Sign and graphics shops are more than the sum of their parts. Yes, printing equipment and heat presses are important, but to be really successful in printing, apparel decoration, and car wraps, it is important to stock up on these essential tools.

Tools for car wrap installation

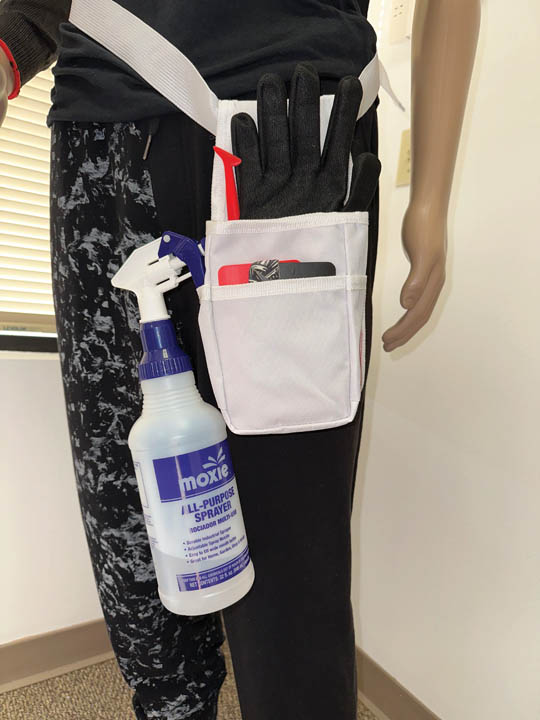

PROSERIES in Jacksonville, Florida, has made a name for itself in the car wrap industry by creating a line of essential tools, everything an installer would need to start wrapping cars, minus the vinyl, said Austin Smith, CEO of PROSERIES. It also offers training classes for installers.

The company’s main line of tools includes gloves, which are “not only a way to maintain your hands as far as getting cut or dirty throughout the process, but most importantly, pushing air out from the vinyl,” he said.

A 4″ squeegee can be used to smooth out the material while the installer uses their hand to push with their palm or work it into tighter spaces with a finger. Gloves allow nonfriction contact to the plastic or paint protection film (PPF) base, he added. They “allow you to seamlessly slide down the side of a car, from the top of the pinkie to the bottom of the palms as they push down the channel. They allow you to touch the sticky side of the vinyl, grab the edge, and pull it tight to get it on the car.”

Without the gloves, the vinyl would adhere to the installer’s fingers.

Buffers are a popular tool. These thin adhesive-backed felt pieces are mounted to squeegees and serve the same purpose as gloves. The wet and dry buffers allow installers to use a squeegee to work the material into different areas on the car or apply graphics to substrate boards or other surfaces being mounted with vinyl. Firmer buffers can be used on any dimensional object, including vehicles. Softer buffers work well for applying graphics without damaging the print. Buffers are an inexpensive option to lengthen the life of car wrap squeegees.

Knives and blades are important for cutting wrap material with surgical precision. Installers don’t want to use dull knives that will drag along the material rather than cut, Smith said. That’s why his company offers a 45-degree snappable blade. Tuck tools are also a must. They allow installers to work material into tight places.

Nonessential tools include thick foam mats, so installers don’t have to kneel down or lie on cold concrete floors while working on car wrap installation. Another nice-to-have is a U-shaped tool that vinyl is draped around to help workers install it around car antennas or mirrors.

PROSERIES also makes an arm sleeve, which is made out of the same material as its gloves, to help protect an installer’s arms when reaching around doors. It also protects arms from the sticky adhesive on the back of the wrap material.

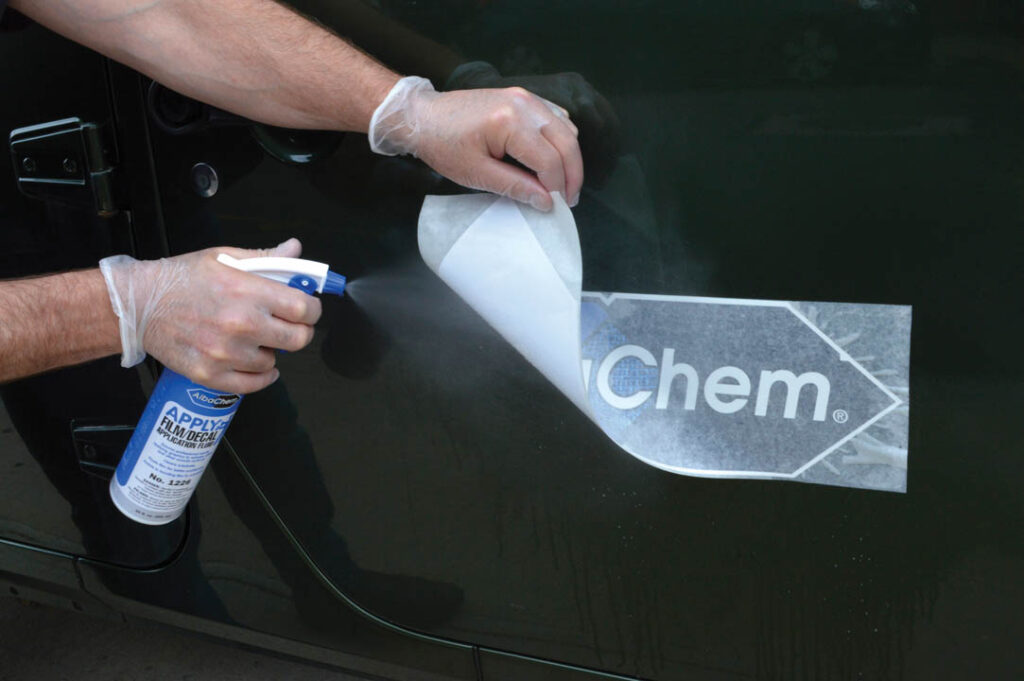

Albatross USA, maker of AlbaChem products, offers several liquid adhesives, lubricants, and cleaners that can help shops apply vinyl lettering to signage or ease the application of car wraps. Application fluids for cut vinyl can go on signage and cars. It is sprayed onto substrates, allowing the installer to float the graphic into position.

In the past, installers would use soap and water, which does work, said Barry Bravman, VP of sales and marketing for Albatross USA, but using an application fluid helps the adhesive bond better to the substrate.

Adhesive remover can be used to remove adhesive that is left over from prior vinyl applications. Shops that want to remove old graphics and install new ones will use a liquid removal tool to get the job done.

Tools for decorated apparel

When you think of tools, it calls to mind things that are tangible, that you can see and hold in your hands, but one of the most important shop tools is chemical solutions that aid in applying graphics or removing them. Solutions are also used for cleaning screens or spot cleaning apparel when rogue ink splotches or grease spots appear where they shouldn’t.

In screen printing, several basic chemicals are a must, from cleaning agents to degreasers. Screen printing shops typically have a lot of ink floating around, and many times, unwanted ink will get where it isn’t supposed to be, Bravman said.

“A printer may have ink on their hands while printing shirts and all of a sudden get smudge marks where they held the shirt,” he said. Another common occurrence is a pinhole in the screen being used to stencil a graphic onto apparel. If no one notices the extra dab of ink, several shirts could be contaminated.

Spot cleaning guns will push cleaning fluid onto the spot at high pressure, which pushes the ink through the fabric to clean the shirt, he said. “It is used on cured ink, not uncured ink. It works better after it goes through the dryer; otherwise, it will hit the ink and bleed.”

Commercial embroidery shops often need to remove oil stains that come from workers over lubricating their equipment. Spot cleaning guns or aerosol products can also be used to remove oil stains.

Once Albatross got into heat transfer vinyl, it came out with a vinyl remover for fabrics. Individuals who cut vinyl sometimes make mistakes that need to be removed and replaced. This remover is designed to attack the binder that allows a direct-to-film (DTF) graphic image to be peeled or scraped away. This solution is designed to be washed out. It needs to sit on the fabric for a longer period of time, making it easier to remove the adhesive residue after the graphic is taken away.

The value of these tools is not only to save the cost of the garment, whether it be a T-shirt, hoodie, or hat, he said, but the most important benefit is allowing decorated apparel producers to fill orders on time because “a lot of time these businesses don’t have a warehouse full of blanks to pull from to pull another shirt should they make a mistake.”

He added that “whether to save a garment or spend time and money to clean a garment is really in the eye of the beholder. They have to make a judgment call.”

It could take 15 minutes to clean up adhesive, ink, or oil stains, but in an industry such as screen printing where a little bit of ink can travel outside of the design, it is imperative to have spot-cleaning tools on hand. Those stains have to be cleaned quickly, and these tools help a shop do that.

“From a production standpoint, it makes a lot of sense,” Bravman said.

Albatross also manufactures screen cleaning products, screen openers, and screen washes. A screen opener can be used on the press when a clog stops the ink from moving through the screen. Shops will spray this liquid onto the screen and wipe it off, which opens it up to continue printing. The fluid is also used to clean screens between color changes so shops don’t have to change the registration, he said.

Platen adhesives are used to keep T-shirts from shifting as they are being printed.

Emulsion is used to coat screens so that they are photo-sensitive. Shops then take a film positive and put it on the screen before exposing it to UV light. The screen is then washed out with water.

“Everywhere the image was will wash away. That leaves where the ink is going to go through the screen onto your shirt,” said Taylor Landesman, VP at Lawson Workhorse Products in St. Louis. “You do that for every color.”

There are three standard screen sizes, 20″ X 24″, 20″ X 28″, and 23″ X 31″. The two larger sizes are used for automatic screen-printing equipment. The 20″ X 24″ screens are for manual presses. As DTF printing rises in popularity, so has the industry’s move to embrace automatic screen-printing equipment.

“People that were printing manually tend to go DTF now,” said Landesman. “Not to say that no one is doing manual printing, but more people are doing DTF now than manual.”

DTF printing uses PET film instead of vinyl. To get into DTF, shops need a printer, adhesive powder, and a heat press. Commercial shops typically invest in an automatic powder shaker to make the printing process go more smoothly, he said.

For direct-to-garment (DTG) printing, shops need a printer, a heat press, and a liquid pretreatment that is sprayed onto the garment to allow the print to remain on top of the fabric. Pretreatment can be done by hand, or shops can purchase a dedicated pretreat machine. DTG is more limited than DTF or screen printing when it comes to the types of fabrics it can be applied to. DTG only works on 50%-100% cotton garments.

“DTG was really popular when it came out 10 years ago. It is much less popular now that DTF is around,” Landesman said. “DTF is definitely more popular than DTG printing because of its ease of use; it goes on anything.”

Other accessories for DTF that are nice to have but not essential include automatic cutters that cut out printed heat transfers and machines that will heat press and apply the transfers.