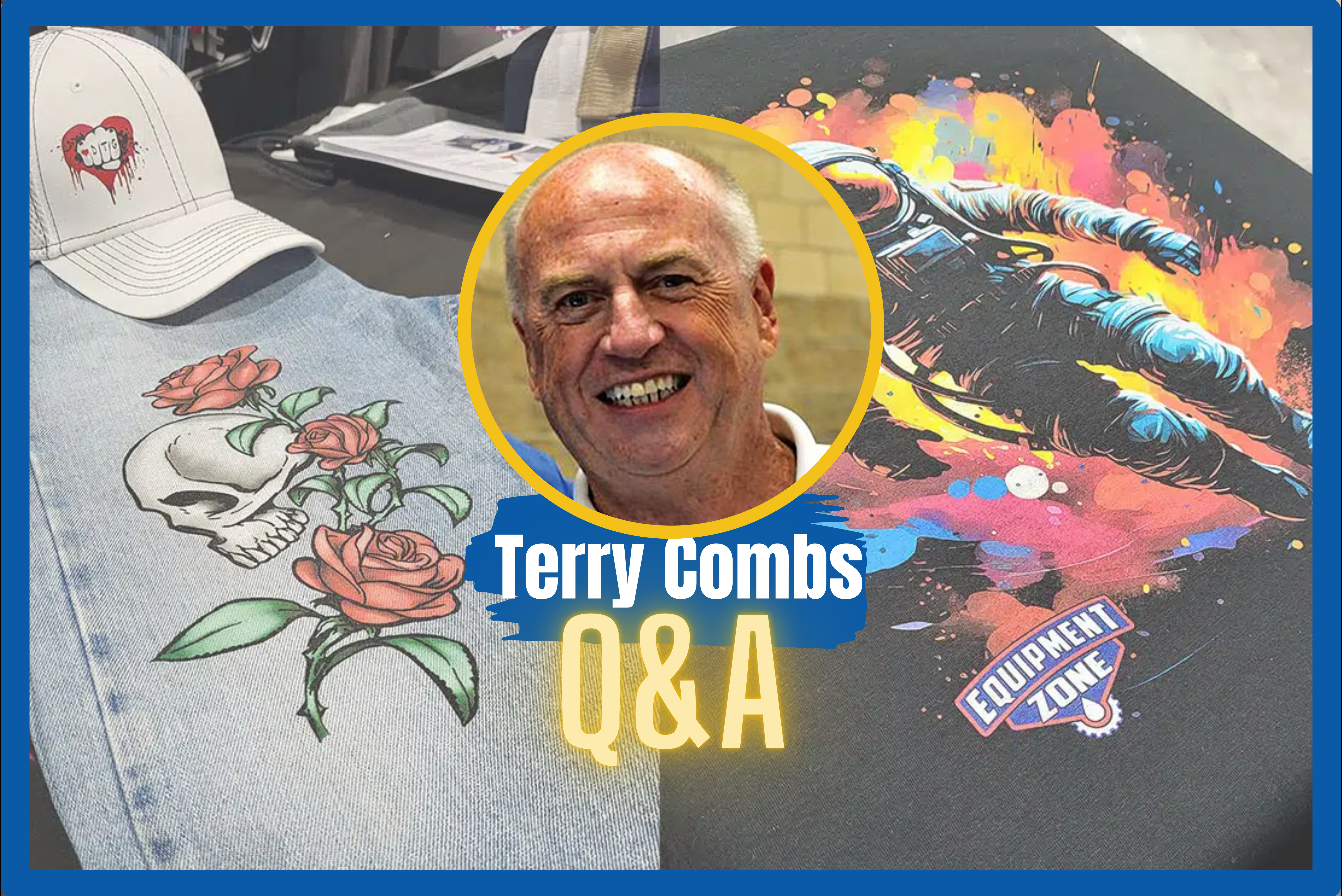

5 questions with Terry Combs

Terry Combs of the 2 Regular Guys podcast & Equipment Zone talked industry trends, technology & lessons learned.

1. Since it’s January, what do you think should be the top New Year’s resolutions for apparel decorators?

I was doing a consulting job once and after my report, the president of the company said, “We already know 80% of this.” My reply was, “And you paid me to come here to tell you that you haven’t done anything about it.” In 2025, be your own consultant and look at your business as if you’re an outsider. What things can you change to make your business better. Take one thing at a time. Don’t get ahead of yourself.

2. How did you get your start in the industry?

I often say, “Armed with my degree in journalism from Ohio University, I accidentally became a screen printer.” Starting a part-time screen-printing business right out of college, I fell in love with the industry and have been here ever since.

3. Equipment Zone distributes products in several business categories. How do you stay on top of industry trends?

As a company, we have a lot of interaction with decorators via webinars, in-house training events, trade shows, and literally talking to customers every day. Bottom line, we listen to what our customers and potential customers are saying.

4. Speaking of trends, DTF is here to stay, as they say. How can screen printers best leverage this technology in their shops?

First, I will say “Embrace it.” No, it does not feel like a screen print. Get over that, because the consumer has far less resistance to this technology than decorators do. For screen printers specifically, there is no dye migration with a DTF transfer. Dye migration is the bleeding of shirt color dyes into your inks when printing man-made materials. With the flood of these man-made fabrics into our marketplace, DTF is the perfect solution to a problem that drives screen printers crazy. Add to that, the trend in the industry over the past several years of more orders, but smaller per order quantities. And of course, the ability to print an unlimited number of colors with a quick and simple set up.

Building on 20 years of DTG decorating at this point, DTF printing has had a quick turnaround from concept to fully commercial production. Screen printers want to compare the speed of an auto to the speed of producing DTF transfers. The new Equipment Zone EZ JET 24 MAX has a production speed of 300 square feet per hour. DTF production has quickly gained ground on comparative production rates, with a fraction of the set up and tear down time of an automatic screen printing press.

5. What’s the most important lesson you’ve learned about the decoration and personalization industries as co-host of the 2 Regular Guys podcast (along with GRAPHICS PRO contributor Aaron Montgomery)?

In our 12 years podcasting every Friday, I’ve learned how passionate decorators and all participants in our industry are about what they do. Running a garment decorating business comes with the same highs and lows, frustrations, and achievements as running any other kind of business, but few endeavors give you the satisfaction of creativity that our industry does. That’s why so many people come into the industry and never leave.