The Versatility of CNC Routers

Find out about new uses for current technology with CNC Routers

CNC routers have been around for a long time, and, because of that, many people discount them as old technology. But, old technology or not, these machines are very versatile, and sign shops and other businesses continue to find new and creative uses for them.

Routers come in all sizes, from small models used by hobbyists to larger models for building furniture and large, 3D signs. What drives demand for CNC routers is their precision. Higher-end models can cut within 1,000th of an inch on aluminum, MDF, and various sign foams.

Mark Gawor, owner of GRG Group Inc., uses his Computerized Cutters CNC routers to make intricate architectural models of NFL football stadiums, office buildings, resorts, and even oil drilling platforms. His shop uses other types of cutters, like laser cutters, but 85% to 90% of the work is done on a router because of that precision. He makes his models out of styrene, a thin and soft plastic, which will bow and lose dimension on a laser cutter. Because his models have to be precise, Gawor says he needs to use the slower, older router technology to produce the best and most accurate scale models.

“We’ve been doing this for over 40 years. We have figured it out, what works and what is not worth it,” he says.

Because he isn’t running his routers on heavier materials, the spindles last a very long time. He likens his use of a router to someone running a semi-truck to pick up groceries.

“We are not abusing it, but it is accurate. It is running, and it is great, and they are really capable machines. Routers are very underappreciated,” he says.

Gawor made scale models of AT&T Stadium, the home of the Dallas Cowboys, which was built in 2009, college stadiums, soccer stadiums, and Olympics venues.

Carl Ondracek, president of Computerized Cutters, says that most routers offer the same features, but some are better than others when it comes to precision cutting. Ondracek has been building routers for 25 years. All of them are capable of cutting out 3D designs like push-through letters and channel letters.

Channel letters are the most lucrative part of the sign industry right now, Ondracek says. “That’s growing leaps and bounds, and most people out there are using routers to cut aluminum backs and plastic faces. That’s where a lot of the money is,” he says.

He doesn’t see shops getting into specialty cutting as much, but some use their routers to do ADA braille signage. Instead of engraving holes into a sign where plastic balls can be inserted, a router cuts the surface, leaving the raised braille bumps behind.

Others are using their routers to create 2D or 3D molds for thermoform projects.

Computerized Cutters primarily sells routers to the sign industry. The biggest things they use a router for are acrylic letters and name badges.

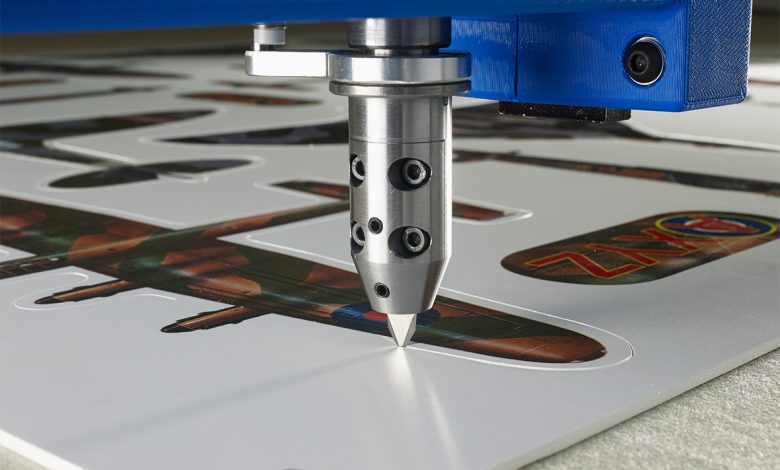

“Routers are so versatile. Most people buy one for one reason and find five other reasons,” he says. For attachments, most sign shops want an engraving head and a tangential knife for cutting materials. Most routers will use a rotating router bit. A drag knife can cut through Coroplast, which are corrugated plastic sheets and other foam products.

Steve Alvarez, Laguna Tools, says that Laguna’s customers use routers to make signs, furniture, cabinets, textured wall panels, plastic and aluminum parts for industrial applications, trade show booths, art pieces, aerospace, car audio speaker enclosures, musical instruments, and custom homes.

“CNCs allow customers to be creative in a totally different way. Anything users can imagine and draw in the software can be machined by a CNC,” he says. “The speed and accuracy of these machines give users the ability to produce parts that are too time-consuming, complex, or expensive to make by hand. By reducing production times, parts become cheaper and faster to produce, allowing shops who own a CNC to increase profits or offer a more competitive price to their customers.”

He says that a carpenter may think of building something by hand, but his process is completely different than working on a CNC router.

CNCs can be used to design joinery or 3D elements that a carpenter couldn’t do with a saw, hammer, and nails. Routers make “these types of shapes easier and allow carpenters to use different joinery methods to create different aesthetics,” Alvarez says. “Once they get their head around how this works and use the software to get the idea into the machine for machining, they kind of open up a huge option for them to do whatever they want.”

Laguna Tools has one customer who uses their CNC router to build wooden bike frames. Another customer makes ornate props for cosplay costumes.

Textured wall panels are becoming very popular, he says. One customer built his custom home with 3D wall panels.

“The house itself looks like a big white wave, and he used his CNC for design elements of the entire house,” Alvarez says.

“Guys are using these in so many capacities nowadays. They are not just limited to wood or plastics. We have a guy in Vietnam who makes entry gates for homes or driveways, all machined 3D aluminum,” he says. “It all comes down to tooling. You buy the right tool for the material you are working with.”

All of Laguna’s routers, lasers, and plasma tables have one thing in common. They have user-friendly controls, so the learning curve isn’t as steep as other systems.

“We like to keep it simple for our customers. We recommend the easiest software that we can, depending on a customer’s needs,” Alvarez says. Finding out what the customer needs the router for, their background, and familiarity with this design software will determine the type of machine needed.

Design trends in the sign industry are always changing.

“A router opens up any material a sign company would ever want to work with. By having a CNC, it gives them the ability to step out of the 2D designs that in the past were what most signs were made of,” he says. Now they can make 3D designs or add 3D elements and aesthetics to their signs.

Larry Daignault, national sales manager for AXYZ Automation Group, says that many of his company’s clients in Los Angeles and Anaheim use their CNC routers to make scenery and sets for movies and television. The company also sells a lot to custom road case manufacturers. These are specialized cases to hold sensitive equipment or musical instruments. The hard outer shell is usually made with wood and aluminum, while the interior is cut with foam.

AXYZ also makes large-format routers for aluminum and metal composite cladding for the architectural and design industry. Many buildings are being clad with aluminum composite material.

The exhibition and display industry is growing quickly, he says. Many companies will manufacture a custom trade show booth for clients who don’t want to take their trailer across the country or overseas for a show. They use routers to make custom stands and tables, backdrops, signage, and cases to hold lighting.

The print-to-cut market is becoming very popular. Once a print comes off a flatbed UV printer, the sign shop can place the design on the router to cut it out.

Cabinetry and woodworking industries use routers to do general and custom woodworking, make furniture and displays, tables, and custom benches.

“We also work closely with a lot of companies that build custom emergency vehicles like fire trucks and ambulances,” Daignault says. AXYZ also works with companies that manufacture travel trailers and motor homes.

AXYZ designs its routers so that they are capable of adding additional tools to the machine, like an automatic tool changer or a vision system, even if the machine wasn’t initially purchased with that capability.