Why is Sign Design So Seemingly Difficult?

Learn how to overcome the sign design conundrum

When I was hired by a sign company as a graphic designer to design signs, I quickly discovered I would have to create designs that would need to be built into a dimensional product. See, I come from the print world. I assumed my designs would just work. My design skills have immediately expanded into graphic designer/sign designer. Before this said job, I had no idea what a sign designer was. I had to quickly learn to create drawings that amount to a plan to build, among many other things. I had no idea where to start.

During my first day at work, I immediately realized that sign design is much more than design. Sign design (as it is mistakenly named) requires a graphic designer to know how to create a technical drawing called a mounting detail and even a ground sign installation page.

Even more, a design I create would be more than just a fanciful graphic design; it would have to accomplish two, possibly three, things:

- Provide instruction to a viewer

- Properly convey an identity (such as a brand) for a company or organization

- My design may also have to include wayfinding to guide a pedestrian or driver to a destination

This was all new to me! Where do I start? And how long will it take to learn this so-called sign design?

A question about learning: how long does it take someone to learn graphic design? One year, two years, three years? It varies on the person. When you find an answer to this conundrum, you may come closer to an approximate time it will take to learn professional sign design. In some cases, it may be safe to add a couple of years to the answer.

At work, my first question to the boss was, “Why is a specification page and site plan a part of outdoor sign design? I am a designer, not a technical drawing expert. Are there any example drawings laying around for me to look at?”

My boss’s answer was not helpful, “We are going to waste a lot of time going back-and-forth with revision after revision until I like what I see.”

My naive response was, “and how do I learn anything from that process?”

He replied, “You learn only if you ask enough questions, and in time, we will see if you can figure this out or not.”

Wow! I was floored.

Fifteen years later, I walked into a local sign company to pick up a check. Today, I subcontract sign design and technical drawing work for many companies, this one included. While I was there, I met their new graphic designer. She was smiling. She had just finished the company Christmas card. I heard someone say, “Send it to get printed right away.”

The protocol for the print industry is mostly: design it, approve it, send it, print it, send it out, cover it, display it, hang it or stick it as a label on a product. Basically, a great number of graphic designs become a print, a two-dimensional graphic.

With the approval of an outdoor sign design (and most other sign designs), a design file is converted into a production file for sign manufacturing. With sign making, there is measuring, cutting, sanding, bonding, welding, riveting, drilling, peeling, reverse peeling, mask-ing, laminating, and many other processes. Simply put, there are a lot of labor and fabrication techniques employed to make a sign.

Sign manufacturing is such an unknown concept to the public that if you try to explain it to someone, most people look at you with a blank stare. To them, outdoor retail signage is just part of the landscape, a given. Who cares? I need a coffee, where is Starbucks?

A great deal of outdoor signage represents identity and branding, two things that elude the general public. It is such a foreign concept for anyone on the street to know anything about a business’ identity or branding signage.

On the other hand, people understand product brands with no problem. Mention hamburgers or chicken wings. People know exactly where the closest In-N-Out Burger or Buffalo Wild Wings is located. Products have value. Signs have temporary value and are used as a momentary visual tool to achieve a means to an end. After that, signs are taken for granted. Remember, the public pays nothing to interact with signs, and signs have no taste at all.

Within a sign business, once a design is complete and a customer approves a design, it must go directly to a sign estimator for pricing. This process is usually done without the knowledge of a designer, outside of the design department. The sign business is a business. Once a customer approves a sign, a design file must become a production file and be sent to a sign fabricator. More often than not, a completed sign design is manufactured, not printed.

A designer, any designer, working for a sign company will struggle with learning their graphic design/sign design position until they accept and absorb the following three rules.

Sign Design Rule 1: You have to want to learn. This attitude is a pre-qualification to learn anything. There are many books and schools on the subject of graphic design. But there are no how-to books or formal schooling for sign design. This is a fact. Although this fact is slowly changing. The negative to this conundrum is, you have to learn it. The positive side is, you increase your skillset portfolio.

Sign Design Rule 2: As a designer, you must look beyond the print world. Immediately, you must begin to look at design from a point of view based on a physical environment. That means you have to visually see where a sign will be installed and how people interact with it. Why? Because you will need to assess the value of its design. Sign design must consider angles, heights, and distances, as well vehicle and people movement. It must also consider letter heights, letter stroke, logo recognition, user readability, and usability, as well as aesthetics. People will use your design, emotionally, to make decisions. If you design well, you might get an “oooh” or “aaah”.

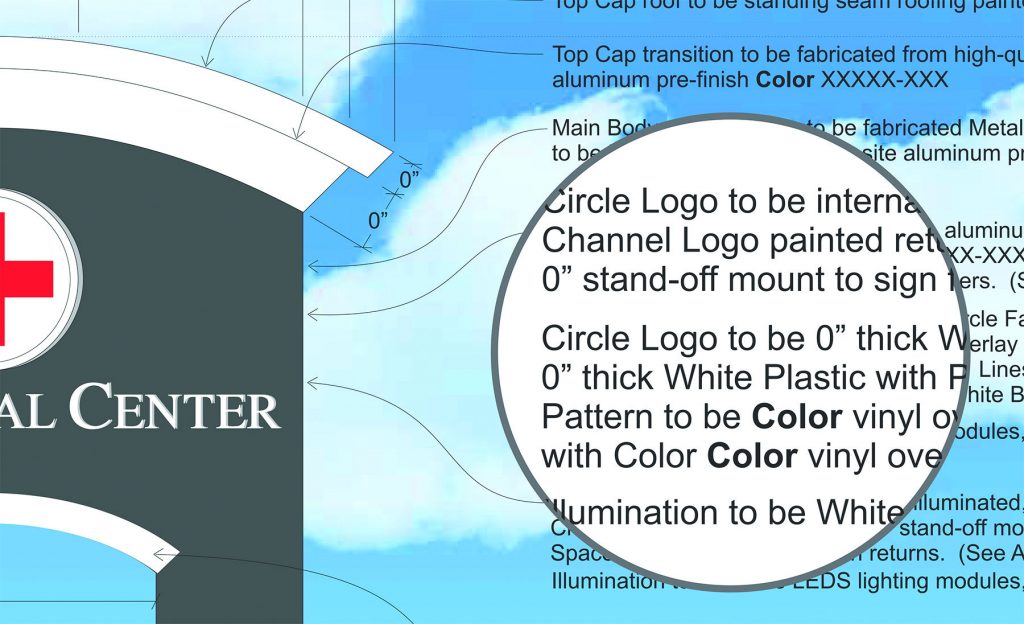

Sign Design Rule 3: An acquired sign design skill is more than just design. You will be required to know how to write a basic specification for a sign, assign Pantone Matching System (PMS) colors for paint, select vinyl from a swatch book, understand the basic tenets of drafting, such as scale and dimensioning, among a host of other things. But don’t fret, it can be learned.

Look at it like this, if you ever design a logo for a company, immediately the design will be sent to a sign company to be qualified. Every design created outside of the sign industry must be submitted to a sign company in order to be built. If a graphic design does not meet a minimum standard for manufacturing, it is rejected as “we can’t build this.” The design is then sent back to the original designer to be changed, to be modified. If a graphic designer is at a loss for what to do in order for a graphic design to be made into a sign, this is the main reason to learn professional sign design. Ask a professional sign designer what this means.