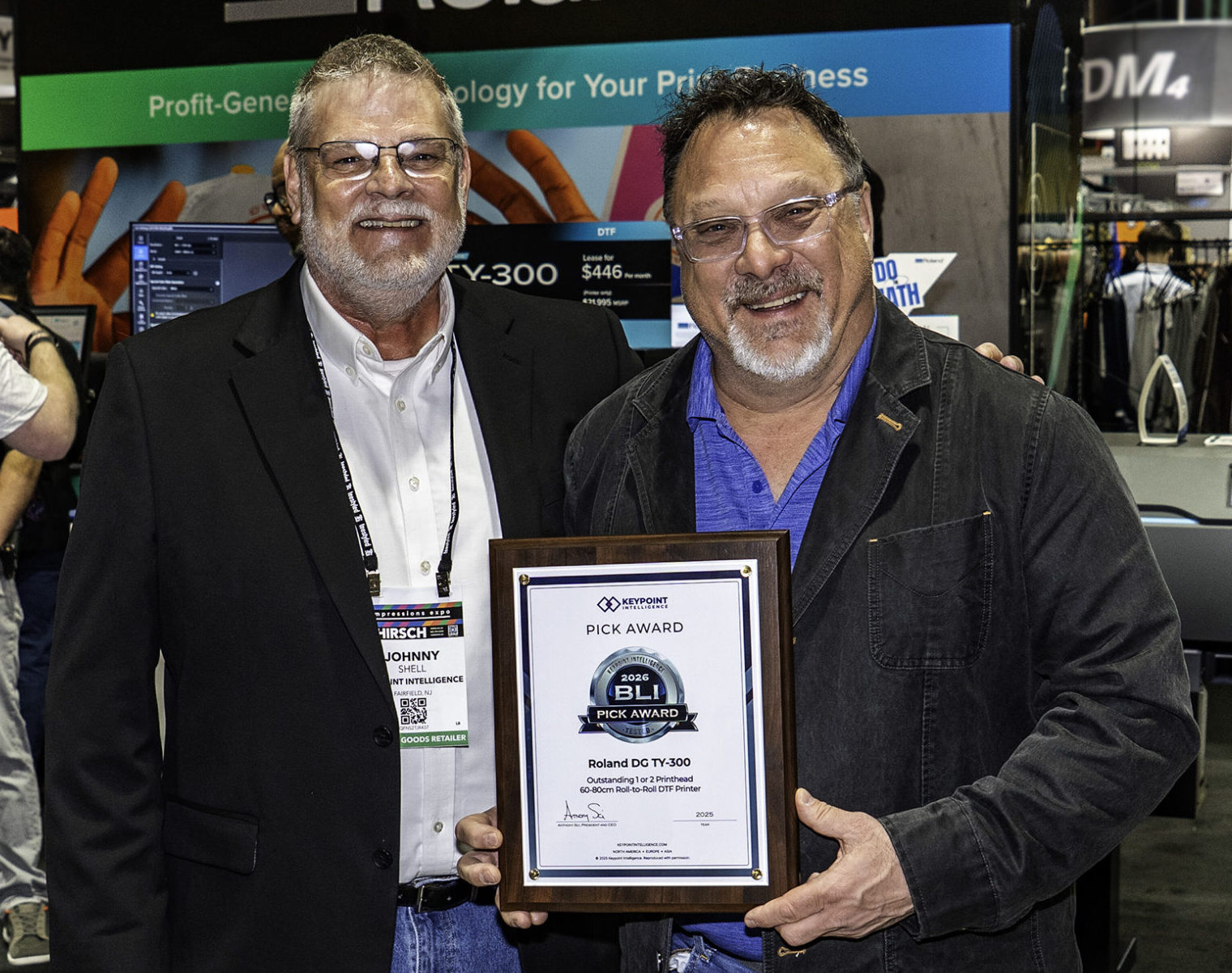

Roland DG wins Keypoint Intelligence BLI 2026 Pick Award

The TY-300 was recognized with the accolade of “Outstanding Direct-to-Film Printer.”

Roland DG, a provider of digital printing solutions, announced that the Roland DG TY-300 direct-to-film printer has earned a BLI 2026 Pick Award from Keypoint Intelligence, a global independent research organization that tests and evaluates print and imaging technology.

After undergoing comprehensive assessment across image quality, color performance, durability, productivity, and usability, the TY-300 was recognized with the accolade of “Outstanding Direct-to-Film Printer” in the one and two printhead (60-80 cm) category.

“The TY-300 delivered an exceptionally strong overall performance in our testing,” said David Sweetnam, director of EMEA/APAC Research & Lab Services at Keypoint Intelligence. “Its image quality was consistently impressive; with the largest color gamut we have recorded to date for a CMYK-only DTF device on white T-shirts and clear gains in vibrancy on dark garments in high-quality mode. These results position the TY-300 as a formidable competitor in the rapidly expanding direct-to-film market.”

Ryugo Nimura, president of Roland DG’s Global Sales and Marketing Division, said, “We are very honored to receive this Pick Award and proud that Keypoint Intelligence’s rigorous testing has confirmed the TY-300’s ability to deliver exceptional direct-to-film performance. This recognition underscores our commitment to supporting the evolution of the garment decoration industry and expanding the opportunities available to customers as they grow their creative and commercial capabilities.”

Analysis results

Keypoint Intelligence’s detailed analysis highlighted the TY-300’s superior color accuracy, noting that it achieved the lowest average DeltaE variance across its challenging suite of spot colors on white T-shirts, with only one color exceeding Delta E00 6.0. On black garments, the enhanced white ink laydown in high-quality mode delivered significant improvement in lighter tones, contributing to more accurate reproduction of difficult brand colors.

Washability was identified as another standout strength. Across 20 wash-and-tumble-dry cycles, the TY-300 exhibited no visible breakup of fine details or halftone fills, minimal color shift, and no reduction in stretch resistance, with both text and graphics retaining their clarity and appearance throughout testing. These results are said to demonstrate the TY-300’s reliability for garment decoration applications requiring long-lasting, high-quality output.

The printer also performed strongly in productivity tests, achieving 117.33 square feet per hour (46.93 linear feet per hour) in Roland DG’s recommended production mode, while a faster four-pass mode delivered output exceeding 188.11 square feet per hour (75.24 linear feet per hour) when speed is prioritized. Features such as white ink cartridge swapping during operation and nozzle-blockage compensation help ensure continuous operation, while the latest VersaWorks RIP provides streamlined spot-color optimization and advanced color management. Roland DG Connect further supports production visibility with cloud-based device monitoring, reporting, and business analytics capabilities.