Signage: The Unforeseen Printing Trend of 2020 and 2021

The role signage played in local communities and the technology behind it

Over the past year, new and unforeseen circumstances have impacted the economy and print industry. Sign shops of all sizes have had to re-evaluate business plans to keep doors open and meet new, ever-changing state and local regulations. As an industry, printing has pivoted.

Many local print shops maintained an essential business status by leveraging their technology to create personal protective equipment (PPE), while others used their equipment to create a variety of signage to support local communities. As a result, printing orders have increased for both corporate and residential signage, and print shops have proven to be an essential part of the new and changing city infrastructure.

As state and local regulations changed, it was crucial for sign shops to help local businesses with marketing and communications strategies to ensure local employee and customer safety with the most up-to-date information. Print shops were the backbone of relaying local messaging. Signage and its corresponding printing technology became imperative to keeping customers informed and local businesses top of mind.

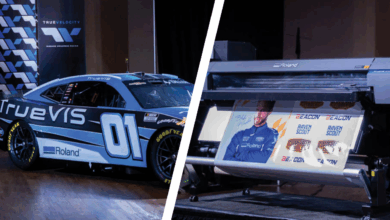

Signage was everywhere, from branded to-go packaging items, “We’re Open” banners, and in-storage signage and floor spacing for local shops, to supporting local communities with yard signage for virtual graduations, birthday celebrations, and political communications. To complement the growing signage orders, manufacturers received a spike in incoming orders as print shops looked to increase efficiency and expand signage product offerings.

Outdoor signage and solvent technology

Outdoor signage has become so common that it is often part of the scenery, unconsciously absorbed, and rarely discussed. However, this year outdoor signage became a primary way of communicating.

In addition to traditional billboards and building wraps, local sign shops have seen an increase in banners being printed for brick-and-mortar stores and local restaurants, yard and street signage to represent local and national political candidates and propositions, and even neighborhood signs in lieu of traditional gatherings to celebrate graduations, birthdays, and baby showers. Signage has been a primary way of making people and local businesses feel seen, heard, and celebrated during this difficult year.

When creating outdoor signage, sign shops know that ink technology is critical. Solvent printing has become synonymous with outdoor signage due to its ability to withstand a variety of weather conditions and retaining a professional and clean look without smudging. Solvent output is considered weather-resistant, durable, smudge-resistant, scratch-resistant, and impervious to hazards such as abrasions and cleaners. For sign shops looking to invest in a new solvent printer, the three factors to look for include color gamut, lamination time, and efficiency.

A wide color gamut is critical for printing signage. It’s important to capture custom brand colors and have the ability to achieve any color thrown into the project. Today, select solvent printers have the ability to hit over 98% of the Pantone Color Guide by offering ink colors outside of the traditional CMYK color scheme. Advanced solvent printers offer formulations in red, white, and metallic silver to support the expanded color gamut and hit specific branding colors such as Coca-Cola red or Barbie pink.

In addition, when selecting a solvent-based printer, sign shops need to consider the off-gassing time. All solvent prints are required to go through an off-gassing process that can take from 24 to 48 hours.

During busy seasons with orders waiting to be fulfilled, it is important to find technology that is efficient and works with a print shop’s existing workflow. Due to rapidly changing technology, there are now solvent-based signage printers that reduce the off-gassing period to the same day, or as fast as six hours. Leveraging a signage printer with a lower curing time, local print shops can quickly laminate and complete the influx of projects with less downtime, allowing for additional jobs and increased revenue during the year.

Indoor signage and resin technology

While foot traffic declined for large retailers this year, many consumers have stepped up to support local brick-and-mortar shops and restaurants. Communities have come together to show appreciation for their local businesses.

Retail stores, restaurants, bakeries, hair salons, and just about every type of business with walk-in customers required additional signage this year. Whether it was posting updated health and safety guidelines, incorporating new floor graphics that identify the required six-foot social distancing, or updating store-specific guidelines to protect workers, local sign shops fulfilled these changing needs. With ongoing changes from the government, these signs had to be replaced often, underscoring the relationships between local businesses and sign shops fulfilling the orders.

Because there is a wide variety of indoor signage, print shops should invest in technology that specializes in output versatility. Indoor signage encompasses everything from wall-mounted advertisements, wall and floor adhesives, and hanging restaurant menus, to wayward signage and more. Customers are generally closer to this output and therefore color consistency, quality, and output durability are essential.

Similar to outdoor signage, there are different attributes to look for when printing indoor signage. Multipurpose resin ink does not require an off-gassing process, delivering environmentally cautious, professional-quality graphics that are highly scratch-resistant for a variety of media substrates, making it an ideal technology for indoor signage. The variety of substrates allows print shops to provide customers with options ranging from wallpapers, fabrics, uncoated papers, and other traditional signage media.

Another key benefit of resin printing technology is its ability to deliver consistent, repeatable color. This is great for indoor signage where customers may be close enough to see the different printed panels. Consistent, repeatable color delivers output ideal for hitting specific brand colors, large wall installations, and repeat orders placed months later.

In addition, short-term indoor graphics produced with resin inks often do not require lamination due to their high scratch resistance. There are now resin printers in the market designed for fast-paced environments that incorporate integrated heating technology and deliver output ready for immediate lamination and hot-swappable ink systems, automatically switching from an empty ink pack to a new ink pack mid-print for uninterrupted printing.

Nontraditional signage and UV flatbed technology

In a year where signage has been crucial for communications, non-traditional signage has also been popular. This includes promotional goods, rigid substrate prints, branded takeaway items, and more. Every local restaurant struggling with new guidelines has had to adapt and remind customers they are open for takeout or outdoor dining.

A great way to stay top of mind is by providing branded takeaway items to customers. These items then serve as signage to others who see them, serving as a visual reminder that the business is open. Custom printed wine glasses and mason jars also serve as unique takeaway items in states where restaurants served to-go alcohol for the first time. This year the political atmosphere also leveraged nontraditional signage by using branded pop sockets, coffee mugs, phone cases, bumper stickers, and signage board yard signs.

There is an endless number of nontraditional signage opportunities that require a flatbed printer in lieu of traditional roll-to-roll printers. One of the key benefits of flatbed printing is its versatility — flatbed printers can handle traditional media as well as thick signboards and promotional 3D items without requiring additional lamination. The ability to print on thicker media is ideal; it provides enough space to print on a variety of thick wooden or PVC board signage, perfect for tables, doors, and other 3D items.

Today, there are UV flatbed printers on the market that accommodate thick media and deliver outstanding ink technology, touting up to 10-color ink sets featuring red ink, gray, opaque white ink, and varnish for added effects. If your UV flatbed printer includes white ink, make sure there is a circulation system to limit sedimentation.

Key takeaways

Nobody could have predicted the significant role the signage industry would play in 2020, and even in these initial months of 2021. Manufacturers received an unforeseen number of orders on signage printers to accommodate the changing climate. As the industry continues to adapt and print shops purchase new equipment, it is critical to understand the benefits of different ink technology, as well as limits and potential versatility.

However, the applications over the past year underscore signage printing advancements and the importance of ink versatility as print shops cater to meet changing customer output requirements.