Nazdar collaborates with Georgia Institute of Technology for 3D printing

This project seeks to revolutionize polymer powder bed fusion 3D printing.

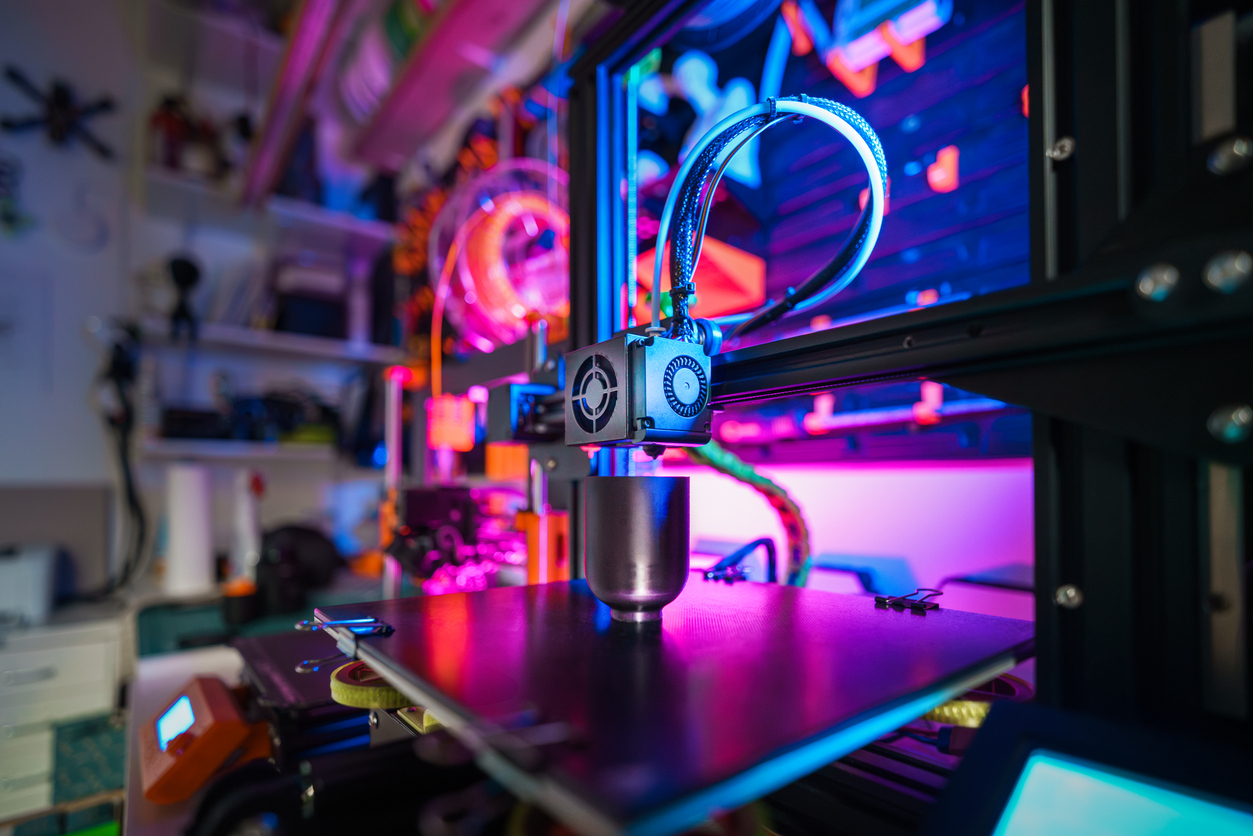

Nazdar Ink Technologies announced it has collaborated with the Georgia Institute of Technology’s Digital Design and Manufacturing Lab to explore advancements in 3D printing through a novel process known as Radio Frequency Additive Manufacturing (RFAM).

This project, led by Dr. Carolyn Seepersad and PhD student Matthew McCoy, seeks to revolutionize polymer powder bed fusion 3D printing by introducing a volumetric heating method, which promises to boost production rates, reduce waste, and improve energy efficiency.

Nazdar’s role in the partnership focuses on developing specialized fluids that optimize the RFAM process. Their expertise in inkjet formulation is key to tailoring materials that enhance the precision and efficiency of this promising 3D printing technique. If successful, the collaboration could impact industries such as aerospace, automotive, and medical devices, where faster and greener production methods are increasingly crucial.

While results are still pending, the potential for RFAM’s broad application is significant. This project also draws on the innovation of Neil Hopkinson, inventor of the High-Speed Sintering process, whose work forms a foundation for this new approach.

According to Nazdar, this project is a further demonstration of its commitment to pushing boundaries and innovation with inkjet.