Clients look to their screen printers and promotional products distributors for expertise, and I find sharing my knowledge with interested clients to be one of the most gratifying parts of my career. Sustainability in the apparel industry is a new and developing science, and as our friends in the CDC say, “The science is evolving.” What may have been the best advice from two years ago, may not always be the best advice today.

I have been in the sustainable apparel industry for nearly 15 years, and I preface the following with the acknowledgment that I have sold an awful lot of recycled polyester (RPET) garments in my time. When RPET became widely available around 2010 the story seemed almost too good to be true.

“We can take water bottles out of the ocean and make a fabric that is easy to produce, performs well, and is still affordable.”

And brands have been lining up to make more and more out of this feel-good fabric ever since. As the old saying goes, “What seems too good to be true, usually is.” What we now know about apparel made from RPET has caused me to make the decision to never sell it as an environmentally friendly option ever again.

RPET and microplastics

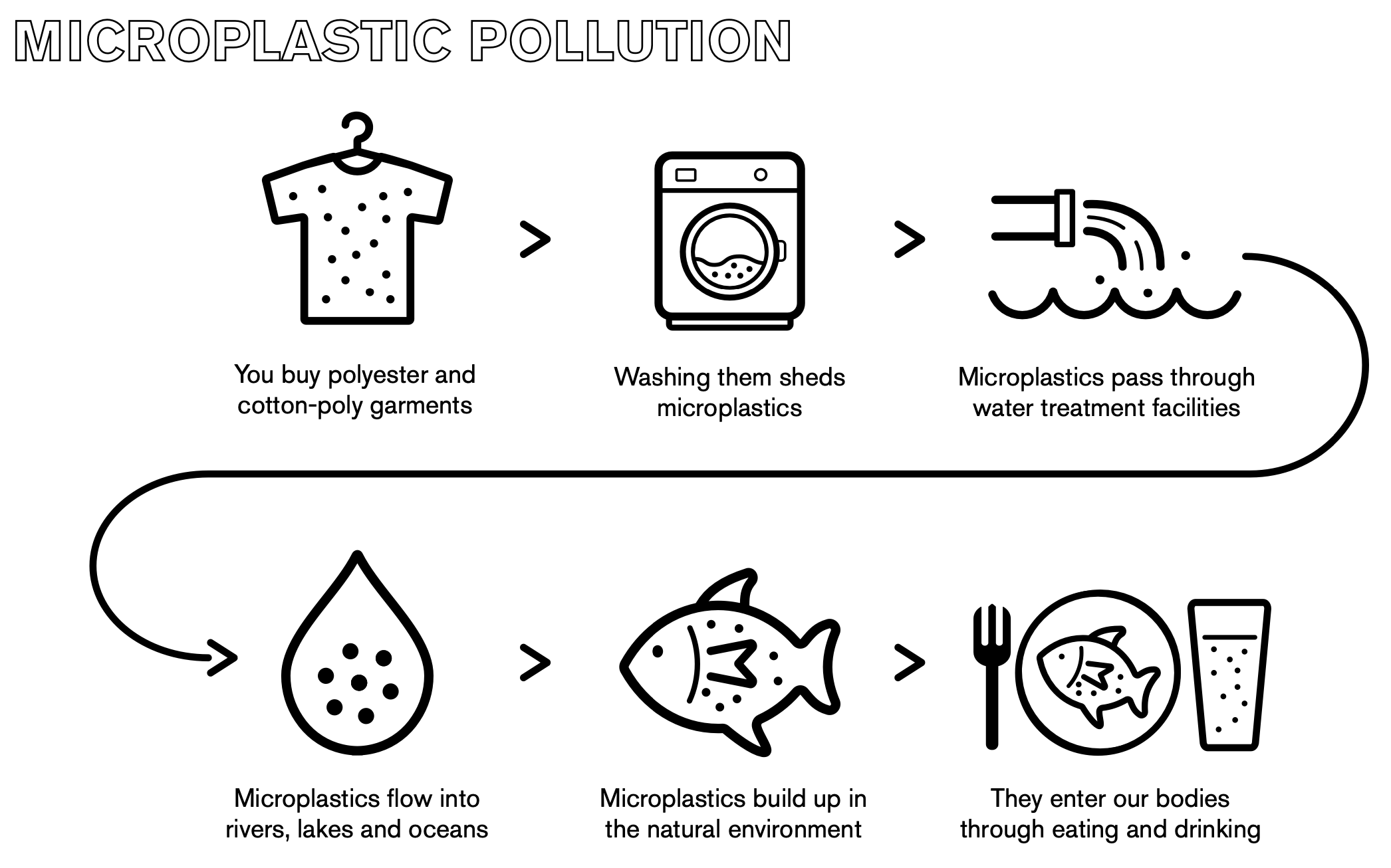

Rather than RPET being the sustainable silver bullet we had hoped for, it is actually a green-washed wolf in sheep’s clothing. The big problem is that RPET actively pollutes the environment through the shedding of microplastics. Microplastics are tiny fragments of plastic that are shed from your clothes through wear and tear — and in the wash — and are not biodegradable.

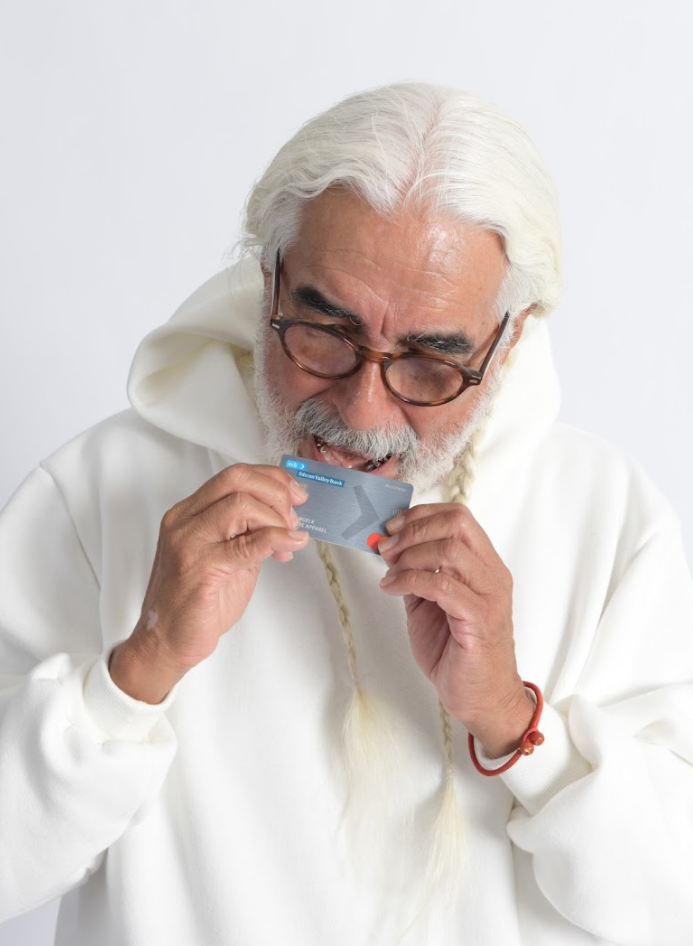

Microplastic pollution is now so pervasive in our environment that recently the state of California passed a bill to address this growing crisis. These specs of plastic have been found in the deepest depths of the oceans and on the top of the highest mountains, and even more concerning, inside our bodies and our children’s bodies. Each of us is now consuming a credit card’s worth of plastic (5 grams) every week. Along with car tires, synthetic apparel production and the washing of synthetic apparel are the primary sources of this pollution. And the science is now conclusive that RPET fabric, especially in the form of fleece, sheds microplastics at an even higher rate than virgin polyester.

The science is not yet conclusive on what microplastics do in our bodies, and while cotton or other natural materials also shed microfibers, they are not made of plastic and will naturally biodegrade. Until a biodegradable RPET is available, we would be better off avoiding RPET altogether.

What now?

The manufacturing of any item has its ecological cost, and the goal of this piece is not to convince those who do not care about the planet that they should start now (though they should). The point is to educate that growing part of the population that does care about our planet, (which probably includes you, if you are still reading) and those professionals in our industry who are called on to be subject matter experts, to look further into the realities of RPET. I call you to do a bit more research. Nobody likes homework, but if you are anything like me, unknowingly misleading your customers when they ask you for sustainable options is even worse.

Today, apparel can be affordably produced from 100% recycled cotton, and by every metric recycled cotton is the most sustainable material you can make a garment from. Many brands blend recycled cotton with RPET as this makes it cheaper and easier to knit. Unfortunately blending a garment with RPET not only makes it a microplastic polluting garment but also makes it non-biodegradable and non-recyclable. When your clients are looking for sustainable options, be the product knowledge expert they are looking for by warning them about the pollution caused by RPET and educating them about the benefits of recycled cotton.

For further reading on RPET and microplastics check out the following links:

- Domestic laundry and microfiber pollution: Exploring fiber shedding from consumer apparel textiles

- Me, My Clothes and the Ocean

- No Plastic in Nature: Assessing Plastic Ingestion from Nature to People

- A Detailed Review Study on Potential Effects of Microplastics and Additives of Concern on Human Health