GRAPHICS PRO’s 2023 Market Intelligence Survey shows that only 9% of companies involved in laser engraving had lower profits than the previous year, and only 4% had a smaller staff than the previous year. This is encouraging news and falls in line with a recovering market after both Covid and supply chain interruptions.

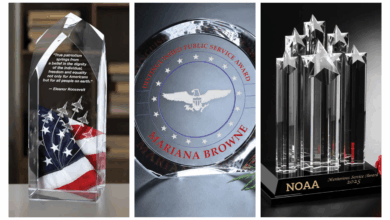

Awards and plaques are responsible for the greatest amount of revenue, and mugs and drinkware lead the field in terms of products sold.

Laser engraving continues to be a profitable market segment for graphics professionals and is a tremendous option for shop expansion. We asked a few industry experts about the laser engraving market and where the industry is heading.

Featured contributors:

David Stevens, Technical Development Manager, Trotec Laser

Tom Tamburrini, CEO/General Manager, Radian Laser Systems

Anthony Harris, Technical Sales Manager, Gravotech

James Stanaway, Director of Marketing, Epilog Laser

What are the top reasons a company should add laser engraving to its service offerings?

- “Laser machines can be used in a variety of different industries for all kinds of applications,” says David Stevens, Technical Development Manager, Trotec Laser. “Due to their high-speed accurate processing capabilities, lasers significantly increase production efficiency, allowing you to produce more finished products in less time. Lasers also offer a higher level of precision and better processing quality, which will increase the value and selling prices of your finished goods.”

- “Customer demand is already there, increased revenue and profits can be achieved if the jobs are priced properly, and recurring revenue stream if commercial customers are established,” says Tom Tamburrini, CEO/General Manager of Radian Laser Systems.

- “Customers add laser engraving to their service offering for many reasons; some customers are motivated by increased production rates, or the need to expand product offering,” says Anthony Harris, Gravotech’s Technical Sales Manager. “For others, the laser may be added to optimize other products or services. For example, processing leather patches, powder-coated tumblers, cutting printed transfer film or decals, or embroidered patches. The laser is often added to bring fabrication services in-house that are currently outsourced, like cutting dimensional lettering or acrylic parts/award blanks.”

- “Recognition is still very much important – whether it is trophies for a Little League team, a bridal party gift, or a corporate thank you token, personalizing products is a huge value add for existing and potential customers,” says James Stanaway, director of marketing, Epilog Laser. “Not only that, but larger corporate accounts – think hospitals and schools – who need signage, or device marking services can also greatly expand your product offering and profit potential.”

What are the biggest differences between a small hobbyist tabletop engraver and an industrial unit?

- Harris: Industrial lasers offer significant increases in productivity, engraving quality, consistency, and repeatability. It is common to see hobby lasers engraving at speeds of 20-30 inches per second to achieve acceptable quality, while industrial lasers can operate at speeds up to 160 inches per second while delivering highly detailed engravings. When used regularly, hobby lasers require constant tweaking and maintenance, replacing worn bearings, adjusting belt tensions, tightening of screws, optical realignment, and electrical connection repairs are common.

Image courtesy of AP Lazer. Another characteristic is power variance. If hobby lasers are used for extended periods, the chilled water reservoir needs to be replenished. When the reservoir water or environmental temperature changes, the laser output stability also changes. Industrial laser control systems monitor the source for heat buildup and adjust cooling fan speed, or industrial chiller to proactively control laser source temperature and keep power output stable. This ensures the marking result is consistent if you are marking 5 parts, or 5,000 parts in a day. It also protects the laser source and extends its life cycle.

The life cycle of hobby laser sources can range from a few hundred, to a few thousand hours. Industrial laser sources are expected to last 45,000 hours or more, on average. The drivers, firmware, and control systems in industrial lasers are significantly more stable and accept computer operating system updates. Industrial laser manufacturers also focus on laser safety to ensure the operator and workspace are protected. Active safety systems ensure the operator is protected from exposure to laser energy. If the door is opened while the laser is in operation, it immediately goes into a state of pause, until the door is closed and the start button is pressed to resume work. - Stanaway: Typically, the biggest difference here is speed and space, which primarily impacts production. Epilog’s most compact system, the Fusion Maker 12, features a 12″ x 24″ engraving table and engraving speeds up to 60 inches per second, whereas our Fusion Pro laser series features machines up to 48″ x 36″ engraving tables and 165 inches per second engraving speeds. Obviously, the larger the table and the faster the machine, the more products you can produce.

We often see customers coming into the industry electing a smaller or mid-size machine and more often than not, we’ll see them upgrade to a larger, if not high-powered system in the next 1-3 years.

Another difference that is worth noting is the type of laser tube that’s used in a particular model. All of Epilog’s lasers are air-cooled metal and ceramic tubes. Glass tubes are more fragile and tend to have a shorter lifespan. While they can adequately cut materials, they don’t produce the incredibly precise engraving results you can see from metal/ceramic tubes. Lastly, glass tubes require a water chiller to regulate their temperature, which adds an extra cost to your operations and adds space to the footprint for your equipment setup. - Tamburrini: Performance and reliability are the main advantages.

- Stevens: Small hobbyist lasers are great for anyone looking to get their feet wet in the laser world, while industrial lasers are geared more toward production-focused environments. Industrial lasers will likely have larger bed sizes, higher wattages, and specialized accessories. Industrial lasers will likely have faster processing speeds and better-quality components (motors, laser tubes, etc.) The proper machine widely depends on the application itself, volume, and budget of the laser user.

How long does it take a first-time user to become proficient with their laser engraver to the point they can feel comfortable taking orders, and how much education is involved?

- Stanaway: This depends on a lot of factors. The laser system itself is fairly intuitive and easy to use. More often than not, users take longer to become proficient with running their graphic design software than the actual equipment itself.

We encourage our users to get a good base knowledge of the software they’re using, such as CorelDRAW, and practice, practice, practice. The same goes for different substrates. Go to the thrift store or online selling forums for cheap materials and learn how the laser reacts with those substrates. The discount dollar-type stores are also a great place to get practice items, especially glass.

Your commitment to getting up and running and taking orders is directly proportional to how much effort you put into learning how to design for and run your laser. You will learn a lot at the beginning, and the more you experiment, practice, and design, you will continue learning through your lifelong journey as an engraver. - Harris: The amount of time it takes to achieve laser proficiency can vary for new users, it depends on the application being addressed and the user’s transferable skills. If the operator is already familiar with rotary engraving, vinyl cutting, sublimation, embroidery, or digital printing, they become proficient much faster. Industrial laser manufacturers incorporate material profile databases and material calibration wizards into the software to assist users in getting off to a fast start. Design Software packages such as Laserstyle include embedded videos and linked instructions to assist with software proficiency. It is always recommended that a new user invest in training. The confidence gained in a session of 4 to 6 hours allows the operator to advance with a good foundation of knowledge and makes them aware of available resources.

- Tamburrini: It really depends on the user and what other type of experience they have that can help or hinder their learning curve on the machine and also their business acumen.

- Stevens: Familiarity with advanced technologies like laser systems is an ongoing process. Lasers are regularly being updated and improved, and the variety of possible applications is almost endless. Some laser systems and laser software platforms are designed to be user-friendly, and training can be completed in as little as a day. When looking to purchase a laser, it is wise to consider manufacturers who offer additional training in the form of webinars, seminars, educational events, and tutorial videos. These additional resources can be very helpful for beginners looking to become more knowledgeable.

What skills help the most when running a laser engraver? Do you need to be a graphic designer?

-

Image courtesy of Kern. Tamburrini: Mechanical aptitude is a must. basic computer skills are required to operate the software and to load files. You do not need to be a graphic designer to run engraving machines, but you will need to find someone to work with that can generate artwork.

- Stevens: Proficiently running a laser engraver does not require the background of a graphic designer, although it doesn’t hurt. Many standard graphic software programs are user-friendly. Some lasers even offer graphic editing directly within their software, further simplifying the learning curve. More recently, AI-generated content has become a popular topic across a wide variety of industries, and the graphic arts community is no exception. There are various AI programs and platforms out there that can assist laser users with the quick and easy creation of files.

- Harris: It is not necessary to be a graphic designer or have exceptional computer skills to operate a laser. Basic typing skills and a good eye for layout symmetry help. If the user has experience adjusting contrast and cropping photos, they seem to ramp up faster. Laser design software packages like Laserstyle include import filters and tools that make importing logos and graphics easy. The PhotoLase module allows you to select a picture and choose the material it will be lasered onto. The program adjusts dithering, contrast, image polarity, and DPI for the chosen substrate. Included tools like PhotoLase, variable text importation, multicopy layout, columns layout, print and cut registration, and material calibration wizards, significantly reducing the path to proficiency.

- Stanaway: You don’t need to be a graphic designer, but you do need to be at least proficient in the design software of your choice. Most of Epilog’s customers use CorelDRAW or Adobe Illustrator.

We recommend learning – at least – the basics: cleaning up logos, removing backgrounds on graphics, text effects, etc. Epilog offers a variety of beginner-type projects in our training suite, as well as our Sample Club, which is updated regularly with files people can download and experiment with. We also provide starting points on the speed and power settings of the laser. YouTube is a great resource as well where laser operators can find a wealth of information and design tips and tricks.

How much space is required to set up a laser engraver, and what are the power requirements?

- Tamburrini: Each machine is different and has different footprints. You may also need to consider space for a chiller for water-cooled machines. Some machines operate off of 120VAC and some require 220VAC.

- Stanaway: This depends on how much equipment you can comfortably fit in your space. Our smallest machine dimensions are 39.5″ W x 26.5″ D x 17.9″ H and our largest is 41.52″ W x 32.81″ D x 40.54″ H, and we have a couple of other options in between.It’s important to keep in mind that to run the laser properly you’ll need some sort of exhaust system and/or way to vent the laser. Most people opt to vent outside, but if that’s not possible there are portable filtration systems you can use. Those vary in size as well, but the size we generally use for tradeshows and expos is approximately 30″ H x 18″ W x 20″ D. Depending on how many tools you have in your arsenal, overall you’ll need space for the laser, desk/computer set up, and ventilation system should you need that.

Most of our systems run on standard 110-volt electricity; however, our largest machine, the Fusion Pro 48, requires 240 volts. - Harris: CO2 lasers with 12″ x 18″ or 12″ x 24″ work areas are very compact when paired with a filtered exhaust base, they require about the same footprint as a household washing machine. A household power supply of 120 volts on a 15-20-amp breaker is fine for most air-cooled industrial lasers under 80 watts.

- Stevens: Laser engravers can range from desktop units to large-format bed sizes, so the space required will vary depending on the type of laser and the bed size itself. It is important to discuss various requirements such as electrical exhaust with your laser sales professional as different systems have different requirements.

What is the most significant technological advancement in the laser engraving field in the past few years, and how has it helped customers improve their business?

- Stevens: Recently, there have been significant developments in the areas of software and hardware, and we will without question see further improvements in the coming years. New features like integrated cameras have made positioning artwork onto workpieces easier than ever. Also, new updates allow for graphics editing to be done directly within laser software. This direction could offer major possibilities for improving workflow and streamlining the production process from idea to end product. These are the kinds of advancements that will make equipment easier to use, improve production efficiency, and reduce costs.

- Tamburrini: There are many advances in the field. Software is improved, laser components, optics, and electronics are all improved, perform better, and are more reliable than ever. Cost is also lower for entry-level machines. The barrier to entry has dropped compared to years past and that has helped companies get started faster.

- Harris: Combined advancements in laserable materials, design software, and laser technology are evolving the market and reducing the learning curve for new users. New laser-compatible substrates for leather patches, heat transfers, transfer film for decals and graphics, new laminated plastics, environmentally friendly toxin-free wood for laser processing, metal marking compounds with improved adhesion, and more forgiving power settings are opening new markets of opportunity.

Graphic programs designed for laser and engraving applications reduce the learning curve and help ensure success. Hardware and software advances make functions like point-and-shoot plate layout, point-and-shoot text location, and point-and-shoot text on a curve, circle, or shape, possible.

Now you can use the red pointer to define where multiple text fields will be positioned and sized when laying out a complex serial rating plate or define a shape or object (heart-shaped box, watch back, etc.), and typed text will follow the indicated contour. Newer technologies including galvo laser platforms have become more economical and user friendly. Galvo lasers offer processing speeds that are 5+ times faster than gantry lasers.

The compact Welase series is offered in different laser energies (wavelengths) allowing you to choose between C02, Fiber, Hybrid (YVO4), and Green Laser Sources. Having source options enables you to achieve vivid and permanent contrast on single-color plastics without removing or damaging the surface, achieve black marks in stainless steel, brass, gold and silver, and other metals, without the need for marking compounds, or cut metals for jewelry, medallion or stamping die fabrication. - Stanaway: By leaps and bounds, the most significant technological advancement in laser technology over the past few years has been the development and implementation of camera technology that helps take the guesswork out of where graphics/text will engrave on a product. Epilog has been at the forefront of this technology as we introduced Epilog’s IRIS Camera System, which allows users to position artwork and graphics quickly and accurately by providing a real-time image of the engraving bed.

When we first introduced the IRIS Camera System on the Fusion Pro Laser Series, it was a game changer. This valuable tool – now available on all the systems in our current product lineup – helps operators get up and running faster than ever before, and when they know exactly where their graphics or images will engrave, it saves our customers time and greatly reduces material waste.