Small-Format Printing: Shops Playing Small Ball

Getting a leg up on the competition with small-format specialty printing

In 1910, the dead-ball era in baseball was forever changed by legendary New York Giants manager John McGraw who popularized the strategy of “small ball” which featured the stolen base, bunting and moving runners over to score runs. In fact, the 1911 New York Giants stole an incredible 347 bases; a record that still stands today. These moves physically changed the way the overall game was played, requiring upgraded equipment, new rules and a new style of managing. More than a hundred years later, thinking small is also helping to change the rules in the wide-format market as well, with shops that may be considering adding small-format printing to their list of services.

As the digital sign industry grows and evolves, more customers are requesting customized products such as on-demand labels, T-shirts and personalized promotional items. Initially to meet this demand, sign shops began using their wide-format inkjet printers for these applications but found it in some cases to be a slow, costly and cumbersome process. In addition, these smaller jobs also tied up wide-format equipment when these machines could be better served pushing out much bigger projects.

As a solution, many shops have begun investing in toner-based and UV-curing small-format printers to offer numerous new applications to fill these smaller niche opportunities.

“More and more we are seeing a big trend towards more full service graphics outlets rather than application specific shops. What does this mean? Businesses used to identify themselves as sign shops, screen printers, embroiderers and trophy shops,” says Don Copeland, product manager-Direct to Garment (DTG) Printers and Compress UV Printers at ColDesi, Inc., Tampa, Florida.

“Now we see businesses offering multiple output options for the graphics they create, or are provided by their customers. The advent of more and more digital output solutions at more affordable prices has made it more about the graphic and less about specialty application techniques,” Copeland adds.

Shops Going Small

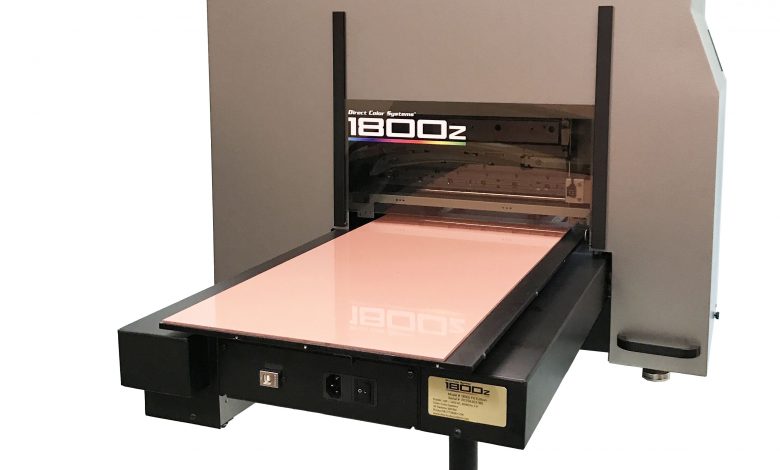

Michael Perrelli, marketing manager at Direct Color Systems (DCS), Rocky Hill, Connecticut, reports that sign shops represent one of the biggest markets for small-format UV LED printers and they are using the equipment in a myriad of ways. “For example, shops are doing away with the laborious appliqué and bead method for ADA/Braille sign production and replacing it with a digital UV LED print process that allows the operator to work on other items while the printer does its work. Others use it to digitally print full color background graphics and colors instead of paint or vinyl stickers.”

Perrelli points out that there are a few trends in UV printing worth noting and they are all happening simultaneously. “The switch from analog to digital continues to grow each and every year. Companies (both big and small) are looking to replace labor intensive processes, increase profit margins by offering customization with low (or zero) minimum quantities with zero set ups, move to full color capabilities as well as leverage the versatility of the printer to build upon a current market share or be ready to enter new ones when the opportunity arises.”

He says shops are also looking for versatility. “Whether it is a trophy shop looking to get into digitally printing ADA/Braille signage, a sign shop looking to enter the DTG market, or promotional product e-commerce sites that don’t want to farm out custom bottle production-UV printers are a versatile equipment option for the current book of business and the business the company hopes to attain in the future.”

Lastly, he says, applications continue to grow. “When small-format UV LED flatbed printers started, most of the capabilities centered around opaque white ink, vibrant colors, and high quality flat prints. Now they can produce remarkable TEXTUR3D prints (that can be seen and felt) in both color and clear ink, ADA/Braille signage (patented by DCS), cylindrical and conical products, flexible items like wallets, and custom T-shirts. It’s an exciting industry to be a part of going forward.”

He adds that sign shops are also using these printers to upsell current customers. “Now they can offer their corporate, municipal, or educational sign accounts the option of also doing their awards, practice jerseys, or promotional items. Digital, full color capability with the ability to print to many materials allows shop owners to let their creative team go wild, step out of the box, and wow customers…all with enhanced profit margins.”

Benchtop UV Flatbeds Gaining

Jay Roberts, product manager, UV Printers, Roland DGA, Irvine, California, says one of the biggest trends in small-format digital printing, and digital printing in general, is the growing demand for benchtop UV flatbed printers, such as those offered within Roland’s VersaUV LEF series. “These innovative inkjets make it quick and easy to customize and personalize just about any type of substrate or three-dimensional object with vibrant, detailed graphics. Being able to transform standard or blank products by adding unique printed designs and eye-catching dimensional effects allows for the creation of products with a higher perceived value than typical mass-produced offerings.”

He said their 12-inch LEF-12i and 20-inch LEF-200 UV flatbeds, which fall into the “small-format” category, are allowing our customers to cost-effectively produce a vast array of customized items, dramatically increasing sales for our customers. Roland also offers a 30-inch LEF-300 model, which offers maximum versatility and productivity.

“This customization/personalization trend is affecting all types of markets and buyers. Having the ability to customize everything from picture frames, shoes and cell phone covers to water bottles, hats, cases and luggage has opened a new world of opportunities. It all stems from the buyer’s natural desire to “create” objects that reflect his or her own individual look and style,” he points out.

Roberts adds what really makes UV printers different is that they’re capable of creating products that are ready for shipment as soon as the printer is stopped. “Recently, I watched one of our customers literally pick up an item he customized on an LEF-200 printer, insert it into the mailing box, and ship it out. Other than inserting an invoice or purchase order, it was ready to go.”

Upgrades in Heat Transfer Technology

Matt Davies, national sales director, New Business Development, OKI Data Americas, Irving, Texas, reports that there also has been significant technological improvement made in the heat transfer technology market segment. “As a result, we are seeing exponential growth in this market, as sign shops and other similar companies begin to realize the breathe of products that can be decorated utilizing a single base technology. They are beginning to see that there are new revenue opportunities within their existing base. They also get to utilize much of their current graphic arts capabilities.”

Davies points out that when it comes to small format, he considers two of OKI Data’s technologies, which could be applied. “The first being our 942 printing system, which has the ability to print over-sized tabloid printing with a single pass white toner technology (printing white first). This allows a beautiful color on color printing technology at speeds up to 50 ppm. The other unique capability is that this is a straight path printer, which allows a wide range of substrates for both paper and polyesters, as well as other unique substrates with a wide range of colored stocks.”

He says the ability to print single pass white toner production is becoming more successful every day. Other manufacturers such as Xerox and Ricoh are seeing the same trends based on their product introductions over the past two years. “We are seeing a constant growth in this market segment, which we believe would also be useful in the sign market as well.”

He adds that the other technology, which the company has been excelling at within the industry, is their printers designed specifically to print using heat transfer technologies, also using their single pass white technology, but now printing white last (instead of first), to allow a color on color heat transfer to other substrates. “In this technology, white needs to be printed last since it will be first color when transferred to a substrate.”

One Stop Shop

Davies reports that with a minimal invest of just under $10,000 (printer, heat press, transfer papers and other minor items), with little to no disruption to their business work flow or creating new space issues, sign shops can now have the ability to create for a customer small format items, which their customers may have previously gone to a different provider to have created. “They can now add more ‘one stop shop’ ability to their existing customer base. They have the ability to produce small signs, mugs, plaques, tote bags, decorated glass items and T-shirts for more expanded advertising material to their customers.”

He adds that his technology has a small footprint and minimal investment but has big returns in shorter time periods. “Wide format clearly has its place in the sign market for large and powerful messaging. The small format gives shops easy, convenient, quick and versatile marketing capabilities, which could never come from a wide-format platform.”

“For example, a semi truck can deliver a great many products at one time over long periods of time, but a local delivery truck can deliver quickly and precisely what a customer needs for smaller and more immediate opportunities. Just like the delivery service scenario, small-format and wide-format can work hand in hand to meet the many changes that the market demands quickly and efficiently. This type of understanding will help the sign shops in the future to offer more services to their customers, thus giving them a more unique business service offering,” Davies concludes.

Moving into UV Printing

Copeland says he sees more traditional sign shops expanding into UV printing to reduce labor and material costs for output on signage such as Coroplast, aluminum and even wood. “They are also looking to expand their reach into promotional items as well, such as with the very popular tumbler business from Yeti, RTIC, Ozark Mountain, etc. Secondly, they are often looking for a quick solution for doing short-run T-shirts for their customers. Both DTG and full color lasers with white toner, like the Digital HeatFX, are becoming popular for graphics shops not already doing apparel to expand their reach.”

Copeland reports the most common application is 18″ x 24″ Coroplast signs as well as more permanent signage printed on aluminum and steel sign blanks.

“UV printing opens up printing direct onto pre-assembled items. The range of items here is staggering. We have printed on wooden wine cases, sports equipment, prototype packaging, toys, baseballs, golf balls, control panels, picture frames, vehicle magnetics-the list goes on and on,” he reports.

Big Benefits

Perrelli at DCS reports that Z-height is an obvious benefit for the small-format printers. “Fully adjustable options up to 15-inches are unrivaled by many wide formats. Couple that with the ability to jump back and forth between jobs and products (such as signs to bottles and then to phone cases) quickly and easily, are some of things that the wide formats can’t match.”

He continued, “Some of our largest customers will use numerous small-format printers instead of one or two large formats for certain divisions because of the versatility and redundancy that the small formats provide in a production world. A single person shop or a small team can operate many small-format printers at the same time,” he concludes.