A lot of time is spent working with wood in the awards industry. From the traditional plaque to ornaments, to trophy bases and more, wood substrates continue to rise to the top of customer requests. Over the years, awards retailers have worked with many different wood species and substrates: anything from natural wood like walnut and cherry, to substitutes like veneer and thinner boards are all familiar faces.

If shops spend so much time working with wood, it goes without saying that there should be equal emphasis on the methods used to decorate it. Many retailers are probably familiar with lasering wood, but with the advent of sublimation, and now UV-LED printing, the methods to decorate this popular item have expanded quite a bit in the past few years. Because of this, it’s a good idea to revisit the many ways currently available to decorate wood.

BEST METHODS

Let’s start with the basics. You might be asking yourself, what is the most popular or best way to embellish wood? With all the options out there, it’s a fair question. But the answer isn’t black and white.

When it comes to the most popular, the answer is: it depends. “Wood can be decorated in countless ways and the market seems to be rapidly evolving with the arrival of new technologies and exciting trends,” states Josh Stephens, Trotec. “The processing capabilities available today make it an exciting time to create unique and customizable products.”

If you’re wondering which technology is best to use with wood, again the answer is it depends. Rachel Tindal, LogoJET, points out that the effect you want to achieve and the end application factor in to this determination; each technology has its own benefits. “Laser engraving creates a permanent imprint and depth, while other techniques like sublimation embed color into the wood surface, allowing the natural grain to show through,” she elaborates. She adds that UV printing offers raised textures as well as color options.

The technology you choose also depends on your available equipment, skill set, and even customer base. Brad Madison of Center Trophy Co. in Omaha, Nebraska, states that laser engraving is by far the most popular in his shop. Aside from being one of the original ways to decorate wood, it’s also one of the most permanent. Also keep in mind the substrate you’re working with. “You’re at the mercy of the wood – the substrate does affect your end result,” he adds.

Since there are so many methods to choose from, and narrowing it down to the most popular or best is tough to do, it’s helpful to be aware of all of the options available. Stephens adds CNC technology to the list in addition to sublimation, UV printing, and laser engraving. “CNC machines are popular because they can cut and shape wood into most sizes including large-scale products,” he points out. “This type of system can transform wood into just about any shape including plaques, boxes, full-sized furniture, and much more.”

Sandcarving also makes the cut. “Sandcarving wood is generally a quick option and allows for paint-fill or a clear coat to reveal the natural wood grain,” states Liz Haas, Rayzist. She adds that this option is unique because you can be creative with either revealing the natural grain, adding various colors, or combining the two.

WORK IT

Breaking it down by technology, chances are most awards retailers will at some point use a laser to embellish a wood product. Whether it’s a plaque or keepsake box, engraving offers great end results when executed correctly.

If you’re unsure of how to approach laser engraving wood, Stephens has a few pointers. “Wood type is an important factor when it comes to how intricate the material can be decorated,” he emphasizes. “Denser wood is typically harder to cut or engrave, and darker wood limits the level of contrast that can be produced.” He adds that wood with higher grain content can cause problems with the visibility of the image.

Madison adds to that point, stating that some wood pieces even have different stains on them that can affect the end result. He cautions to do your research before purchasing because not all wood products are equal in terms of quality.

Perhaps you’re interested in taking the sandcarving route, in which case, Haas has a few recommendations. “Softer wood materials etch quicker than hard wood materials,” she points out. “In cases of softer wood materials, the artwork may have to be modified to reflect the wood grain appearance.” She adds that some surfaces need to be treated with a light coat of lacquer to act as a sealer, which assists in bonding the photoresist stencil to the surface.

If sandcarving or laser engraving aren’t what your customer is looking for, sublimation or UV printing might be the ticket. “UV printing can be applied to any species of wood,” Tindal points out. Even more appealing is the ease in which it’s done. “The wood substrate can be loaded directly onto the flatbed of a UV printer and the bed automatically adjusts to position the print head at the proper distance for printing,” she notes of the process. “Artwork is opened into the RIP software, and settings are selected to determine how many layers of ink to apply to achieve the desired finish.” From there, just send the job to print, and since the ink is cured while printing, the product is immediately ready for use.

SHAPE UP

Now that we’ve discussed the available decorating technologies and some considerations to keep in mind when applying them to wood products, let’s take a look at the substrate side of things. Sources agree that the grain and general makeup of the wood itself factors in to working with it, but so does the shape of the product itself.

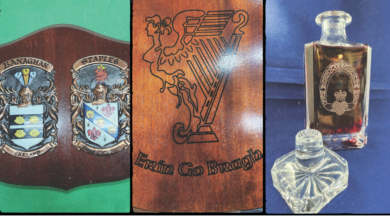

Starting simple, plaques are one of the most well-known and worked-with wood products. According to Madison, these have been around for a long time, and in the beginning, laser engraving was pretty much the only option to decorate them. And of course, lasering wood plaques almost always yields predictable results.

But when moving on to something a little more complex, say a round ornament, things can get trickier. When it comes to odd-shaped items, a little experience goes a long way regardless of the technology you’re using to decorate them. “Decoration of odd shapes requires skill and experience that is obtained over time,” Stephens believes. But that doesn’t mean all hope is lost. “There are a lot of online resources available to assist with mastering this … (and) there are a lot of things that can be done to assist with processing the material.” For example, jigs are one tool that can be used when lasering items like a round wood ornament.

Jigs aren’t just for the engraving process, either. “Custom printing jigs for UV printers can be manufactured to hold odd-shaped items in place on the flatbed,” Tindal points out. “There are also rotary printing attachments that allow for full 360-degree UV customization on cylindrical or tapered objects.”

If sandcarving an odd shape, there are just a few pointers to keep in mind. “A photoresist stencil makes the project easy to etch, as it is flexible and conforms to curves or odd shapes,” Haas says. When working with a curve, be sure to create your artwork on a curve to help lay the image out correctly. “It is important to blast at a 90-degree angle especially over curved areas,” she finishes.

No matter which technique you choose, it’s a safe bet that your customer’s wood item will be a natural hit. “(Retailers) that are skilled and experienced with wood processing that also own the proper equipment can offer highly profitable services and operate an extremely rewarding and lucrative business,” Stephens finishes.