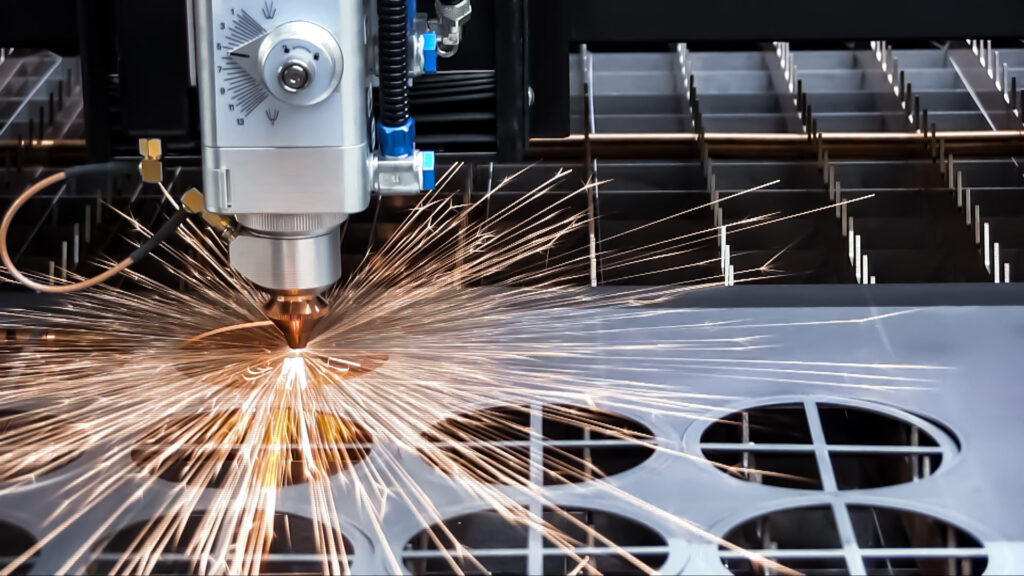

Large-format lasers allow shops to customize any size and shape of wood, rubber, metal parts, and more. You may have thought about taking the leap from a smaller laser to a bigger one, but when is it the right time to make that commitment? There are several components a shop must consider, such as power requirements, space, the expansion of inventory, and maintenance.

But first, what qualifies as a large-format laser? The main difference between traditional and large-format laser equipment is the size of the system, says David Stevens, Trotec Laser. The larger the system, the larger the application can be.

Kern Laser’s Derek Kern refers to equipment as large format when the laser bed is 52″ X 50″ and larger. In general, these larger table sizes do not come in an enclosed desktop format, as you typically see with smaller systems.

According to Stevens, large-format machines provide accurate, efficient, and broad capabilities like any flatbed laser system. These laser machines are ideal for businesses that work specifically with large-format textile, acrylic, film and foil, and other cutting applications. Large-format laser systems can provide high-quality results with expansive working areas and more power.

Qualities of large-format lasers

Large-format machines make it possible to laser engrave and cut industry-standard sheet stock such as plywood, MDF, plastics, and more. According to Stevens, large-format lasers are typically offered in higher wattages for thicker material cutting. “More traditional laser systems hold the advantage of faster processing speeds due to the smaller, lighter motion systems when engraving and/or cutting thin materials,” says Stevens. “It is becoming more common for laser manufacturers to offer both types of laser systems to accommodate their broad customer range.”

The end uses and applications of large-format lasers can include large-scale photo engraving, LED edge lighting, headstones, and furniture. Mandi Smallwood, AP Lazer, says it allows funeral/monument companies to add a special touch while engraving a casket or adding a photo to a monument. It is also beneficial to sign shops and woodworkers, according to Smallwood. Sign shops can fabricate larger outdoor signage, while woodworkers can personalize furniture that would not fit in a box top laser, such as a large live-edge table or a stool.

The main benefit of large-format lasers is not being limited by the size of your laser, Smallwood adds. With large-format systems, “You are able to engrave something as small as a peanut to as large as a 10-foot monument or bigger,” says Smallwood.

“Large-format machines utilize many of the same easy-to-use software’s that other smaller desktop models use,” says Kern. Additionally, Kern says large-format lasers have high yields and low system downtime. “Lasers have a thin cutting kerf which allows parts to be nested tightly together, maximizing the sheet yield,” Kern explains. “The system naturally needs to be touched less often versus a small-format machine. Material loading and unloading is performed less often due to the large sheets the machines can accommodate.”

What to consider when upgrading

A few factors play a role in upgrading or purchasing a large-format engraver. “One would be if you’re looking to increase production and do more items at one time in a large bed,” Smallwood says. “Another would be having the capabilities to engrave anything you can imagine.”

The point at which it is best to upgrade can vary from application to application, Kern says. “It is important to not only look at it from a number-of-parts to produce aspect but also from a quality side.”

Stevens says to consider the following before investing in a large-format laser:

- What’s your biggest material size when processing sheet stock?

- How large are your production runs?

- How do you want to use your laser, and how much laser power is necessary?

The size of your material determines the size of the laser machine that you will need, but batch size may also be a factor. For example, if you are processing a large order with multiple parts, they can be processed in one job with a larger working area, saving time, and increasing productivity.

“The most important criteria when selecting the power of your laser machine is the primary application you will process most frequently with the laser,” explains Stevens. “If the laser is mostly used for engraving, you will achieve good results with laser powers between 25 and 80 watts and will not require higher power.” For laser cutting or high-speed applications, Stevens recommends a laser power of more than 80 watts.

“Every laser varies between type, model, and manufacturer, so make sure you not only have the space for a large piece of equipment, but also the electrical and ventilation requirements,” says Stevens. With higher wattage options comes higher power requirements. Stevens explains, as a rule of thumb, any CO2 system over 100W will typically require a 220V supply as compared to a 110V.

Most large-format machines are available in several electrical configurations that are common in more industrial type buildings, including 230V/single-phase, 230V/three-phase, and 460V/three-phase, Kern adds. When upgrading to a larger system, Kern suggests asking your salesperson about processing bed variations.

Every material acts differently, and the cutting bed, whether it is acrylic slat bed, aluminum honeycomb, or another metal structure, can deliver benefits to your end product. Additionally, make sure to keep enough room around the machine to not only accommodate the operator but to also load/unload and perform the maintenance operations required on the machine.

Making the most of a large-format laser

Shops can make the most of their large-format investment by taking advantage of the size and capabilities, says Stevens. “Since laser processing is extremely versatile and allows you to process a wide range of materials, consider expanding your business into new industries.” For example, if you previously focused on producing B2B signage and finishing for displays and print materials, you can consider incorporating B2C (business-to-consumer) applications such as personalized signs and wall decor.

Additionally, investing in proper training is worth it, according to Kern. “Not only should your operators learn how to use the machine properly, but they should have in-depth application training,” Kern says. You can also refer to your laser company as the sales teams consist of knowledgeable experts in the laser industry.

“You are able to engrave anything you put your mind to, minus a few hazardous materials,” concludes Smallwood. “Get the word out in the community what you are capable of and let the customers bring you their ideas, and you bring them to life.”