UV-LED Versus Sublimation

What's the difference between the two digital decorating technologies?

UV-LED is similar to sublimation in the fact that it is a digital printing inkjet technology. Graphics are designed in a similar fashion as sublimation without many color limitations, and color matching is handled in much the same fashion as sublimation.

One big difference between UV-LED and sublimation is that once the image is printed and immediately cured with the UV-LED light, the product is finished. There is no need for a heat press to apply the image to the final product as in the sublimation process.

Another big difference is that when you create an image for sublimation, you are thinking about the design in a single-layer process. UV-LED images are designed with a multi-layer thought process. UV-LED printers generally have CYMK four-color ink set along with a white and clear ink. The CMYK ink set allows you to create the digital color images.

Having the white ink component allows you to print a base coat of white ink underneath the color image. This is needed when you may be printing to a clear or a dark substrate. With the white component, you can also print to the backside of a clear substrate, and print the white component on the backside of the color component so that the color shows up when viewed from the other side of the clear substrate.

The clear component to UV-LED allows you to print a clear coat over your image to give it more durability, as well as a glossier appearance of your finished image.

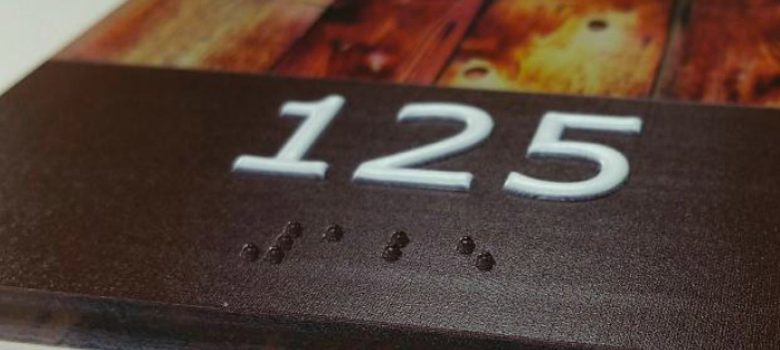

When you are printing with a UV-LED printer, many of these layer functions can be printed at the same time. Also, with the ability to print layers, the UV-LED printers can build up layers of ink to give the finished print texture-the print will literally rise off the surface of the substrate. Using this function allows the UV-LED printer to start with a flat substrate and print enough texture to be able to digitally print completed ADA signage along with printed ADA-compliant Braille signage.

Another difference with UV-LED versus sublimation is that you can only sublimate onto poly materials. UV-LED can print to a large array of materials, but it is recommended to use an adhesion promoter to prep the surface for the adhesion of inks to the surface of the substrate.