollar from saying no to a job.” Saying yes to jobs forces you to adapt and overcome and help you with the mental fortitude to complete it and make some money. And one day, we could get our own equipment and expand the capabilities of our offerings as a major goal.

Make a goal and follow-through

I often look to the future of my business and think of what we can do better as a company, how can we serve our customers better, and what products and services we can add? This evolves into making goals and figuring out what steps we need to take to get to where we want to go. I look at this as an area of opportunity. Evaluate all the areas that you see as potential opportunities and start ranking them. The next step is to create an avenue of approach to figure out ways to make your area of opportunity happen.

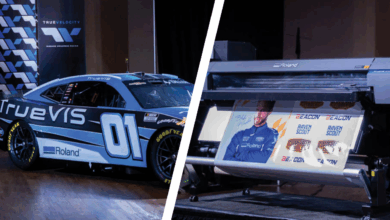

Flash forward to the end of 2019 and the beginning of 2020, which started extremely promising. We had evaluated some potential opportunities and did our market research for our area in Las Vegas. We decided to make some equipment purchases and expand our capabilities to fulfill an area of opportunity that was new for us: trade show fabric prints for silicone edge graphics (SEG).

At that time, trade shows were in such high demand it seemed like the perfect opportunity to get into the market. In January 2020, we pulled the trigger and purchased our HP Latex 3500 grand-format printer and all the specialty sewing equipment we needed to move forward in handling the production of SEG.

The excitement was palpable, and we began to layout our shop, setting up stations and getting ready for what seemed like a sure thing. We took delivery of our machine on Feb. 23, 2020, got it all set up, and then three weeks later, COVID stopped us dead in our tracks. Everything got canceled. No trade shows, no events, casinos closed, bars and restaurants closed down, and Vegas became a ghost town overnight.

We had just taken on a great asset, and now the pandemic took all our opportunities and put a giant pause on everything. The printer seemed like it was a giant paperweight sitting in the shop in all its glory. At this time, we had to reevaluate our entire situation, just like the entire world did, and we had to figure out how to keep the doors open and think how we could come out of this pandemic in a better position.

Over the course of the next 11 months, we scraped by trying to do our part as an essential business and keeping a goal in mind to keep trying to expand capabilities. Giving up was not an option. We decided to double down. I guess my go-big-or-go-home mentality took over and the “build it, and they will come” mantra took control. We started looking at more equipment that would complement us and give us an edge, and for every area of opportunity, we created an avenue of approach.

We had large-format printers, a grand-format printer, a Klieveric rotary heat press for fabrics, and sewing was all set up, so the next obvious purchase was to gain entry into the flatbed printer market. The flatbed printer market is intriguing in many ways. A few examples would be that a great UV flatbed can print on pretty much anything up to 2″ thick and, in some cases, up to 4″. That really opens the doors to do a variety of sign work. With a matching cutter/router table, you really get to see how impressive it is to produce interior signs, fancy multi-layered acrylic prints, and art. Plus, tossing in 4′ X 8′ sheets of coroplast, foam board or PVC, is way easier than printing it on wrap vinyl and mounting it to a sheet. That alone was the kicker for us to keep moving forward.

Keeping a positive mindset and focusing on goals kept us motivated to keep trying, regardless of the pandemic. There are many resources for finding equipment. We found a used printer broker that became a great source in our search for a flatbed printer while keeping an eye out for an efficient router/cutter system that was gentle enough for cutting fabric and aggressive enough for cutting thin aluminum. The ability to print and cut flexible and rigid material would give us an added edge. With a plethora of equipment, we have all the capabilities to provide many products and services.

Create simplicity with technology

One thing the pandemic has done is push our limits with how interactions with everyday life have changed. It’s affected everything dealing with shopping and pushed a switch to buying online and eliminating the need to conduct business face to face. Social distancing has changed the way we work and the way we buy virtually everything. With this in mind, we began to look toward the future.

Now that we have our equipment, how can we find a way for us to weather this current economic condition to address the inevitable of purchasing vehicle wraps, prints, and signs online? Eventually, our industry will be overrun with online transactions — the writing’s on the wall. Online is the future; brick and mortar has changed, and we are now all facing it. So, for us, we came up with JustPrintSigns.com for wholesale large-format, grand-format, and flatbed printing. The goal was to create an easy-to-use platform for ordering signs online.

Although all this sounds great, I don’t want to give you all sunshine and rainbows. Let’s talk about some of the drawbacks that come with online buying.

To make customers online feel comfortable with making a sign or wrap purchase, we needed to find a way to make the transaction easy. For me, the most anxious thing about buying something online is the complexity of the shopping cart. If it’s difficult, then nobody will go through that process. The whole “paralysis by analysis” thing can happen if the process is too overbearing.

Easy ordering, quality products promptly is what we all want. Providing a central place for all the technical data and specs of the product you’re buying, as well as tips and tricks and warranty information, really gives someone those warm fuzzy feelings just like they would get from buying in person.

Keep in mind, customer service will need to grow equally to the curve of your business to handle any extra offerings you have, whether you’re buying wholesale items or manufacturing and shipping. You must always keep your customer service on point. As we have grown our business, we will continue to implement many elements of customer service, quality, pricing and increase the timeliness of our final products.