Photoresist film was created in the early 1980s by the founder of Rayzist Photomask, Ray Zukowski. Zukowski was using vinyl to etch wood signs, and the weeding was time-consuming. The designs were limited. He felt there had to be a film without weeding. He was a photographer and an entrepreneur, among other things, so with an idea and determination, he created a photoresist film. Rayzist Photomask was formed to seek out etching facilities that needed to maximize efficiency. At that time, etching facilities were using a tissue-style mask. A photoresist film would etch glass and crystal easily with depth.

Photoresist was being used at crystal companies all over the world, and it changed the etching process. Sandcarving detailed designs on glass became easier and faster. The photoresist film was produced thicker to become more sand resistant. The 6mil and 9mil were born. Detailed images, unlimited lettering, and emblems were now etched on

memorial stones.

After continued success using photoresist film on crystal and stone, we began to push the limits to other surfaces such as wood, art glass, bricks, metal, and even acrylic. In the late 1990s, Lazermask film was created to accommodate laser engravers wanting depth in glass and stone. It was simple: apply the Lazermask to the substrate, laser the image, and sandcarve. To make the process easier, a self-adhesive film was produced. Self-stick photoresist film was created for polished substrates in the early 2000s. With both films, you could etch any hard substrate.

Surfaces you can sandcarve

Today, sandcarving is one of the most versatile engraving methods. It allows for detailed etching across a wide range of substrates and irregular shapes. While glass and crystal are known for their stunning results when sandcarved, they are not the only materials that can be etched. Stone, metal, wood, and brick pavers are all surfaces that can be engraved by sandcarving. Photoresist offers an easy color-fill option.

Today, sandcarving is one of the most versatile engraving methods. It allows for detailed etching across a wide range of substrates and irregular shapes. While glass and crystal are known for their stunning results when sandcarved, they are not the only materials that can be etched. Stone, metal, wood, and brick pavers are all surfaces that can be engraved by sandcarving. Photoresist offers an easy color-fill option.

Although the basic sandcarving process remains consistent, the photoresist film and the application may differ. Depending on your substrate, select the best film for etching: nonadhesive, self-stick, or Lazermask film.

For crystal and glass, sandcarving provides exceptional engraving quality and can produce either a light frost or a deep etch, or a multistage carve. Because these materials have a smooth, polished surface, self-stick photoresist film is recommended. This film will adhere with pressure (squeegee), allowing for easier repositioning and eliminating the need to blast through a layer of adhesive, not to mention being easy to clean up. Design artwork for light frost or shading of glass to create a creative image.

Photoresist films vary in both thickness (mil) and adhesive strength. The film’s thickness should be selected based on the desired etch depth and the level of detail in the artwork. For example:

- 3mil is ideal for detailed artwork, thin lines, half-tone images, or small text.

- 4mil is designed for detailed images that require moderate depth.

- 5mil or higher is suited for bolder designs for depth and optional increased blasting pressure.

Glass

Self-stick films are best for polished surfaces such as glass and crystal, and for light surface etching on granite. The repositionable capability is ideal for alignment, realignment, and flexibility. For curved surfaces, remove the clear liner and then apply the photomask stencil.

Glass application steps:

- Clean the surface.

- Apply a self-stick photomask.

- With pressure, squeegee the mask and remove the clear liner.

- Roll a wire wheel brush over

the film to release trapped air. - Tape off exposed areas.

- Sandcarve to the desired depth.

- Optional color fill.

- Remove the mask and clean.

Stone

For natural, unpolished stone surfaces, use a photoresist film combined with brush-on or spray-on adhesive. Thicker mil films, such as 6mil or 9mil, are recommended for blasting hard substrates and higher pressure. On porous surfaces like concrete or bricks, add additional layers of adhesive for an aggressive bond. Add a color fill to create a contrast of the design.

Using a 6mil or 9mil photoresist film or a monument laser mask allows you to blast at higher pressure. Stone density varies; some etch very quickly while others are dense and take time to gain depth. In this case, increase the blasting pressure as you feel comfortable to etch faster.

Important tips for stone etching:

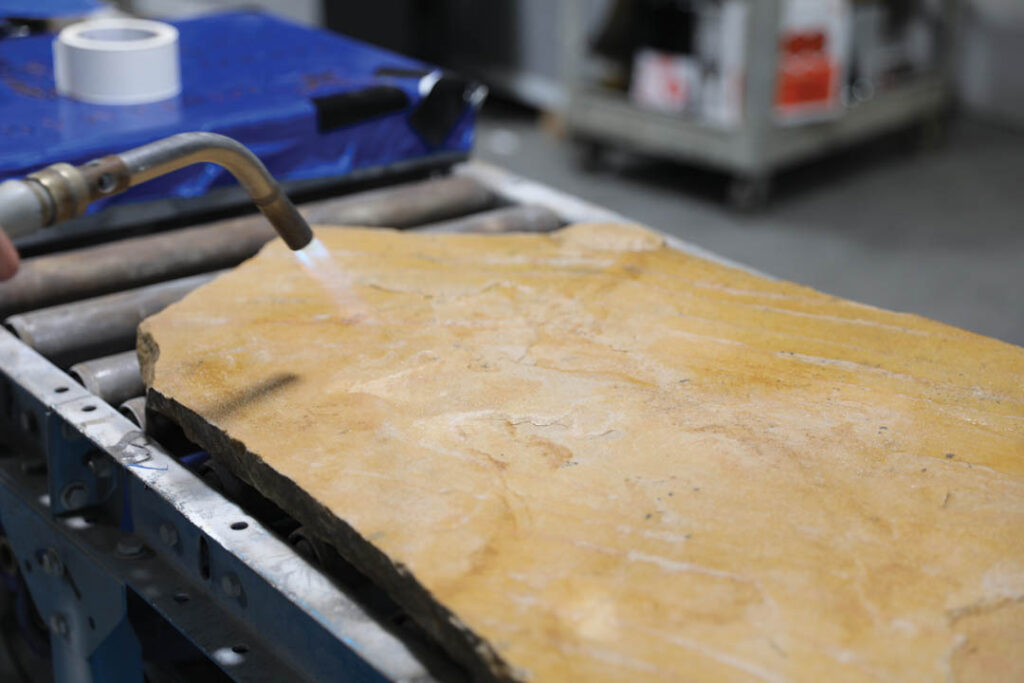

- Heat the stone with a mini torch or heat gun before applying the stencil. Natural stone contains moisture, and blasting will draw the moisture to the surface. Heating helps remove this moisture for a better bond. Applying heat is a must for etching stone. Heat until the stone is hot to the touch.

- Use a stone brush (nylon and brass bristles) to press the mask into dips or ridges. This prevents air from lifting the mask during blasting.

- Always blast at a 90-degree angle to maintain consistent pressure.

- The blasting pressure range is from 40 to 65psi for 6mil and 45-70psi

for 9mil.

Wood

Wood surfaces reveal beautiful grain patterns when sandcarved and are ideal for color fill. Use nonadhesive film with adhesive in 5mil for fine details or 6mil for bold designs. Sandcarving wood lends to either one color or multiple color fills for a creative appearance.

Wood application steps:

- Clean the surface.

- Apply nonadhesive photoresist film with adhesive.

- Squeegee and remove the clear liner.

- Sandcarve at 40 psi for 5mil or 40–50 psi for 6mil.

- Apply color fill for contrast.

- Once dry, remove the mask.

Metal

Metal can be sandcarved, but no depth can be achieved by only removing the polish or powder coating surface. Use nonadhesive film with adhesive to avoid residue left by self-stick films. Self-stick films will leave a residue on metal surfaces. For coated metal tumblers, use 5mil or 6mil film to allow for higher blasting pressure, helping to speed up etching. A double etch technique can also be used on coated metals to create a unique design. Decorate metal surfaces with one or more colors of paint.

Closing thoughts

Photoresist film is used all over the world to create beautiful designs. It is easy to etch a “Congratulations” for a new couple in a champagne bottle or a “Happy Birthday” in a wine glass, and even a pet memorial with photoresist film. Whether you are creative or keeping it simple, it can all be done with sandcarving and photoresist film. Happy engraving!