I recently missed a week of work because I came down with COVID-19. Being out reminded me that over the years, we’ve built a good system because, despite being out of the shop, my absence didn’t create a huge hiccup. With cloud access to files and emails, I could still check my messages from home and forward important ones to someone else in the shop to ensure that customers weren’t overlooked.

Because our employees are cross-trained, we always have a couple of people who can handle the front counter, phones, graphic design, production, and installation, even if one or two people are out of the office. This is even though we’re a very small and busy shop.

Having a workflow system in place and having an attitude of efficiency means our shop runs smoothly with a small crew despite our workload. Good efficiency is one of the most important areas to master in your shop because it leads to higher profits. Maximizing workflow hours and minimizing waste means more money in your pocket.

Attitude

In some ways, our efficiency is a matter of attitude or habits. Quick responses to emails are a good example. Instead of emails piling up or being overlooked for days, we try to respond the same day we receive an inquiry. Then, we sort the emails and use them as part of our to-do list.

This doesn’t mean we’re always able to research and answer a question or figure out an estimate they’re requesting the same day, but it means we let them know we received their email and will get back to them as soon as possible. You’d be surprised how much of a difference it makes when you acknowledge their message.

Along with quick responses to emails, we also try to respond quickly with estimates. On some estimates, the customer may take some time to consider, especially if it’s a bigger job, but responding quickly while their interest is piqued will often expedite the conversion from estimate to invoice.

For smaller projects, a quick estimate often results in an approved job that much quicker. People often quote around, so if you get your estimate over quickly, you’ll often earn the job over someone who takes longer to get back to them. People are used to instant gratification, and this translates to our business as well.

System

A big part of our shop efficiency is because of the workflow system we have in place. Our system covers a job from the front counter, through every step in design, production, and installation, if needed.

A few terms used to define the word “system” help clarify the goal: “a set of things working together,” and an “organized framework or method.” Having a set procedure for how you work through a wrap estimate, how you help a customer at the counter, or how the job is tracked through production keeps your shop consistent, efficient, and profitable.

I’ve written past articles that explain our workflow system if you would like more detailed information. To summarize, we have tools and work order sheets we use at the front counter to aid us in gathering information from the customer, to help them choose colors, or to decide on wrap coverage.

Once we have an order, the job moves into the design stage, then approval, output, onto production, and then either it’s shelved for pick up or goes to a separate shelving area for graphics that need to be installed. As the job moves through each of these phases, we update the job within our online job tracking system so that at any time, from any desk, you can look up a job and see where it is in the process.

When the job moves to production and then to installation, it’s written on a dry-erase board as well to help production keep track of jobs in the queue. We also make notes about substrate sizes, due dates, installs scheduled, and any other info they may want at a glance.

Details

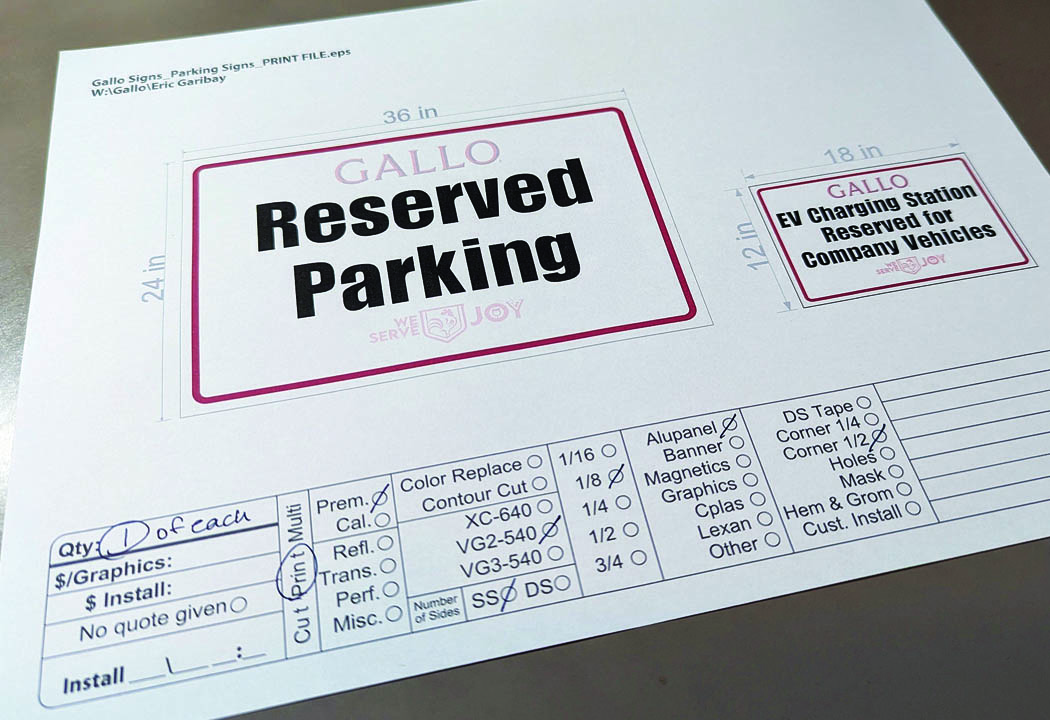

We’ve created a custom template that we apply to approved jobs. We print out this template in color, including an image of the job and any sizing details or information on the setup print files. The template has preprinted boxes we can quickly mark at the bottom. Here, we note which printer should output it (for consistency with previous jobs) and the type of media it should be printed on. If it’s a sign, we can mark the type of substrate, including thickness, and if it’s a single or double-sided sign. There are also boxes for rounded corners, adding holes, and making notations.

Filling out the template completely is important. Not only does it remind you to fill out all the information for others in production, but having this information on file for future orders is important to maintain consistency.

We have one or two people who typically oversee the output of jobs as they come into production. At any time, we can quickly pull the template to see the marked media type and can then group our prints by media type. This process saves time by reducing the need to load and unload media, maximizing the use of media by grouping prints, and increasing laminating efficiency through printing jobs together.

Tips

Several small things around the shop help us to be efficient. Some are tools and some are procedures, but each item makes us more efficient. Here are just a few of those things:

Substrate rack: We had a dozen 4′ X 8′ sheets of aluminum composite come in today and we simply rolled our rack from beside the panel saw to the back roll-up door, helped the delivery driver offload them onto the rack, and rolled it back into place. We’re not wasting time moving sheets around and we don’t risk having them get damaged by falling over.

Grouping cuts: We have a panel saw we use for some substrates and larger panels and we also have a stomp shear we use for our smaller aluminum composite signs. Since we primarily use aluminum composite (over wood, PVC, or aluminum substrates) we often have multiple jobs going that require cut substrates. We go through our jobs and write down all the different sizes and quantities needed, then cut them all at the same time. This helps us maximize our sheets and saves time by not going back and forth to cut substrates.

Customer keys: We cut a small piece of aluminum composite material, overlaid with dry-erase laminate, and attached a small board with hooks on it. We attached this to the wall in a central location. When a customer drops off a vehicle, we put their keys on a hook and write their name above the hook, along with a contact number if needed. Below this, heavy-duty paper clips are screwed to the wall and the customer’s paperwork hangs here after installation, so when they pick up the vehicle, the keys and paperwork are all in one place.

Pre-mix bottles: We use a concentrated ZEP window cleaner that is mixed with water to make up our spray bottles. We also get gallons of isopropyl alcohol that we mix with water to make a 70/30 solution. On previously emptied bottles of both the cleaner and the alcohol, we’ve marked lines to show how much alcohol and how much cleaner is needed in the bottle. Then we add water to the next line. This makes it easy to pre-mix needed solutions, fill our spray bottles, and then have backup jugs when needed.