If you’ve been around the garment decoration industry for any length of time, then you know that every few years there’s a new decoration technique that captures everyone’s attention and is proclaimed the next big thing. Way back in the day, it was sublimation that had everyone scrambling to figure out how it worked and how it could be used to make a profit.

After that, direct-to-garment (DTG) printing was proclaimed the next big thing, and manufacturers worked to dial in printers and ink while decorators struggled with a learning curve that could sometimes be a bit steep. In today’s industry, the newest technique is direct-to-film (DTF) printing. It’s being touted as the next big thing and manufacturers, and shops, are working to wrap their heads around how it works and what potential it holds.

What is DTF?

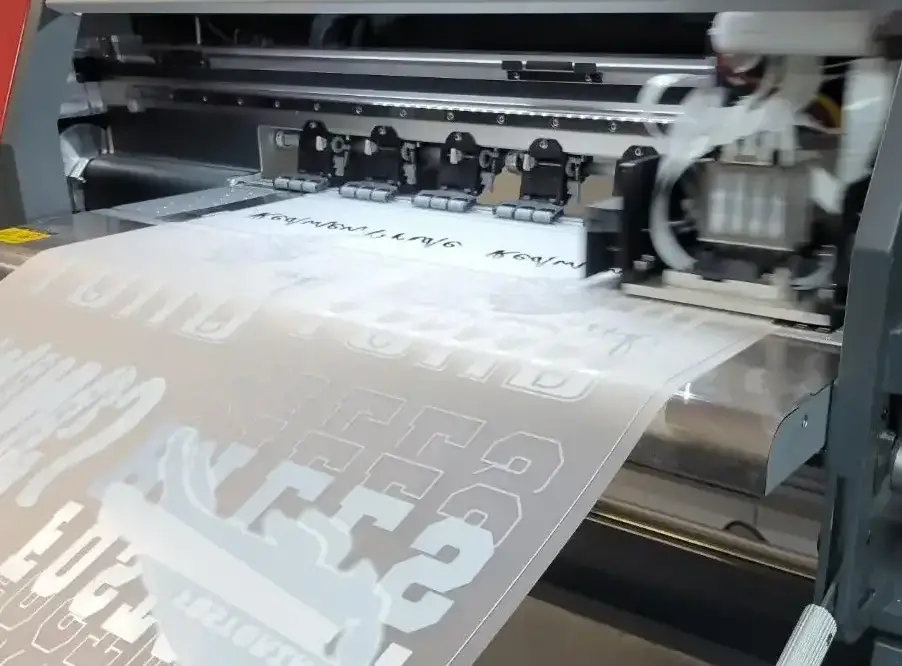

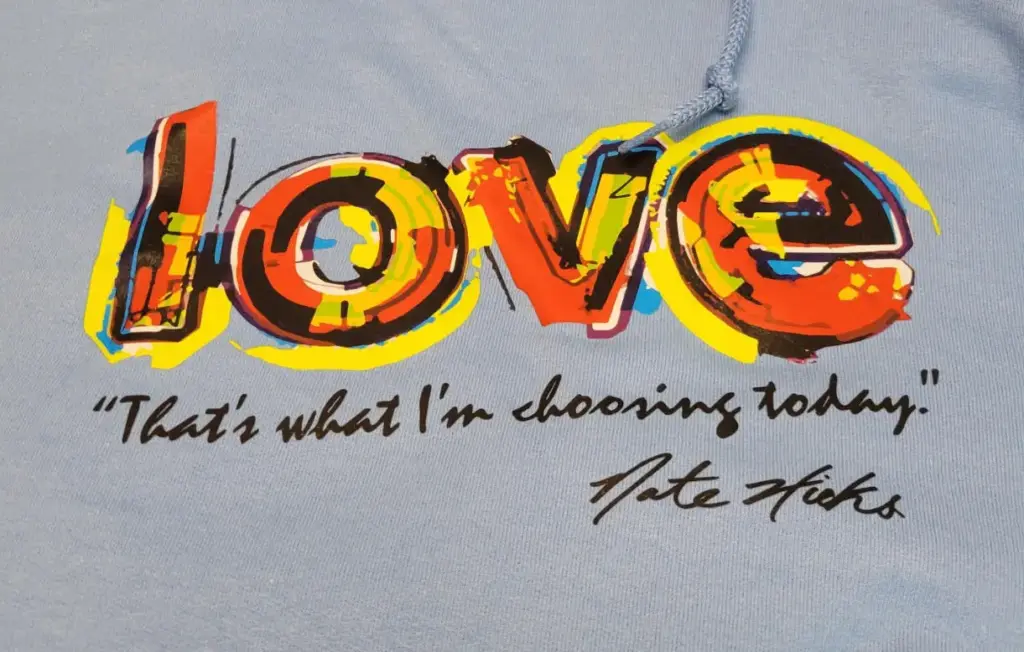

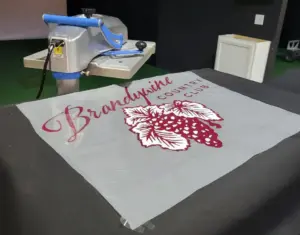

For those who aren’t familiar with DTF printing, the process consists of printing color graphics onto film using a specialized printer and inks. The graphic is then transferred to the garment using a heat press. DTF prints can be printed using white ink, which means the prints can be used on dark colors. The graphics are printed using a special printer and textile inks onto a specific film. The design is then coated with a powder which acts as an adhesive, allowing the design to adhere to the garment when it is pressed. DTF prints can be used on cotton, polyester, or blended garments, meaning that decorators are offered a wide range of options, in both color and materials, when using this method to decorate.

If you are interested in DTF printing, there are basic things you will need to do to get started. The first thing is to figure out if there is enough interest in DTF printing in your target market to make it profitable for you. There are ways to go about finding out this information. Some shops might start out buying DTF transfers and offering the option to their customers that way. Once enough business has built up, the shop will then move on to having in-house equipment. Other shops might survey their existing customer base or float the idea on social media and see what sort of response comes back. Setting up to print DTF graphics will entail some effort and some cost, so it’s wise to be sure a market exists before investing your time and money.

The other thing to do before investing in any DTF equipment is research. DTF printing has specific requirements and stipulations and it’s wise to know what you’re getting into before you waste your effort and your funds. BK Custom T’s Owner Becky Kotzer says she “read as much as possible in forums and connected with several industry experts as I was getting into DTF and converting.” Lisa Lemonick of Scrappy Dappy Doo spent months doing research before pulling the trigger on purchasing a DTF printer. Amy Carpenter of Frog Town Tees watched “many, many hours of videos” and had “in-person questions for company reps” before making her decision about buying a printer.

Once you’re sure that at least the beginnings of a market for DTF prints exists among your target customers, and you have some ideas about how the equipment works and what you can do with it, it’s time to make a decision about what to purchase. There are several ways to do this. One option, used by Lemonick, in Manalapan, New Jersey, was a combo platter. As she puts it, “We researched online first, then we went to the ISS Show in Atlantic City and saw the machines in person.”

Lemonick elected to purchase online after being able to see and handle the equipment at the show. Carpenter, in Maumee, Ohio, also did her research at a trade show and elected to buy equipment at that show. She found her equipment at GRAPHICS PRO EXPO in 2022, explaining, “We bought from Axiom America.” You can also, as Kotzer of Groton, South Dakota did, convert a printer yourself. Becky states, “I started with desktop printers I converted myself. I then moved to a commercial printer.”

The cost of doing business

The cost of setting up to sell DTF transfers or garments with DTF prints can vary. Printers alone can range from $2,500 to $20,000. Heat presses also have varying costs, and both the cost of the printer and the heat press will depend somewhat on the size you elect to purchase. You will need both printer and heat press, as well as film on which to print, and DTF powder to serve as an adhesive. You may also want a cutter or a plotter to be able to cut designs prior to placing them on garments.

Another option may be a DTF curing oven, although a heat press can offer the same functionality. Some shops will elect to use a heat press for both curing and pressing. Other shops may choose to use an oven to cure the prints. Part of the decision about what equipment to buy may be dictated by what you’re planning to sell. If you’re planning to decorate garments, a heat press will be necessary. If you’re thinking that you’d just prefer to sell printed transfers to others, you may be able to manage with just a DTF curing oven. There are shops that make a sizable profit just selling printed transfers and not doing any decoration themselves, so that option is a viable one.

If you’ve done your research regarding DTF, you may have heard or read stories from people for whom DTF was problematic or didn’t work out. For Lemonick, the scariest part was “hearing all the problems people had, but with the proper training from our supplier, we are more comfortable doing it.” The hardest thing for Carpenter was “finding the correct machine and getting it running well.”

Expect to have a learning curve with DTF, as you would with any new discipline. Be aware that you will have to invest time and effort to learn to print well and that you’ll probably have some misprints along the way. There is a cost, both in money and time, when learning to do something new, but those who are already running DTF businesses will tell you it’s worth doing.

What can you offer?

As with any decoration discipline, DTF printing offers a variety of options for products that a shop can sell. Kotzer says, “I can say yes to one and two item orders and have full color and texture in my designs.” For Carpenter, the advantage of offering DTF prints is “versatility, the ability to do custom prints or only a few items for customers.” She also likes “the ease of printing transfers for other businesses.” Lemonick finds it useful that “we literally can do all kinds of detailed work that we couldn’t do before unless it was sublimation on a white T-shirt.”

One of the advantages of DTF printing is that you can print transfers to decorate items for customers, or you can simply sell the transfers by themselves. Customers of Scrappy Dappy Doo can get graphics for T-shirts, but the shop has also tried DTF prints on acrylics and hoodies and is looking at trying out decorating sneakers.

Frog Town Tees offers garments, tote bags, items in combination with lasercut decorations, and a ton of transfers. BK Custom T’s sells a lot of transfers as well as decorated apparel items. Since many people may start out using transfers before investing in equipment of their own, selling just the printed transfers may be a profitable angle for some shops.

If you are thinking of starting your own DTF business, be aware that there is a learning curve, and you’ll have to put some time and effort into making the business work. As Kotzer comments, “DTF is not for the faint of heart. It is not a matter of if the printers will have mechanical issues, it’s a matter of when. Learning to fix minor issues is key to your success.”

Lemonick advises that printing DTF takes time, but making the effort is worth the time it takes. In her words, “It is time-consuming to prepare the film with the powder, but the end results are so worth it.” For Carpenter, the thing to remember is that you get out of DTF printing what you put into it. She says, “It’s a great addition to other mediums and is really profitable if you are willing to put in the effort to get the correct equipment and keep it running well.”