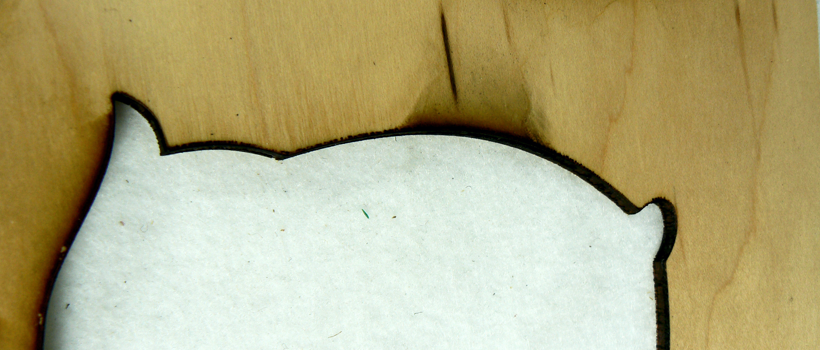

I generally try not to laser raw or stained wood that does not have several good coats of finish on it because, as lasering turns wood into a heavy and sticky gas that falls onto the wood, it lays there until you clean it off. On raw wood, this byproduct gets into the fiber and is almost impossible to wipe off (see image below). If you use a chemical, it then colors the wood a different color than the surrounding wood and looks horrible. Finished wood with a clear coating provides a hard layer that the gunk can be easily wiped off without burying itself into the wood fibers. If it is finished with three or more coats, it comes off easily.

There is, however, one exception to this rule: when I know the project is not complete and the wood will be sanded after the lasering. Let the customer know that you will leave it for them to sand down and that only a light sanding is needed to remove the lasering residue.

My favorite product for cleaning wood is Liquid Gold. It cleans quickly and thoroughly and leaves a nice shiny finish. It removes shoe polish and some other products used as a wood color-fill.

I spray a little on a paper towel or cloth rather than on the wood product as it allows for better control. I shine up the entire product as customers appreciate getting their product nice and clean.

Learn more: What are the best types of wood for laser engraving?