To borrow a line from a 1970s mega hit from REO Speedwagon, “So if you’re tired of the same old story, oh, turn some pages,” meaning it’s time to move on and start something new. Such is the case with roll-to-roll printing, which offers users the flexibility of “rolling with the changes” in an ever-changing market, as well as giving them the option of trying things a little differently when planning out a wide-format signage project for a client.

Roll-to-roll printers provide a plethora of options for shops; they are like having a Swiss Army knife on staff. These machines produce incredible quality at high production speeds while providing the versatility to produce everything from vinyl and canvas banners to backlit signs and vehicle wraps.

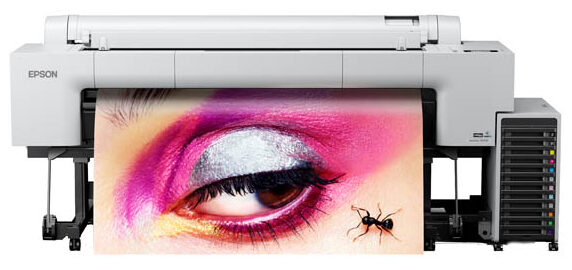

Marc Aguilera, product manager at Epson America in Long Beach, California, added that one of the big trends in this area is the expansion of roll-to-roll to other large-format printing categories, such as aqueous pigment printers. “For example, Epson is offering more options for roll-to-roll printing with its SureColor P-Series aqueous printers with 24″ and 44″ options with built-in dual roll take-up systems, as well as options for 64″. Our customers who are leveraging this roll-to-roll printing — regardless of the type of printer they are leveraging — see huge productivity gains, due to the continuous feed mechanisms. This allows for faster throughput and reduces downtime associated with media handling and allows print shops to print unattended and fulfill orders more quickly, meet deadlines, and increase their overall production capacity.”

Aguilera also points out that recent updates to roll-to-roll printing include a built-in dual roll system, which allows users to load two different rolls into the printer at once and auto-switch between rolls depending on the print job. “Dual roll systems enable varied print jobs back-to-back without manual intervention, providing flexibility to produce a wide range of products without extensive reconfiguration as well as optimize media use to reduce waste and improve inventory management. With the dual roll system, one roll in the dual roll system can be set up as a take-up for roll-to-roll printing, with the inside or outside roll winding directions,” he explained.

Optimizing equipment

“The throughline for everyone involved in wide-format display graphics printing is productivity: how can a print service provider optimize their equipment and workflow to enable more sellable square footage, with fewer human touchpoints, while maintaining exceptional quality output? This question is true regardless of printer type, whether using an eco-solvent, UV-LED, or transfer sublimation printer,” noted Timothy Mitchell, senior manager of customer experience at Mimaki USA in Suwanee, Georgia.

Mitchell says offering a print technology that will support a wide versatility of applications is something he feels UV-LED does exceptionally well. “Nothing supports the breadth and depth of application variability like our roll-to-roll UV-LED printers arrayed with white and clear inks; you can print almost anything you can imagine and on almost any substrate.” He also sees continued movement towards addressing sustainability issues, whether in energy usage, consumables, and labor optimization, or in-line and post-use recycling and recovery.

Advantages of roll-to-roll

Epson’s Aguilera noted that roll-to-roll has many advantages in production. “Instead of printing a job and cutting the roll, the printer can print several jobs and wind up the jobs onto a core, then when ready, remove the core and use a cut system to process each individual job. This greatly increases production by continuously printing for long durations of time. The roll-to-roll system also allows for unattended printing.”

He continued, “For large-format aqueous pigment printing, a roll-to-roll system allows for high-volume photographic and graphic art applications. Particularly within photographic printing, we’ve had customers tell us that by moving to a roll-to-roll system, it has greatly increased productivity. It also allows them to use the printer for what it’s designed to do — printing; and use a cutter for what it’s designed to do — cutting.”

More media options

Daniel Valade, Roland DGA product manager of digital print in Irvine, California, feels that the biggest advantage a roll-to-roll printer or printer/cutter offers is maximum versatility. “They can use a wide variety of media that comes on a roll, including vinyl, banner material, canvas, fabrics, film, and many more. This versatility enables the print provider to accept many different types of jobs, allowing for a larger customer base and greater profitability.”

“Additionally, roll-to-roll printers like our TrueVIS VG3 and SG3 eco-solvent, LG and MG UV, and AP-640 latex models offer excellent print speeds and can accommodate large rolls of media for continuous, uninterrupted printing. Plus, they are reliable, low-maintenance workhorses. Multiple prints can be produced simultaneously, and larger jobs can be completed quickly and easily — you can even let your roll-to-roll printer run unattended overnight and expect consistent, high-quality output when you return to the shop in the morning.”

Valade points out that roll-to-roll printers are extremely versatile machines that can handle a wide range of applications. “The Roland DG TrueVIS family also offers a choice of roll-to-roll inkjets that use differing ink types — eco-solvent, UV, and latex — to meet varying user needs and preferences when it comes to applications.”

He recommends eco-solvent printers/cutters like the Roland DG TrueVIS VG3 and SG3 models as they are great for producing everything from signs, banners, and POP displays to labels/decals, window graphics, and vehicle wraps.

Valade explained, “An advanced UV roll-to-roll model, such as those in our TrueVIS LG and MG series, are also ideal for many of these same applications, as well as for packaging prototypes/short-runs and producing textured wallcoverings. In addition to delivering unsurpassed image quality, these roll-to-roll UV printers make it easy to incorporate stunning three-dimensional and textural effects into their prints.”

“Our TrueVIS AP-640 resin roll-to-roll printer can also handle a wide variety of applications, but they’re especially well-suited for creating vehicle graphics, wallcoverings and floor graphics, interior decor, fine art reproductions, labels, and stickers. Because they use environmentally friendly inks that are water-based and GREENGUARD Gold certified, the wall and floor graphics produced can be used in health-sensitive settings like hospitals and schools. Another advantage is the fast-drying time, which allows vehicle wrap shops to laminate quickly with minimal outgassing,” he said.

Extreme versatility machines

Mitchell believes both roll-based and flatbed printers offer value to wide-format display graphics print service providers, and their extensive portfolio reflects that sensibility. “If we look at some of the advantages unique to the roll-based printers, that answer is best expressed as extreme versatility. Roll-to-roll can print on nearly any media that’s packaged on a core including vinyl, banner materials, certain fabrics and canvas, films, and more. They can also be deployed to produce nearly any print project, even if the final substrate is rigid as flexible media can be trimmed and applied to a rigid substrate. Adhesive roll can always be mounted to boards, even if it isn’t as efficient as printing directly.”

Mitchell noted that the primary applications for eco-solvent and UV-LED roll-based printers continue to be signage and graphics for POP displays, event signage, exhibit graphics, window clings, decals, labels, vehicle wraps, day/night graphics, floor graphics, etc. “Durability is still very good with eco-solvent inks, and they are excellent at reproducing color, particularly on translucent vinyl materials. Mimaki eco-solvent printers are widely used in vehicle wraps and outdoor banners. UV-LED inks are equally durable but add the advantages of opaque white ink along with clear ink embellishments for every type of layering application. UV-LED is perfect for decals, wallcovering, window and floor graphics, and traffic applications.”

For transfer sublimation printers, applications (excluding apparel) encompass soft signage such as hanging signs — ubiquitous at any exhibition worldwide — plus tension fabric signage, SEG frames, flags, wind dancers, and POP displays, said Mitchell. “However, print service providers aren’t limited to soft signage applications. For example, transfer sublimation can produce graphics on hard surfaces such as metals, plaques, glass, and specially coated panels for industrial decor.”

Mitchell sees features being added to produce consistent high-quality output, which reduces or eliminates the need for unbillable repeat prints. “Additionally, we see functionality improvements that enable print service providers to offer more versatility (in terms of deliverables) from a single unit.”