Conceived decades ago, 3D printing has emerged in recent years as a production tool for industrial designers, medical technicians, and hobbyists. Nowadays, 3D printers range from inexpensive desktop home printers to multimillion-dollar giant industrial robots (Fig. 1).

Additive process

Another term for 3D printing is additive manufacturing. It is a process of making three-dimensional, solid objects from a digital file. The creation of a 3D printed object is achieved by depositing successive layers of material until the entire object is realized. Each layer is a thinly sliced horizontal cross-section of the whole object. As it is deposited, each layer is fused to the previous layer to build a solid structure.

In this article, I’ll describe four of the most common 3D printing technologies in use today. Since 3D printing is a kinetic process and can be a bit challenging to understand, I’ve included a basic schematic illustration of each system and links to videos that show the processes in action.

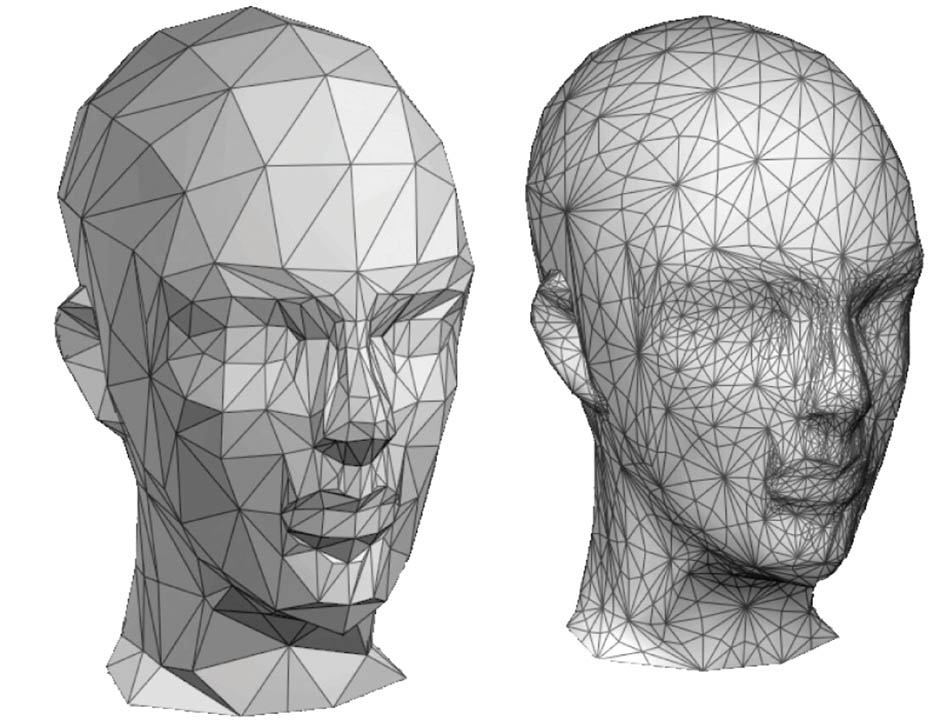

3D modeling

The basic principle of 3D modeling is structuring the surface of an object into polygons called vertices. Images of objects can be captured using a 3D scanner or generated in 3D software. The contour of the object, consisting of polygons is “mapped,” and a virtual model is generated that can be reshaped and surfaced. The more polygons a model has, the more detail can be created. (Fig. 2)

3D printing begins by creating a virtual design in a 3D modeling program and saved as in a 3D specific format. An existing object can be scanned with a 3D scanner.

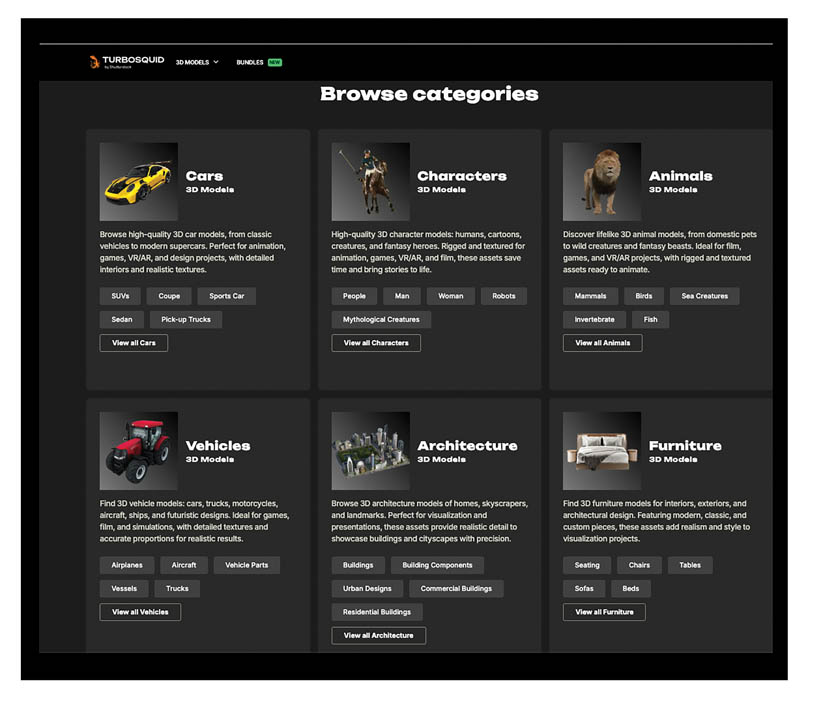

Modeling software includes tools that implement the design of three-dimensional models of objects or characters and often include supplemental features to flesh out models with realistic details. 3D modeling software and hardware can generate objects using tools and techniques that often include painting features to add textures and color.

Software that is used for 3D animation can also export to 3D printing compatible formats. Several companies offer premade 3D models such as cars, furniture, human figures, and animals that can be downloaded and manipulated in a modeling program. (Fig. 3)

3D printer formats

The data of the completed model is exported to a printer compatible format that is configured so that 3D printer software can interpret the model into consecutive layers. The two most common file formats for 3D printing are STL and VRML. STL, or stereolithography, formats 3D rendered objects containing a single color. STL is typically used with desktop 3D printers. VRML (pronounced vermal) with a file extension of WRL stands for virtual reality modeling language. This 3D format enables color printing on desktop 3D printers with more than one nozzle that emit different colors.

Additive manufacturing file format (AMF) is an XML-based open standard for 3D printing. AMF supports multiple colors. AMF files use a compression scheme that reduces the file size of the document. GCode format contains detailed instructions for a 3D printer to follow for each slice, like the starting point for each layer and the path that the nozzle or print head will follow in laying down the material. Some 3D printers have proprietary formats that contain instructions for a specific make and model of printer and the printer’s software. Fortunately, proprietary file formats are generated from STL or WRL files so that any software that can export to these common formats can be used to create the model.

Slicing

After the 3D model is rendered, and to prepare a file for printing, the 3D modeling software “slices” the model into hundreds or thousands of horizontal layers. When the sliced file is uploaded, the printer software uses the sliced data to print each layer. It reads each slice and its path along the cross section and gradually builds the object, fusing each layer to the previous one. These layers are deposited in a material such as plastic or metal, by the printer’s emitter heads and fused by a heating method or ultraviolet light.

Printing technologies

There are several 3D printing technologies, but they have one thing in common; they are all additive. That means that the material is built and not carved. They differ primarily in the way the material is deposited and how layers are fused together. What follows are descriptions of four of the most common 3D printing processes.

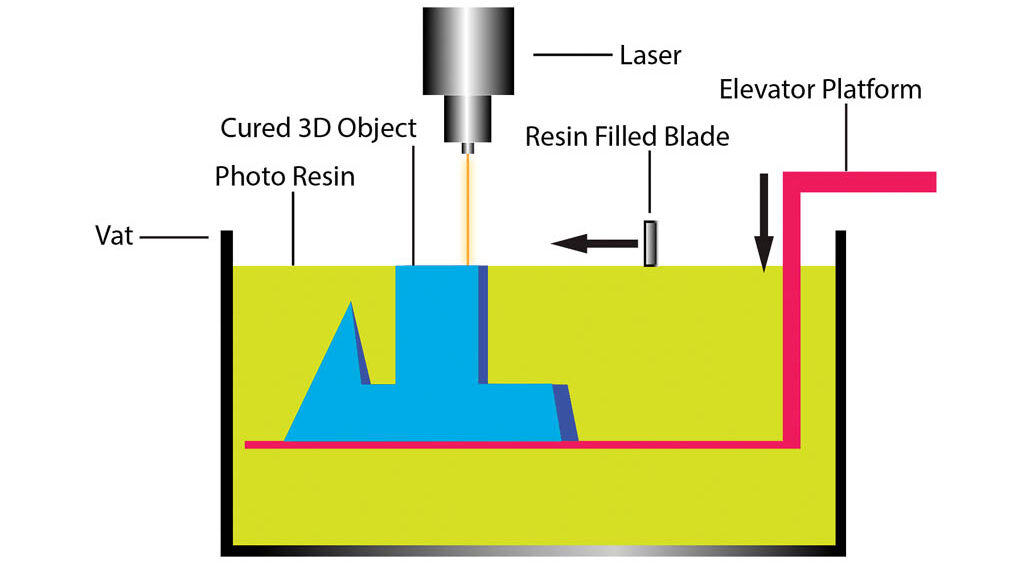

Vat photopolymerization stereolithography (SLA)

SLA uses a vat of liquid ultraviolet curable photopolymer resin to sequentially deposit material one layer at a time. (Fig. 4) It fuses the layers with an ultraviolet laser. The laser exposes a cross section of the object in the liquid resin to UV light, which cures and solidifies the pattern and fuses it to the layer below. After a layer has been traced by the laser, an elevator platform to which the object is attached, descends by the distance of the thickness of a single layer (0.05-mm to 0.15-mm).

A resin-filled blade sweeps across the top-most layer and re-coats it with fresh material. On this new liquid surface, the subsequent layer pattern is traced, joining it to the previous layer until the complete three-dimensional object is formed. The object is then cleaned, to remove uncured resin, and may undergo post-curing under UV light for full strength.

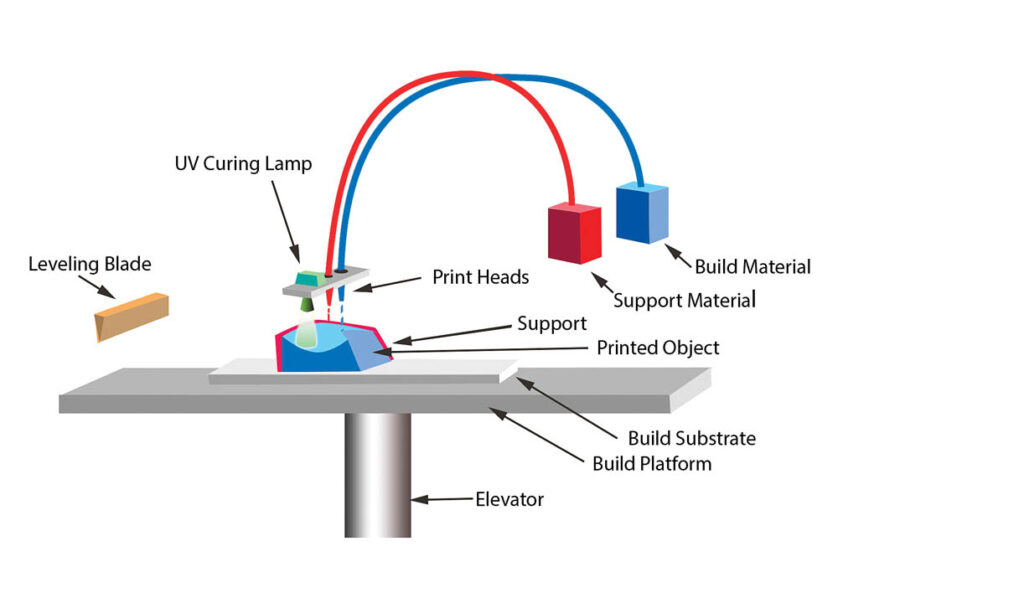

Material jetting

In this additive process, two nozzles supply the material in tiny droplets just like a desktop inkjet printer. (Fig. 5) One of the nozzles builds the 3D object and the other builds a support structure that stabilizes the object. The material is deposited layer-by-layer and leveled with a leveling blade. The material is hardened by an ultraviolet curing lamp that follows the print head. Poly-jet technology (multiple jets) is used to print objects with multiple parts and colors.

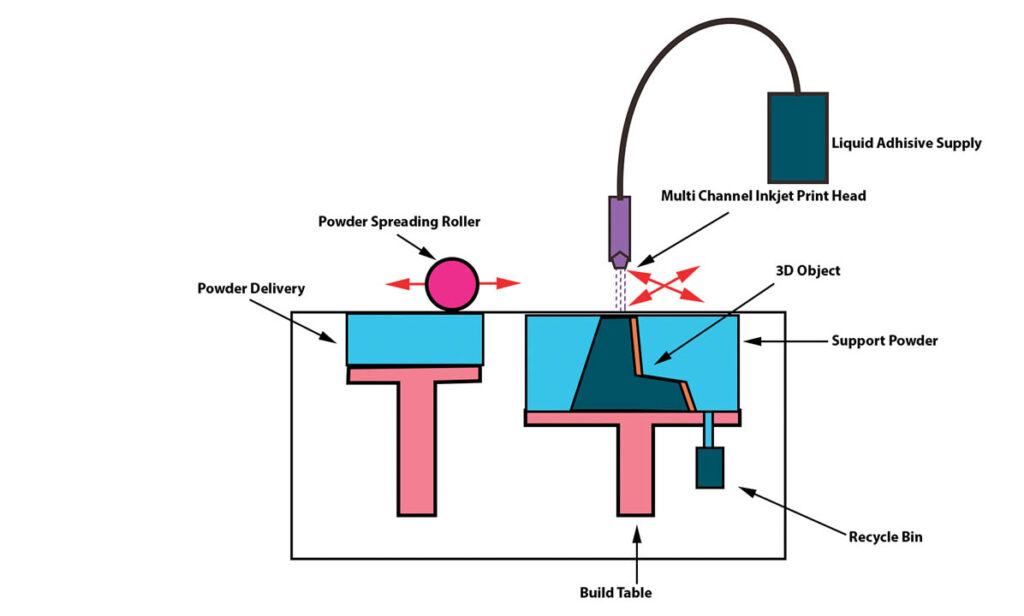

Binder jetting

This technology uses two components; a gypsum-based powder which is a form of plaster, and a superglue-like binder. (Fig. 6) In the build chamber, a roller spreads a layer of powder over the build platform. A nozzle jets binder into the powder in the shape of the cross section of the object. It uses inkjet printer heads that are similar to an inkjet paper printer to jet the binder into the powder. Once a layer is printed, the build platform descends the thickness of a single layer, and the roller distributes a new layer of powder. The process is repeated until the entire object is built.

When completed, the object is removed from the build chamber, and the excess powder is recycled. By coloring the binder, multiple colored 3D prints can be created. Binder jetting machines make good solid objects. Because they are essentially composed of plaster and glue, its use is limited to the creation of rigid parts.

Powder bed fusion selective laser sintering (SLS)

SLS uses a high-powered laser to fuse small particles of plastic, metal, ceramic, or glass powders into a 3D object. (Fig.7) The laser selectively fuses the powdered material by scanning the cross sections generated by the 3D modeling program on the surface of a powder bed, similar to binder jetting. After each pass, the powder bed is lowered by the thickness of one layer, then a new layer of powder is deposited on top with a blade. The process is repeated until the object is completed.

The surrounding untouched powder serves as a support structure for the object, eliminating the need for an auxiliary structure, which is an advantage over technologies like material jetting that build support structures as the object is being printed. Unused powder is recycled for the next print.

The 3D printing industry

3D printing technology is used across a wide range of industries because it allows for rapid prototyping, customization, and complex design fabrication that traditional methods cannot easily achieve. Here are a few examples of industries where additive manufacturing has become mainstream technology:

- Manufacturing and engineering for prototyping, to quickly produce and test design concepts prior to full production. Also, for tooling and jigs to create custom tools, molds, fixtures for assembly lines, and end-use parts for low-volume production of specialized components.

- Aerospace and defense to manufacture lightweight parts to reduce fuel costs and to easily produce objects with complex geometries such as turbine blades and ducts. It is also used for the rapid replacement of obsolete or mission-critical parts.

- Automotive for the rapid prototyping of design components, for custom tooling and fixtures, and for limited production runs

- Healthcare and medical to create custom prosthetics and implants specifically tailored to patients’ requirements. It is utilized for printing surgical guides and anatomical models for planning complex surgeries and for bioprinting tissues and organs.

- Architecture and construction to produce detailed scale models of buildings and landscapes, for building 3D-printed houses and construction components with concrete printing, and to manufacture decorative and functional elements like facades or fixtures.

- Consumer products for the rapid iteration of design ideas and for creating customized items such as eyewear, footwear, jewelry, personalized gadgets, and home decor.

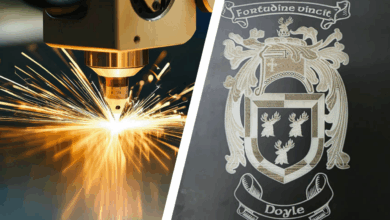

- Art, design, and fashion for sculptures, wearable art, stage props, complex geometric jewelry, and fashion accessories.

- Dental to precisely create crowns, bridges, dentures, and aligners.

- Food for culinary design of custom shapes, textures, and nutrition.

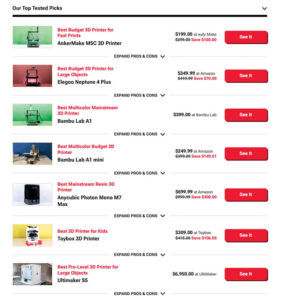

Personal printing

Domestic 3D printing for artists and hobbyists has seen a surge in growth over the past ten years. Because of the demand, the cost of a home-based 3D printer has dramatically decreased. Currently, prices range from $200 – $7,000. (Fig. 8) Printing 3D objects at home or in a studio on a small 3D printer that an artist scans with a hand-held scanner or designs in a 3D modeling program is very rewarding form of sculpture. Work of this kind can be seen in art galleries and museums.

3D printing technology has changed the nature of manufacturing, quite like 2D digital printing did in the 1990s. End users can manufacture parts for home repairs and the generate new objects at will. 3D printers are versatile with the ability to print objects with multiple colors, materials, and sizes. The effect of 3D printing on energy utilization, waste reduction, customization, product availability, medicine, art, industrial design, construction, and science is dramatic as this technology has been absorbed into the everyday workflow of industry.