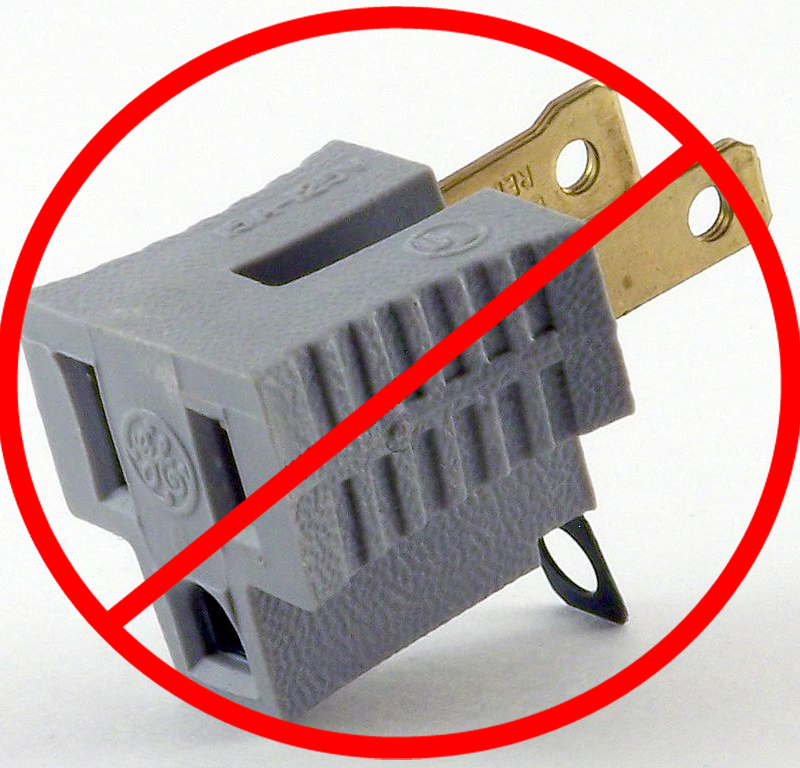

One of the most important considerations when getting started with white toner laser printers is your electrical power quality. Many people don’t realize how important good clean, steady power is. It’s best to plug these machines into a dedicated power line with at least a 15-amp fuse.

To understand the importance of power, it is crucial to know how laser printers work. A laser printer is a computer that is programmed using a page description language. Just like any computer, it needs the correct power to run.

A laser printer is a very high voltage, low amp, static charge generator. A bare corona wire carries a high voltage of 600 to 900 volts to apply an even charge over the surface of an organic photoconductive coating on a grounded steel bar.

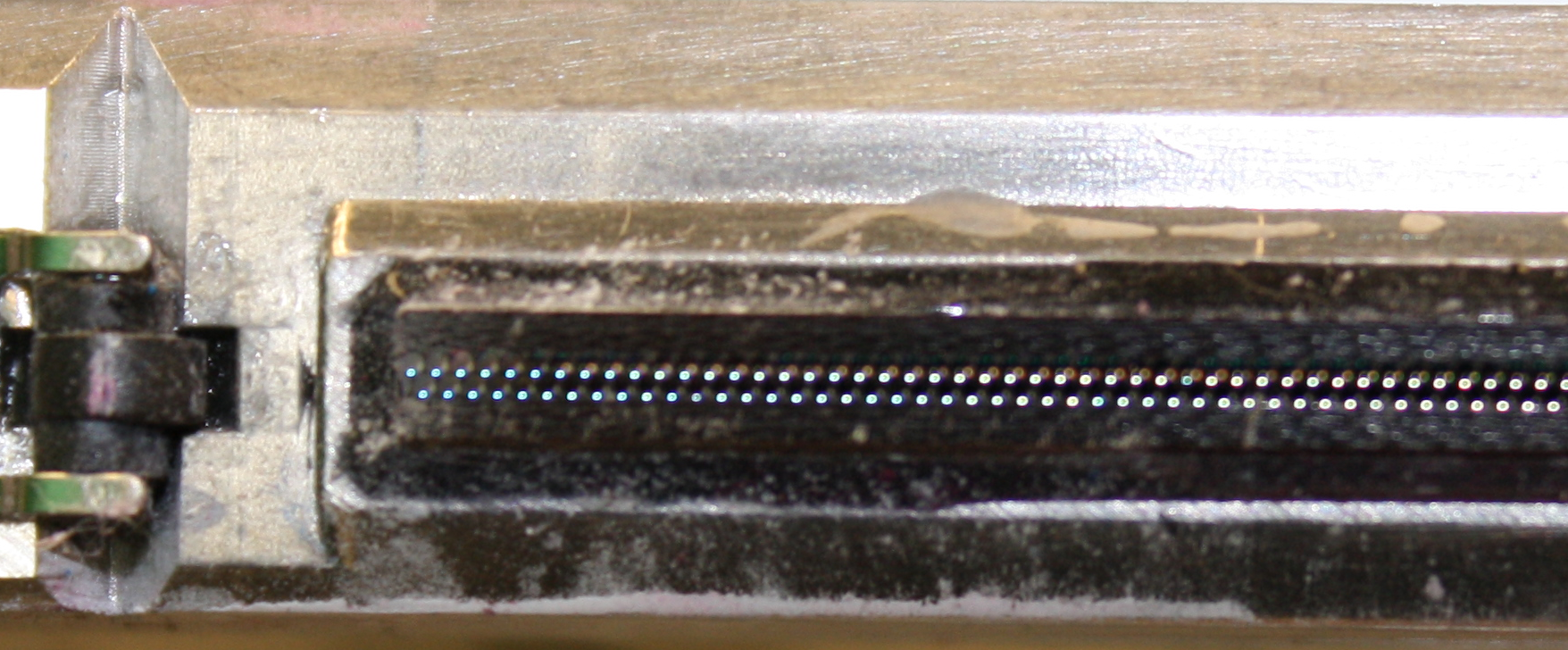

Laser printers are high-intensity LED imaging devices. A bar of LEDs with a density of at least 600 lights per inch is connected to the imaging computer and flash on and off at the intensity of 1200 flashes per linear inch of travel. That’s exceptionally high precision! These LEDs flash on to activate the conductivity of the photoconductive drum. This allows the charge applied by the corona wire to dissipate to the well-grounded steel bar underneath. If the printer does not have a substantial connection to the ground, this charge has no place to go.

A toner hopper agitates the toner powder, which is made of polystyrene, think Styrofoam, which sticks to any charge. After the drum is charged and erased, the parts that did not get erased will now pick up the toner as it rotates by the hopper gate.

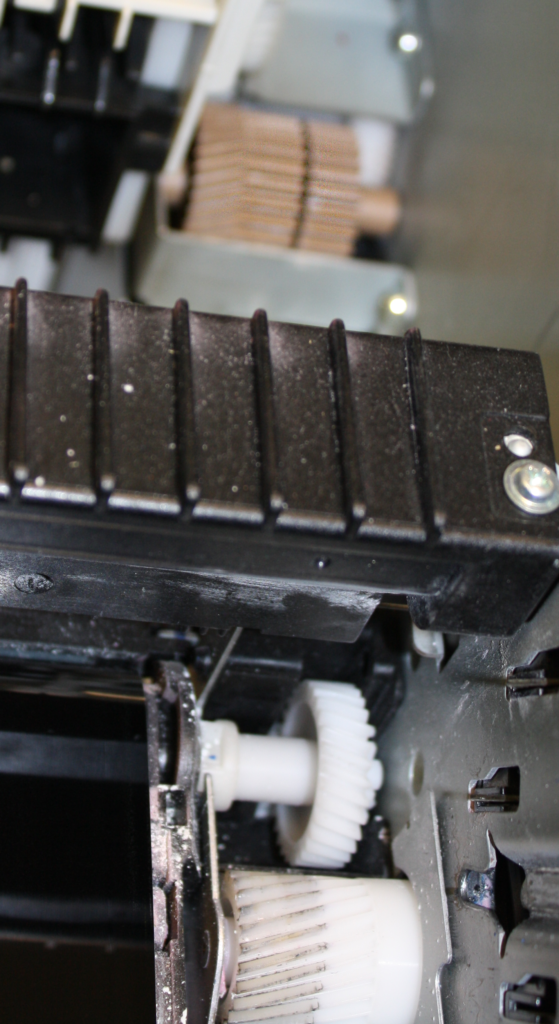

Laser printers are motor and gear-driven devices. Multiple stepper motors always have to be in perfect sync. Stepper motors run the rotation of the drums and the toner hoppers’ actions (1, 4, or 5, depending on the colors in the printer). Some motors run the media feed, the transfer belt, and the fuser rollers. Each of the motors has to run in sync by stepping tiny clicks of movement in match step with the flashing LEDs. This correct sync is dependent on smooth power frequency (hertz).

Laser printers are charge transfer devices. The transfer belt has an underlying corona charge wire that applies a high voltage charge. This charge is higher than the one applied to the toner drum, which means that the toner will jump from the drum toward the transfer belt, but lands on the media between them. This is incredibly precise. Too much or little charge, too fast or slow movement, too high or low gap, and this fails.

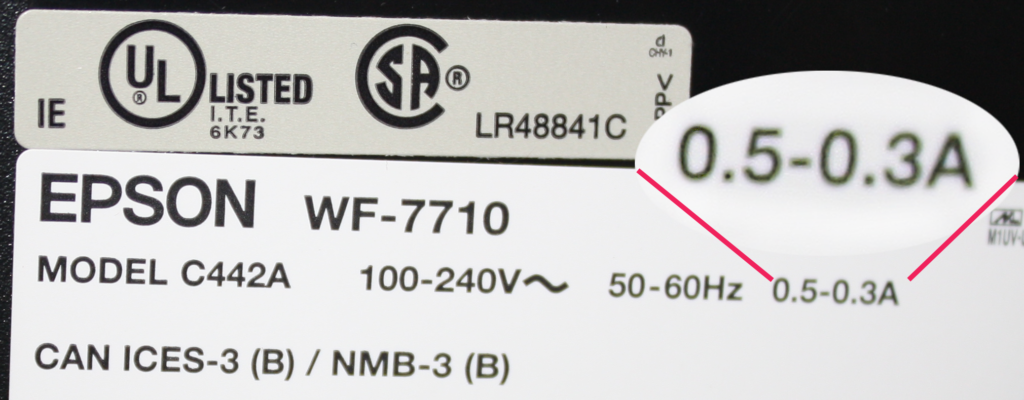

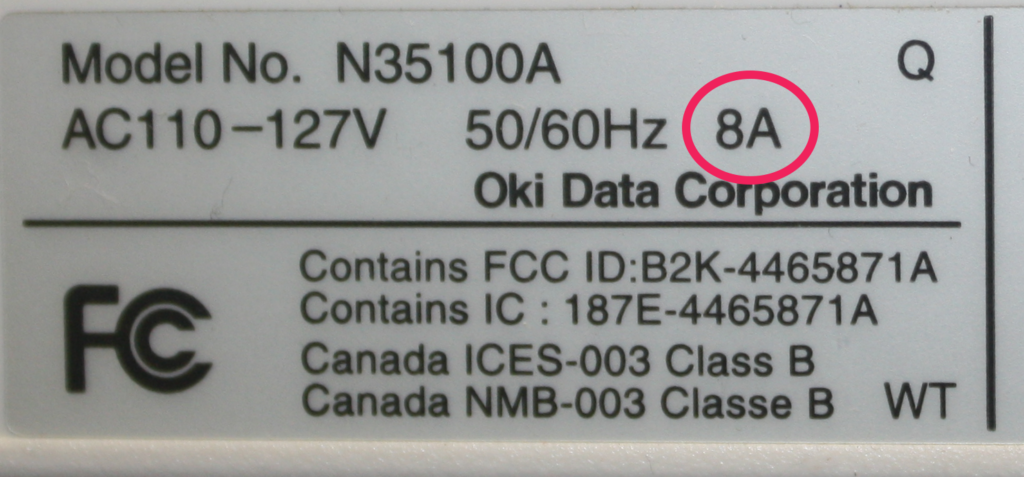

Lastly, laser printers are welding machines. The fuser is just as critical as everything else. The fuser rollers have an internal heating element that applies a precise even heat to the roller. On top, a thermistor reads the temp of the roller and adjusts the heating element every instant. These heating elements generate temps over 400 F and cover the area of the roller. The rollers also generate significant pressure using strong springs. The motor needed to turn these rollers, along with the heating, require considerable amperage. The required amps must be constant, and any fluctuation during printing and the job fails.

Power is critical to proper laser printer function. For example, turning on a blender or hair dryer while printing can cause interference. Other motors or appliances can cause a power drain.

When working with technical media like transfer media, this is even more critical. Problems on a few sheets of copy paper are not even noticed or even cared about.

Check out Part 2: Preparing Your Artwork