Face shields are in high demand and some of our customers are shifting production of their laser systems to help fill this need.

Here is a simple design for a face shield that can be produced quickly with a laser system.

Overview

Face shields of this type are sometimes called splash shields because they are designed as a supplemental barrier for liquids and not for impact protection. By themselves, face shields offer limited protection. These face shields/splash shields are coupled with N95 masks as part of a personal protective equipment (PPE or P.P.E.) plan. For this reason, face shields are considered adjunctive or supplemental personal protective equipment.

Required Parts

There are many different designs for face shields but the common elements are:

- Clear plastic shield that covers the face including mouth and eyes

- Material between forehead and clear shield creating enough space for a nose, facemask and glasses (typically plastic or foam)

- Method and material to hold the mask on the head (typically a strap, band, or cord)

Design Materials, Details, and Dimensions

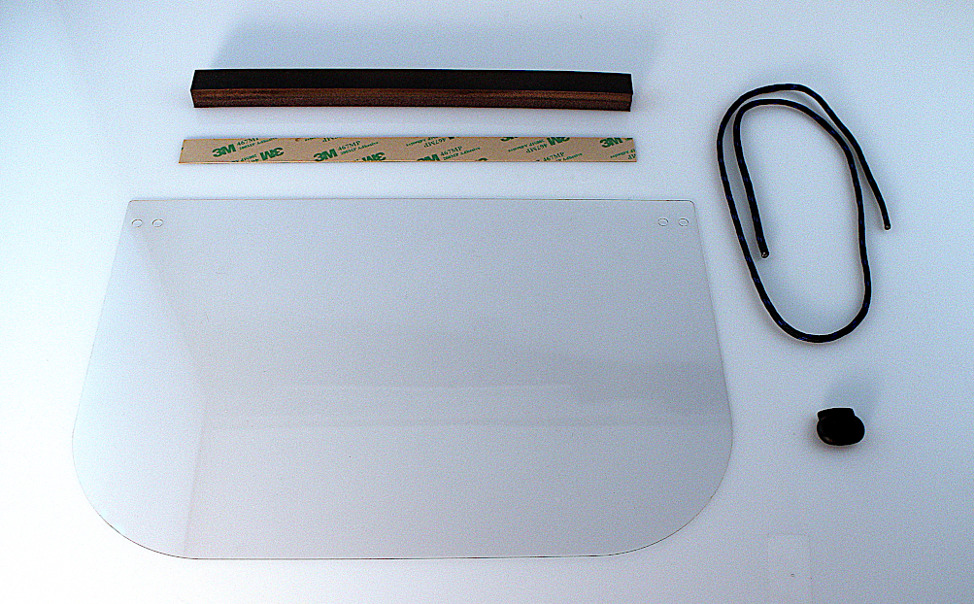

Plastic sheet —12″ wide X 11″ high for the tall shield. The standard shield is 12″ wide X 8″ high. (All images courtesy Universal Laser Systems)

Foam and adhesive — 10″ wide X 3/4″ high. Foam is 1/2″ thick.

Paracord — standard diameter of 5/32″ and length of 28″.

Cord lock

For face shield construction we use:

- Thin and clear flexible plastic sheet (polyester film/PET/PETG or polycarbonate/PC) — Clear film .010″ to .020″ (no part number).

- Closed-cell foam approximately 0.50″ to go between forehead and clear plastic sheet — Rogers Corporation 4701 Poron closed-cell urethane foam

- Adhesive to attach foam to plastic sheet — 3M 467MP high-performance adhesive transfer tape

- Paracord (nylon cord) to hold shield onto head — 550 Survival Paracord, Type III Commercial Grade (any color)

- Plastic cord lock for adjusting cord length to adapt to different size heads — Plastic Cord Lock End Toggle – Double Dual Hole Spring Stopper Fastener Slider Toggles End, 16 X 17mm, Q2691

Substitute materials:

- Available closed-cell foam and adhesive — We specify closed cell foam because it does not absorb moisture. There are many suitable foam materials from a variety of manufacturers available in sheets. Foam is also available in rolls with adhesive already applied.

- Elastic straps instead of paracord — The plastic sheet and foam curved around the front of the head act like a spring and create enough tension with the paracord to hold the face shield firmly in place. Paracord with a plastic cord locks is infinitely adjustable. You can substitute an elastic strap but then you need to find a different way to attach the band to the shield and need to consider other variables including head size, strap length and strap tension.

- Acrylic and PVC plastics — Do not use acrylic or PVC. Avoid acrylic because it is brittle and scratches easily. In addition, alcohol used for cleaning and sanitizing quickly cracks acrylic. Do not use PVC. In addition to it not being rigid enough, laser cutting creates toxic chlorine gas that is hazardous and also corrosive to laser system parts.

Laser Processing and Face Shield Assembly

The fabrication of all parts for a face shield requires just one process – laser cutting. Laser marking for part number, logo, website or other purpose is optional and can be done directly onto the shield material.

- Plastic sheet cutting – Laser cutting the plastic sheet can be accomplished by any Universal Laser System with a CO2 laser. Time will vary with machine and laser power but is typically less than a minute. Polycarbonate is superior for impact resistance, but these shields are for splash protection so most shields of this type are constructed of lower cost and faster processing polyester film (PET/PETG). Keep the factory masking on the material or add masking before cutting to keep the material clean.

- Foam and adhesive cutting – Foam and adhesive can be cut separately or the adhesive can be added to the foam before cutting.

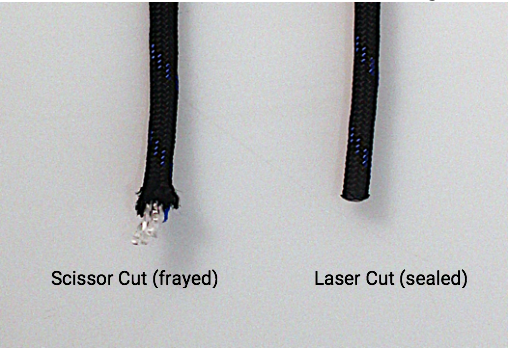

- Paracord cutting – Laser cutting is highly recommended for Paracord. Paracord consists of a woven tubular nylon sheath surrounding dozens of individual nylon filaments and strands. When mechanically cut it frays. With laser cutting, the ends are automatically heat sealed so there is no fraying.

Assembly consists of attaching the foam strip to the shield with adhesive, sliding the cord lock over the cord, and tying the cord to the left and right side of the shield.

Laser System Considerations

Laser processing for face shields is possible with all laser systems equipped with a CO2 laser.

- Processing area – A larger laser system has the advantage of less material preparation (cutting down to size) and fewer laser system loading and unloading operations.

- Laser power – The minimum power for cutting the materials for a face shield is 25 watts. Productivity increases with an increase in available power up to 150 watts.

- Gas assist and optics protection – Gas assist using an air source is a standard requirement for cutting operations. Optics protection integrated with the gas assist protects laser system components from debris created in the cutting process.

- Cutting table – A cutting table helps keep material clean especially if the material is unmasked. With a flow-through design a cutting table also helps hold down thin materials including the plastic and adhesive sheets.

Note: this article originally appears at www.ulsinc.com/resources/uls-blog.