From Etsy stores to sign shops, and from sporting goods manufacturers to medical technology, there’s a HUGE boom going on in UV printing.

Small format UV printer sales are up over 36% so far this year! Yes, even this year, and here are some of the reasons why:

- New lower pricing

- More awareness of the technology

- Lower costs of production

- Seasonal needs

- Situational needs

- New creative applications

The lust for personalization, for customization, and for getting custom products created quickly and precisely is what’s driving those sales.

UV Printer Pricing and the Democratization of Personalization

Just a few years ago, even the least capable small format UV printers would have cost upwards of $50,000. While that amount seems like a steal to those of you that understand the market and the capabilities of UV printing, it’s very intimidating for someone just getting started.

And if you wanted something beyond entry-level, that price would have gone up very quickly.

While a 13” X 19” bed size might not be right for every application, the lower price has more people investigating UV printing. The result is greater adoption of the product.

That level of interest is very similar to what happened with direct-to-garment printing ten years ago. The improvement of the equipment and the lower cost has made DTG a staple now for the apparel decorating industry.

People are Asking if You UV

Awareness of what UV is and does is growing. Because of trade shows and popular industry magazines like GRAPHICS PRO, more and more decorators are learning about UV printing. Awareness is both cause and effect. The more people are interested, the more dealers and manufacturers want to show it. The more the printers get shown, the more awareness.

But the real indicator of a tipping point is that customized product retail goods buyers are starting to ask for it. This is a striking parallel to DTG printing.

When DTG first came out, the public had no idea what it was. Even larger wholesale apparel buyers didn’t realize what DTG would mean for the market. That’s not true anymore—customers are regularly requesting direct-to-garment printing, and that’s starting to happen in UV printing right now.

4 Hot Markets in UV Printing

We looked at customers that have recently adopted UV printing as part of their business over the past six months. We found that the majority fell into four general categories or niches.

So, if you are already in one of these areas with your business, you’re in a particularly good spot to look at UV adoption.

1. Etsy stores are UV printing EVERYTHING

During Episode 129 of the Custom Apparel Startups Podcast, we interviewed Don Copeland, digital product manager for ColDesi, about what’s happening in UV printing. The first and most prolific example he gave was Etsy stores.

That story also provides a great example of the ROI of moving from a manual or less automated process to UV. The company in question was hand-making wooden signs. Assembling slats of wood, stenciling, and then hand-painting them and then building a frame around the outside. Their team was able to produce up to six signs per hour this way.

The motivation for a quick adoption of a UV printer (the Compress iUV1200s to be specific) came when a new seller relationship inspired 1,600 wooden sign orders over a holiday weekend. After switching the production of their custom rustic signs to UV, they went from being able to produce six pieces per hour to 60 in the same time frame.

Gross profit was $30,000, as reported by that customer. It made a massive dent in recouping their investment in the iUV1200s with just the first order.

Of course, this is an extreme example, but people on Etsy are adding UV printers to their businesses every month. Producing and selling everything from rustic signs to Christmas ornaments, Etsy sellers are leading the charge in UV printing adoption.

2. Big brand customization

Big, medium and boutique brands are all trying to do two things:

- Reduce premanufactured inventory

- Improve margins

Since you can use personalization and customization to achieve both of those ends, UV printing has found a prime place.

While companies like Vera Bradley and some home linen brands have been offering monogramming for a few years, the biggest names in fashion and consumer products are just starting to realize the benefits of customization.

The advances in online configurator software that allows a brand to offer the ability to choose from many options and “assemble” their personalized product online have accelerated this process.

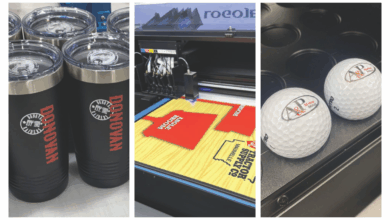

For example, custom travel mugs are incredibly popular, and it’s an excellent application for the right UV printer.

Companies purchase these mugs/cups, manufactured by brands like Yeti and Igloo, from promotional products makers all the time.

What’s happening now is that brands are starting to do this themselves to grab the extra revenue and better their own customer experience, all following the big apparel brands like Nike, Vera Brandley, etc. in the customization and personalization business, but with hard goods instead.

Setting aside the personalization of products, manufacturers are also using UV printing to reduce pre-produced inventory to significant effect. That’s the method of bringing in blank products and adding images to them, rather than preprinted.

3. Apparel decoration businesses

It’s not what you think. We’re not talking about UV printing onto apparel items. DTG printers and other methods are much more efficient and faster on T-shirts.

Apparel decorating—custom T-shirt businesses really—are adding UV printing as a cross-market. Many of our customers grow over time by adding new technology and all the products that they can produce with it. So, an embroidery shop or custom T-shirt printer that already offers customization of apparel is now offering UV printing to fill their customer’s needs.

One reason that expansion has included UV for those shops is versatility. That’s because the same business that comes in to purchase 48 logoed polos, or printed T-shirts probably also want:

- Custom yard signs

- Employee badges

- Recognition awards

- Promo products for leave-behinds

All of which can be printed very quickly on a UV printer. For example, one T-shirt shop that focuses on local schools recently experienced a considerable drop in apparel sales. The schools they service were closed before graduation. Much of that cyclical business was lost, but with a UV printer, they were able to produce graduation yard signs for those same schools and student-customers. That pivot saved their business!

Much of the significant increase in small format UV printer adoption can be attributed to this group of apparel entrepreneurs.

4. Manufacturing and pad printing alternative

UV printing is replacing traditional manufacturing and product marking methods like pad printing in manufacturing. Not in every circumstance, of course, but the idea that manufacturers can personalize or customize products in short runs without the setup involved in older technology is catching hold.

A large sporting goods manufacturer had us testing basketballs and volleyballs, for example. Another will offer custom golf balls with tournament logos, while high-end bicycle manufacturers are putting logos and names on frames, and a custom motorcycle maker applies full-color graphics to cowls and covers. The opportunities are practically endless.

Some are also using them for variable data, including applications like printing UPCs directly onto products or adding serial numbers. All of this spares the company from pre-producing large quantities of parts marked in a particular way. Inventory management is easier when you can serialize, apply logos and graphics or trademarking to a part on an as-needed basis after the fact.

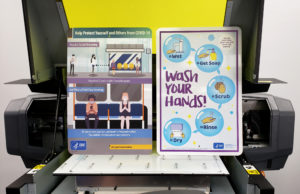

Opportunity or Seasonal Niches

Social distancing signage is a booming business. With regulations being added and changing regularly, retail stores and other companies need tons of signage:

- “We’re Open”

- “Curbside Pickup”

- “New Hours”

- “New Delivery Services”

And inside they need:

- 6′ separation floor signs

- Employee safety reminders

The CDC is even providing documents businesses can use for signage for a variety of situations. All of those can be turned into a UV printed sign onto corrugated plastic or even metal for parking lot signs.

If you haven’t been inspired to investigate UV printing for your business yet, check it out for yourself.

If you already have a customer base in almost any other customization niche, UV printing could help you grow your business more than you might think.