Try This: UV Print Full-Color and Textured Elements Directly on Plaques

Offer your customers something different than the traditional plaque.

UV printing is a great option to add full-color images to a variety of products, including plaques. Offer your customers something different than the traditional plaque by following these steps.

Materials Needed:

- Wooden plaque(s)

- UV printer (this project uses the Direct Color Systems 1800z; always consult your manufacturer’s instructions when setting up and completing a UV printing project)

- RIP software (many are included with the printer package)

- Silicone tacky mat

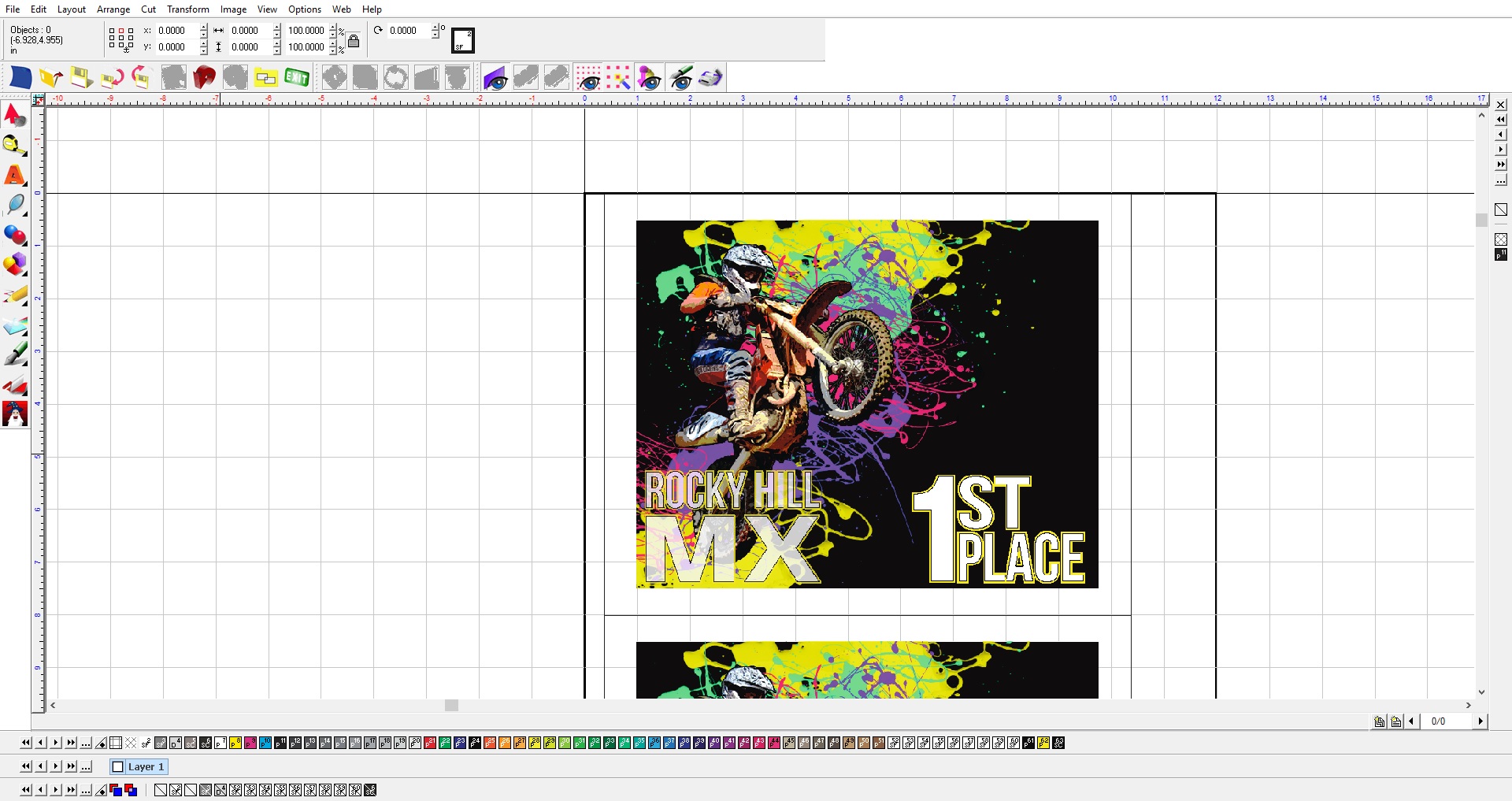

Step One: Design Art File

Step one. (All images courtesy Michael Perrelli)

Create your art file. For this project, we have the white areas receiving the most “lift” or texture, color heights will vary based on the darkness of the color, and the black areas will be flat. Don’t worry, that isn’t set in stone. The operator or designer can easily adjust any of these areas in the software if needed. There will also be a white underbase that is printed under the flat areas (simultaneously) to provide the highest quality output, color saturation, and opacity.

Step Two: Load Products onto the UV Printer

Step two. We recommend using a jig if you plan to print large quantities of the same item.

If producing large quantities of the same product, we recommend a jig or fixture that can be easily loaded and unloaded. For small runs (or in the case of this project), the operator can simply print an outline of the product’s shape from the art file in step one onto the silicone tacky mat. This ensures accurate placement of the product on the printer’s bed. Once the job is complete, the silicone tacky mat easily wipes clean.

Step Three: Print the Plaques

Step three.

Send your art file to the RIP, select the appropriate print mode (in this case, Texture), right click on the job, and select PRINT.

Step Four: Remove Printed Products from Printer

Step four. The UV Printing process is fairly simple and quick.

Once a product is printed with the UV printer, it is ready for packaging, mounting, or further fabricating. Simply remove the printed products and reload the next set. If printing the same art file again, step one can be omitted from the printing process.