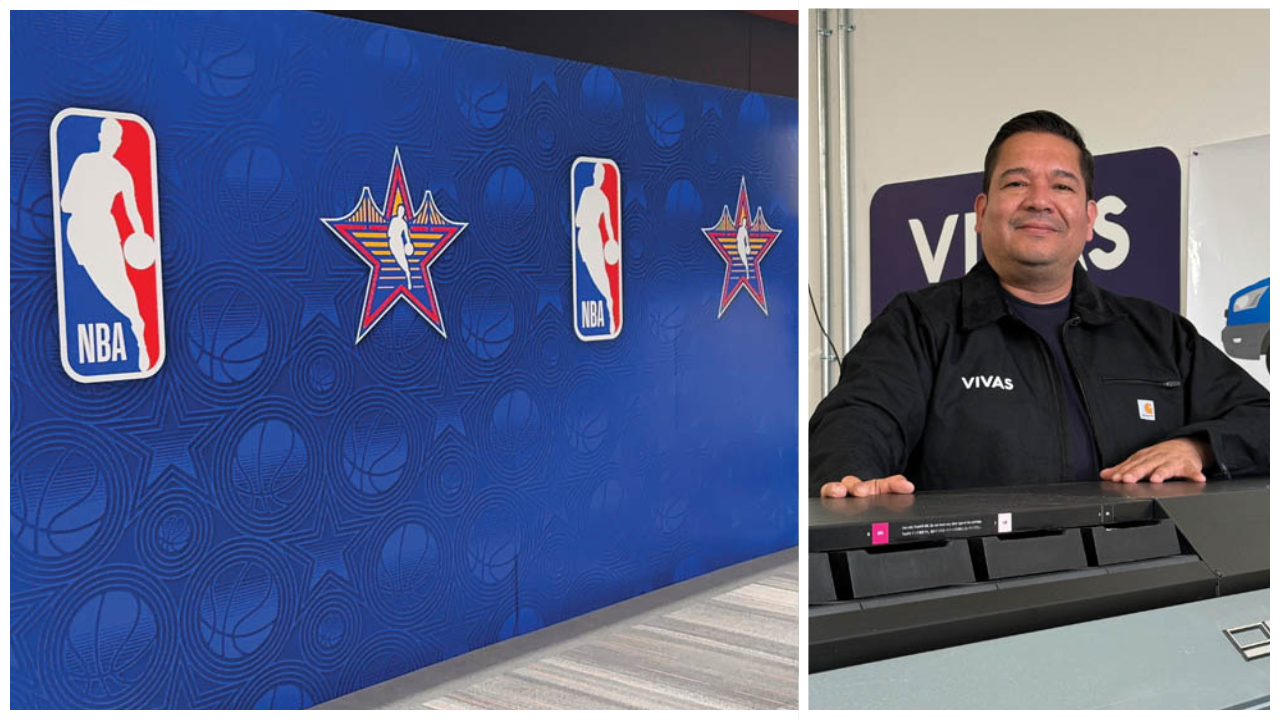

No stranger to big projects, Luis Vivas, founder and CEO of VIVAS Inc. in San Francisco, recently completed a high-profile set of graphics on a very tight deadline for the 2025 NBA All-Star Game.

We talked with Vivas about how they landed the project, what elements were required, and how they managed to produce and install approximately 8,000 square feet of graphics in two short weeks.

Q: How did you win this exciting project?

A: This opportunity came to us as a result of the printing and branding work we completed for the 2024 NBA events. Additionally, over the past year, we’ve made significant improvements to our website, optimized our keywords, and enhanced our digital marketing efforts. These changes have helped increase our visibility and offer additional proof to new and existing clients of our ability to execute exciting projects like this one.

Q: What was the timeline you were working with?

Q: What was the timeline you were working with?

A: It was an intense project that lasted two weeks, running right up until the day before the event. Given the scale of the project and the many last-minute additions, we had to work efficiently to meet deadlines.

At 7 a.m. on a Friday, two weeks out, our clients ordered six double-sided pole banners measuring 5′ X 14′, and 12 5′ X 5′ decals of the NBA All-Star Game logo — all needed that day by 6 p.m.

For this portion of the project, we used our Roland DG TrueVIS AP-640 latex printer to produce the pole banners and ran the logo decals on our TrueVIS VG3-640 eco-solvent printer/cutter. These graphics were completed at 4 p.m. and delivered at 5 p.m. Without our Roland DG printers, we could not have made it happen.

Q: How did you break down the project in terms of production and installation?

A: With two project managers, myself and Jefferson Vertiz, we were able to divide responsibilities effectively. We formed dedicated production and installation teams, allowing us to manage multiple simultaneous rush projects without compromising quality or missing any deadlines.

Q: Did the scope of the project expand as you worked on it, or was it pretty much as initially planned?

A: The project kept expanding as we went. Our NBA clients kept adding elements, and new clients, such as event sponsors, came in through recommendations from those we were already working with. This made the project even more dynamic and exciting.

Q: What were the graphic elements you produced?

A: We worked on a wide range of elements, including wall graphics, window graphics, and banners, as well as signs on foamcore, acrylic, and PVC, decals, and more. Each piece contributed to creating a cohesive and impactful visual identity for the event.

Q: Given the wide scope of this project, which printers did you use to complete the various elements?

A: We used our Roland DG TrueVIS VG3-640 and VG2-640 eco-solvent printer/cutters, as well as our TrueVIS AP-640 latex printer. Having both ink technologies operating with VersaWorks RIP software and True Rich Color presets made it easy to hit brand colors across a variety of media and allowed us to choose the best device for each element of the project. We were able to provide excellent and consistent quality, along with precision and efficiency, which were essential for a project of this scale.

Q: What media did you use?

A: We worked with a variety of high-quality materials, including 3M vinyl 40C and matte lamination 8510, General Formulations optically clear media, and HEXIS decals, along with foamcore, acrylic, and vinyl banner media. Each of these materials was selected to ensure a premium look and durability throughout the event.

Q: How did you choose the output devices for each part of the project?

A: With such a large volume of graphics required and the short turnaround, there was no time for color proofs — the NBA clients had to trust us — and by having three printers in-house, each with True Rich Color presets, we got the colors we needed. Having a range of devices also contributed to our efficiency and enabled us to deliver various elements on time, often the same day.

We chose to use our Roland DG TrueVIS VG2 and VG3 eco-solvent printers to produce most of the graphics because of their color vibrancy, durability, and fast production capabilities. Eco-solvent inks provided the best balance of quality and efficiency for many elements of this project.

We also used our TrueVIS AP-640 latex printer, which also provided outstanding speed and quality, to deliver graphics that were dry and ready to go within the tight deadlines set.

Q: How important was color matching?

A: Color accuracy was crucial for maintaining NBA brand consistency. We used Roland DG’s color management system to ensure perfect color matching across all materials.

The Roland DG printers enabled us to achieve exceptional graphic results. The precision, color range, and consistency of these machines, as well as their ability to handle large print volumes under tight deadlines, allowed us to execute this demanding project successfully.

Q: Do you have an estimate of the total square footage printed for this project?

A: The total square footage was approximately 8,000 square feet, but it felt like we wrapped all of San Francisco in vinyl!

Q: How often do you get rush jobs for events, both large and small, and how often are you able to take them on?

A: We handle rush projects frequently, and this experience has reinforced that we are fully prepared for these types of high-pressure events with tight deadlines. Our talented team, the advanced devices we use, and our efficient workflow allow us to take on these types of jobs without hesitation and exceed the expectations of our clients.

Our team was dedicated to producing excellent graphics for this important event, and having the right equipment makes all the difference. The NBA coordinator and client told us that they had never seen a printing company stay open 24 hours to accomplish production for the NBA All-Star Game weekend.

Q: How were the graphics received?

Q: How were the graphics received?

A: The response was overwhelmingly positive. The NBA’s production team, event organizers, and even sponsors were thrilled with how everything turned out. Many of them complimented us on the vibrancy of the graphics and the attention to detail. It was extremely rewarding to see our work make such a strong impact at such a prestigious event.

Q: What lies ahead for VIVAS Inc.?

A: This project was a testament to the strength of our team, the preparation we’ve invested in, and the experience we’ve gained over the years. Being able to meet the demands of such a large-scale event on short notice reinforced the importance of having a solid workflow, the right people, and high-quality equipment. This opportunity has pushed our business to new levels, and we’re excited for what’s next!

Q: What was the timeline you were working with?

Q: What was the timeline you were working with?

Q: How were the graphics received?

Q: How were the graphics received?