It’s true that for any piece of equipment that’s used every day in a high-volume environment, the better it is maintained the better it will perform and the longer it will last. This is especially true for wide-format printers. It is crucial to keep your wide-format units properly maintained to ensure the high-quality output on a continuing daily basis. Here, some experts in the field take a look at the importance of proper maintenance and offer some sound advice on how to keep your printers running at full capacity.

Read the Manual

“Keeping your printer well maintained and following the recommended cleaning and maintenance schedules outlined in the owner’s manual for your specific machine is crucial,” says Juan Molina, Roland care manager at Roland DGA, Irvine, California. “It’s not only crucial for optimum performance and output, but also when it comes to extending the life of your printer.” He notes that each Roland printer user manual-specific to each model-provides all the information you need to perform proper maintenance on your device.” Hard copies of these manuals and digital versions are available at the Roland Care section of the Roland DGA website.

“Additionally, Roland-certified dealers are thoroughly trained to assist end users when it comes to establishing and maintaining a regular and effective maintenance routine,” he adds. “There are also useful videos and webinars available for viewing at Roland DGA’s YouTube.com page.”

Maintaining Printheads

Richard Martinez, technical service support for Mimaki USA at the Corporate Tech Center in Suwanee, Georgia, says that maintaining the printheads is the most important thing on a digital printer. “This why it is important that the capping station be adjusted correctly when it is installed and that the proper daily/weekly maintenance be performed by the end user. A lot of times problems arise because the maintenance is not being done.”

He adds that the environmental conditions that the printer is in can also be important when it comes to maintenance. “In both the installation and the operator’s manuals are guidelines and instructions on how and where the unit should be set up. The major items mentioned are that the printer should be in a controlled environment where the temperature, relative humidity and power meet the required specs needed. It’s also important is that the floor is level and strong enough to keep the printer stable, and that there is no direct sunlight on the unit. Also, make sure the HVAC system does not blow directly onto the printer.”

Martinez explains Mimaki printers include a sheet that can be placed by the printer explaining the proper daily/weekly maintenance requirements for the unit. “This information is also in the operation manual. These maintenance procedures should be explained by the dealer tech to the end user when the unit is first installed. These procedures only take about 5-10 minutes per day to complete.”

Keeping the Printer Clean

Jason Stone-tech services manager at Salt Lake City-based Regional Supply, a distributor that repairs and performs maintenance on printers-says that one of most important maintenance issues to consider with wide-format inkjet printers is keeping them clean. “I can’t stress this enough,” he says. “I can’t tell you how many times I have gone out on a service call that could have been avoided if the customer would have just simply kept their machine and the environment clean. Taking the time once a week or once a day, depending on how much you use your machine, to thoroughly clean your machine can save you thousands of dollars on costly repairs in the future.”

Stone says shops should make it a priority to clean around printheads, cap tops, and wipers once a week or daily. “This is done with a cleaning solution (specific to your inks) and a swab or lint-free cloth. If you have a large build up of ink around your printheads at some point that ink is going to drip off and ruin your print, or a piece of lint will stick to the ink and cause smear marks in your prints.”

Cleaning Printheads

Stone points out that different printheads require different cleaning procedures. “Most solvent printheads you only want to use a swab and cleaning fluid to wipe around the printhead and never the bottom of the print head where the nozzles are. You risk permanently clogging nozzles if you do so. On the other hand some UV-cure printheads require you to wipe the bottom of the printhead to clean the nozzle plate. You do this with the proper cleaning solution and a lint-free cloth. Aqueous printheads can be cleaned with distilled water.”

Stone agrees that cap tops are often overlooked when performing maintenance. The cap tops are rubber boots that seal the printheads and help keep them from drying out and clogging. Using the proper cleaning solution on your cap tops keeps the rubber from drying out which can prevent them from properly sealing with your printheads. Many printer manufacturers recommend replacing your cap tops periodically.

He adds that wipers are another part on printers that often get overlooked. “These should be cleaned as part of your maintenance schedule and replaced when worn out. Also check the area around your wiper or wipers. Many times ink buildup around wipers, especially on the rails they ride on, can cause issues with your printer. If your wipers don’t move like they are supposed to, the printer will give you an error code and you will have to pay for a service call.”

Keep the Environment Consistent

Stone says that shops also need to keep the printing environment consistent. “If you have drastic changes in temperature and humidity you will see inconsistency in your prints in color and image quality. Humidity is very important for your printer. I live in Utah, which is a desert with very low humidity. Because of this we see a lot of issues with static. Static can cause the ink to do weird things and if static gets too bad you can fry the printer’s electronics, which can be costly to repair.”

He points out that different printers require different levels of maintenance. “Some printers, like the new HP Latex printers, perform a number of automated maintenance tasks; and others require that you to physically clean the machine. Also, depending on the ink you are using you may have to clean your machine more often.”

Stone also notes that solvent inks dry quicker and need to be cleaned more frequently than water-based inks. “Some UV-cure printers use white ink which has a heavier pigment, and these inks need to be agitated frequently so the pigments don’t all settle to the bottom of the cartridge. It is always best to refer back to your printer manufacturer’s user manual for the recommend maintenance to perform on your machine.”

Keep Things Simple

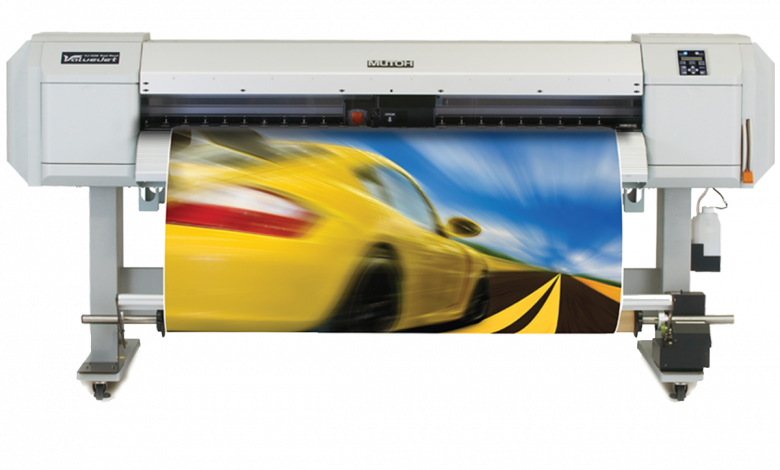

David Conrad, director of sales and marketing at Mutoh America, Phoenix, Arizona, notes that some frustrating issues such as banding, missing nozzles and nozzles coming and going are all possible outcomes of lack of maintenance. “Simple maintenance procedures are typically described in most printer manuals. The problem is that many users do not read the manual. That being said, there are also many good YouTube videos that can assist the printer operator in developing a good maintenance habit.”

He adds that cleaning the capping station, running a nozzle check and perhaps executing a nozzle purge are simple techniques to ensure a better print outcome. Conrad explains that these things are simple to accomplish and take very little time away from production.

Replacing Consumable Items

“Many times, users talk about banding or ink dripping on the image or other effects all of which can indicate a need for maintenance,” says Conrad. “Replacing consumable items such as maintenance stations, dampers or filters-if your printer requires them-before they go bad and on a scheduled timeline will allow end users to control their downtime vs. the machine going down when they really need it. Simply cleaning the capping station and performing a nozzle check regularly can be a huge positive action in keeping your printer running smoothly.”

He recommends developing a daily, weekly, monthly and yearly approach to preventive maintenance. “Place a written schedule of what should be done regarding maintenance on a wall near the printer and execute them as if it would cost you thousands of dollars if you didn’t do them-because it actually could. A well-maintained machine could be the difference between getting that huge job out on time and keeping your customers happy or having a premature failure due to lack of maintenance and not being able to meet your deadlines.”

Conrad says the process for different printers can vary between different ink types, but it is really dependent on the machine model more than the ink type. “Many of our Mutoh UV, dye-sub and eco-solvent machines require the same basic cleaning techniques (with different cleaning solutions of course) but if you look at our UV PJ 2508UF flatbed, that is a totally different process because it is an entirely different machine. It is always best to refer to your specific machines manual/manufacture for the proper maintenance procedures.”

Some Models Have Different Needs

Mimaki’s Martinez says that while there may be some minor variations to the daily/weekly maintenance process, the process is essentially the same for all model types regarding the maintenance. “Having said that, there are some added periodic maintenance items that occur for the UV-cure and other sign and graphics models. This will depend on the ink configuration used on the printer and the model type. For example, on Mimaki’s UV-curing JFX200 and JFX500 Series printers, the machines will inform the end user when the degassing module should be replaced (approximately once a year). Also, units that have white inks in them (both eco-solvent and UV products) will also automatically provide a periodic request (once a year) on the printer’s display asking that the operator change the filters in the ink-recirculation system.”

Another example of a periodic maintenance is if the user is using white and/or silver inks in an eco-solvent type product like Mimaki’s CJV/JV 300. If these inks are used, then the printer will recognize this and prompt the end user to do a daily white/silver ink maintenance-remove the ink cartridge and shake it a bit in order to make sure that the pigment is mixed well.”

UV Units Require More Cleanings

Molina reports UV-cure printers tend to require more frequent cleanings and maintenance than eco-solvent models and other printer types, due to the general chemistry of UV inks and the curing process. He says when using UV printers, it’s especially important to be aware of the specific type of material you’re printing on and any special requirements for that particular substrate. “Also ensure that the material is loaded properly before printing. Roland’s VersaUV flatbeds allow you to raise and lower the printhead height for ideal print quality. This also helps prevent over-spraying or misting, which can negatively affect imaging and, over time, cause damage to the printheads.”

He adds that as far as textile printers are concerned, the cleaning and maintenance are very similar to the requirements for eco-solvent inkjets. “Textile printing, however, often involves longer runs, so cleaning between jobs can be even more crucial. As textile printers use water-based inks, be sure to use water-based cleaning fluid (instead of the solvent-based fluids recommended for eco-solvent printers) when performing your regular cleanings,” he concludes.