Wood products are a highly popular medium in the awards, recognition, and gifting industries. Wood is recognized as a high quality, stand-alone product and an enhancement for other mediums, such as glass and acrylic. Wood is easy to personalize with many different techniques. Laser engraving, routing, direct-color printing, sublimation, and metal plates are all possibilities for decorating or personalizing wood products. Understanding the desires of your customers will help you choose the best wood medium to achieve the best results.

Uniqueness

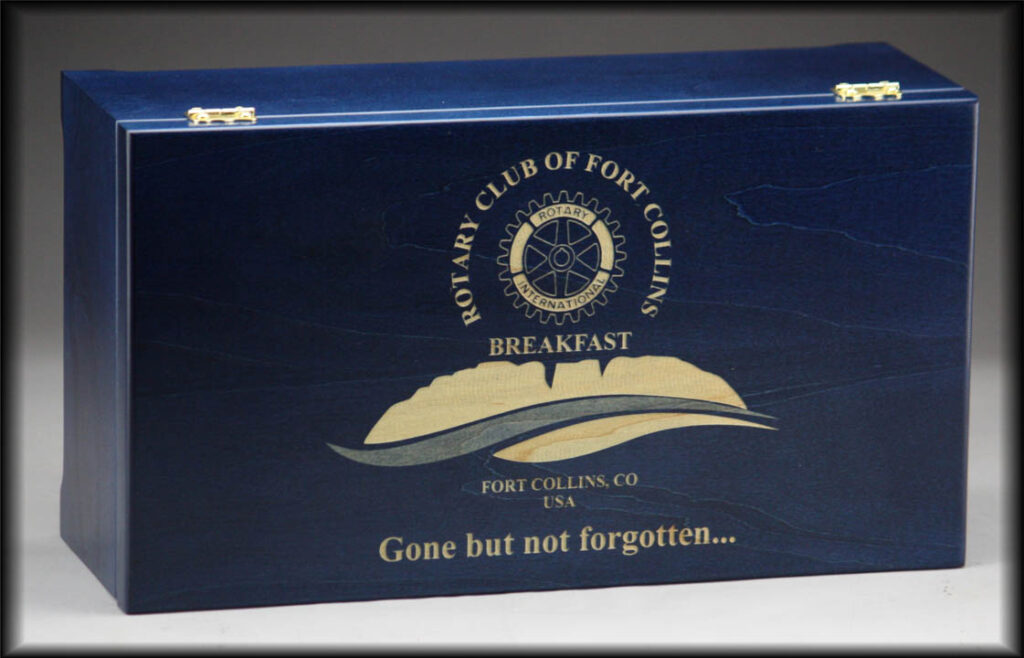

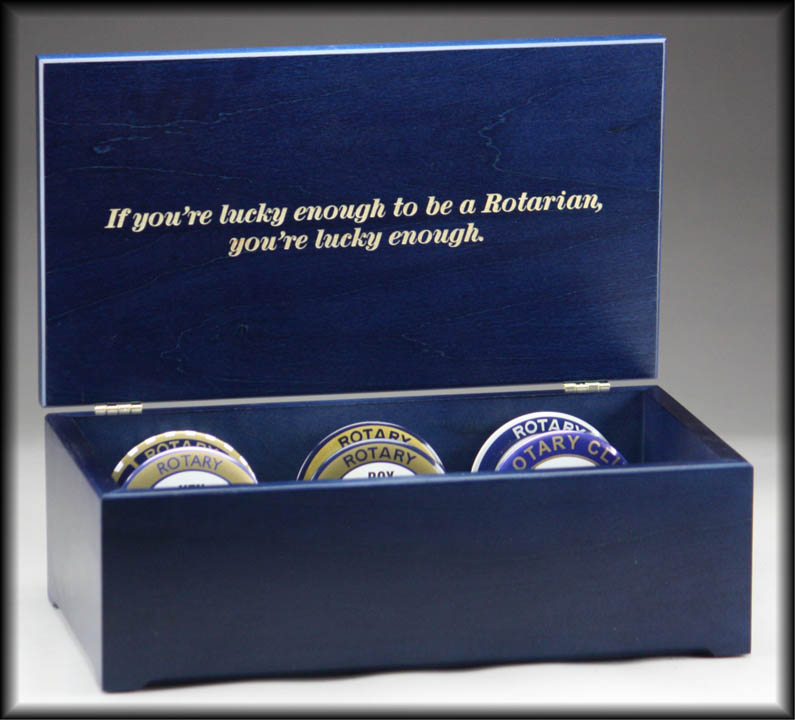

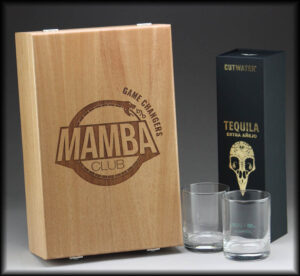

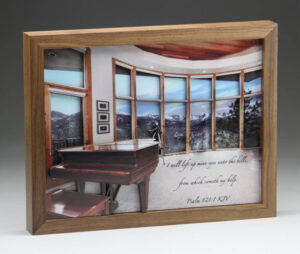

The graining in most of the woods is what makes each piece unique. Due to the uniqueness and natural beauty of wood, it carries a higher perceived value. Wood is associated with high-end products that are used for heirloom-type gifts and awards. Many corporate gifts, achievement awards, educational awards, personal gifts, and memorial products are made from wood due to their monetary and perceived value. Even smaller products such as nametags, bag tags, Christmas ornaments, and coasters are great products that can be produced from wood that carry higher perceived value. Wood boxes, urns (human or pet), picture frames, achievement plaques, etc. are all products that can be customized and personalized to become family keepsakes and heirlooms.

The graining in most of the woods is what makes each piece unique. Due to the uniqueness and natural beauty of wood, it carries a higher perceived value. Wood is associated with high-end products that are used for heirloom-type gifts and awards. Many corporate gifts, achievement awards, educational awards, personal gifts, and memorial products are made from wood due to their monetary and perceived value. Even smaller products such as nametags, bag tags, Christmas ornaments, and coasters are great products that can be produced from wood that carry higher perceived value. Wood boxes, urns (human or pet), picture frames, achievement plaques, etc. are all products that can be customized and personalized to become family keepsakes and heirlooms.

Sustainability

Sustainable wood is a very good ecological selection when thinking about the environment. When wood is selected from a sustainable forest, it is one of the most environmentally friendly mediums used in the industry. The sustainable certification assures that the forest has proper management and logging techniques. Strip harvesting is not allowed. That ensures erosion does not occur and nature (wildlife) is not thrown out of balance. Forest management includes planting five trees for every tree harvested and the dead trees and undergrowth that feed large uncontrolled fires are removed. Uncontrolled fires normally occur in forests that forest management is not allowed in. It is critical for the environment to use good forest management techniques and to keep using and harvesting lumber. In a climate-conscious world, educated buyers realize the benefits of using wood rather than metal, glass, or plastic. It can be a win for all.

Sustainable wood is a very good ecological selection when thinking about the environment. When wood is selected from a sustainable forest, it is one of the most environmentally friendly mediums used in the industry. The sustainable certification assures that the forest has proper management and logging techniques. Strip harvesting is not allowed. That ensures erosion does not occur and nature (wildlife) is not thrown out of balance. Forest management includes planting five trees for every tree harvested and the dead trees and undergrowth that feed large uncontrolled fires are removed. Uncontrolled fires normally occur in forests that forest management is not allowed in. It is critical for the environment to use good forest management techniques and to keep using and harvesting lumber. In a climate-conscious world, educated buyers realize the benefits of using wood rather than metal, glass, or plastic. It can be a win for all.

Wood byproducts are also a good material source for less expensive products. These products are plywood and MDF. Care needs to be taken when choosing these woods, as when buying solid woods, that they follow certain environmental guidelines. Care should be taken that the material is labeled to be formaldehyde-free. Also, laser engravers need to make sure glitter is not used in the manufacturing of the plywood and MDF boards. The glitter is metal and will affect the cutting of the plywood and MDF.

Most domestically manufactured nonstructural plywood and MDF boards are glitter-free and all are made with formaldehyde-free glues and binders.

Decorating

Many times, more than one technique of decorating and personalizing is used on the same piece. Solid woods are the nicest for laser engraving to get the most consistent natural results without the use of color fills. To get the best contrast when laser engraving without the use of added color fill, it is important to choose the best wood species. Alder, cherry, and maple are all high-quality wood species that work very well with lasers. For best results using direct-color print or laser engraving, it is important to have a good finish on the woods.

A durable lacquer finish is a good choice. Having a good finish on the surface of the wood ensures that the laser residue can be cleaned easily after the piece is lasered. For direct-color printing, using UV-cured inks, having a good finish that pairs well with the inks is important. Printing with unfinished wood can tend to allow the ink to bleed or soak into the grain of the wood. This can still be a desirable look — more rustic if you will. It is important to know how your personalization techniques behave and act with various wood species and grains as well as using a finish or leaving unfinished.

Staining

A newer trend is going toward colored woods. There are a few ways to achieve a colored wood piece. Transparent stains and opaque stains, colored lacquers, or paint work the best to bring out the richness and uniqueness of the graining. Each stain looks unique on different species of wood. For example, a transparent blue stain looks totally different on maple (the blue stain stays truest to its color because of the light color of maple) versus alder (the blue stain will be slightly darker on the medium tone of alder) versus walnut (the blue stain will appear closer to a navy-blue color as walnut is already naturally dark in color). This coloring gives products a very new look without losing the beauty and uniqueness of wood.

A newer trend is going toward colored woods. There are a few ways to achieve a colored wood piece. Transparent stains and opaque stains, colored lacquers, or paint work the best to bring out the richness and uniqueness of the graining. Each stain looks unique on different species of wood. For example, a transparent blue stain looks totally different on maple (the blue stain stays truest to its color because of the light color of maple) versus alder (the blue stain will be slightly darker on the medium tone of alder) versus walnut (the blue stain will appear closer to a navy-blue color as walnut is already naturally dark in color). This coloring gives products a very new look without losing the beauty and uniqueness of wood.

This technique can be used on solid wood or on plywood, MDF, and veneers. Whether your customer needs high-end boxes or nametags, the color can give each product a unique look. Many times, the color can be incorporated into company logos or school mascots/logos and colors. When using stains, it can also be important to adjust the speeds and powers of the lasers. When laser engraving on a light wood with a darker stain, a very nice contrast can be attained with a light engraving (less power) just to remove the stain. Conversely, with a light stain on a darker wood, a higher power will give great contrast and results. Direct-color printing is also a very viable decorating option for stained woods and works exactly as it does on any lacquered surface. Sometimes, for direct-color printing opaque colors, choosing a white finish (stain or lacquer) is the way to go so that when vibrant color is applied, the white base ink is not needed. This technique is normally used on MDF material when grain is not important.