Signage and Heat: Why It’s Important to Plan Ahead

Depending where you are, climate can play a major role when it comes to designing and installing electronic signage

Have you seen the new hot sign designer they just hired in the design department? Unbelievable-and I heard that “being a hot sign designer” was all they cared about—does HR know about this?

Let’s face it, if you’ve worked in a sign shop with a sign designer in the office, you have to admit that the eye candy that a “hot” sign designer can bring really should be of little concern to HR. It’s something that every sign design department needs and should have, for the overall good of the entire company.

Being a sign designer is one thing, but being a “hot sign designer” takes years of practice with hands-on experience in understanding what it means to be a hot sign designer. Naturally, we are talking about sign designers who have experience with sign design in hot climates. Places where signage is produced for applications in areas of the country where summertime outdoor temperatures exceed that of most countertop toaster ovens. This type of heat can have negative effects on the materials used to create the sign, hence steps must be taken to avoid problems when the mercury soars.

Heat affects vinyl, acrylic, polycarbonate, steel, aluminum, paint, powder coating—basically everything.

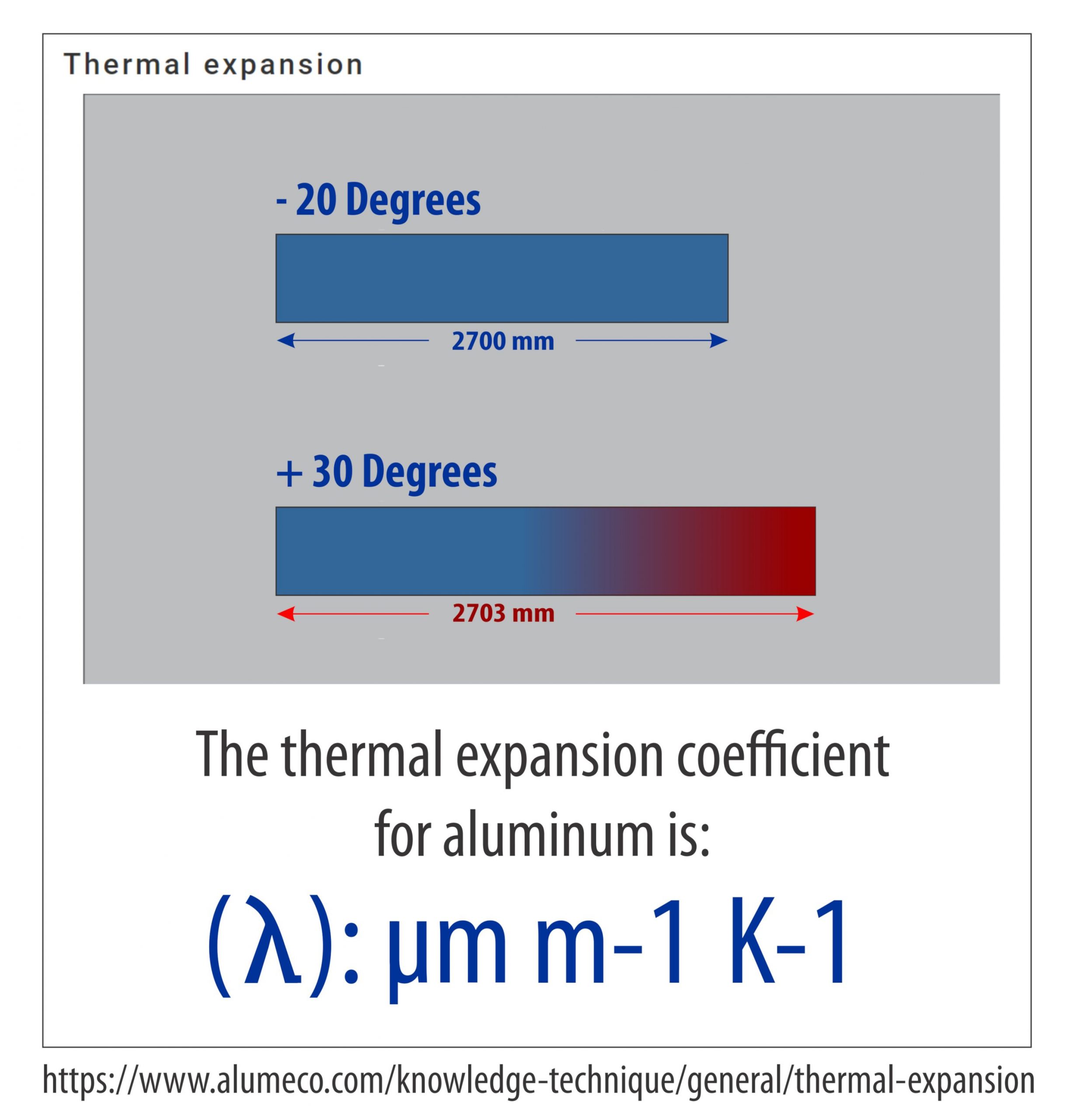

When materials get hot, they expand and when they do, it is referred to quite simply as thermal expansion. Unfortunately, not everything expands at the same rate, or in the same way. When building an electric sign, the combination of aluminum and acrylic can be a recipe for disaster if the temps get up there and expansion issues have not been planned for.

Expansion coefficient

There is a technical term used for thermal expansion that sounds a lot more impressive—expansion coefficient. It’s the scientific formula that provides data on the way in which a material expands or contracts in all directions with temperature fluctuations.

So how do you know how much each material will expand? The rule of thumb is to leave plenty of room, and don’t tighten down two different materials without including oversized holes to allow for expansion.

Calculating expansion rates

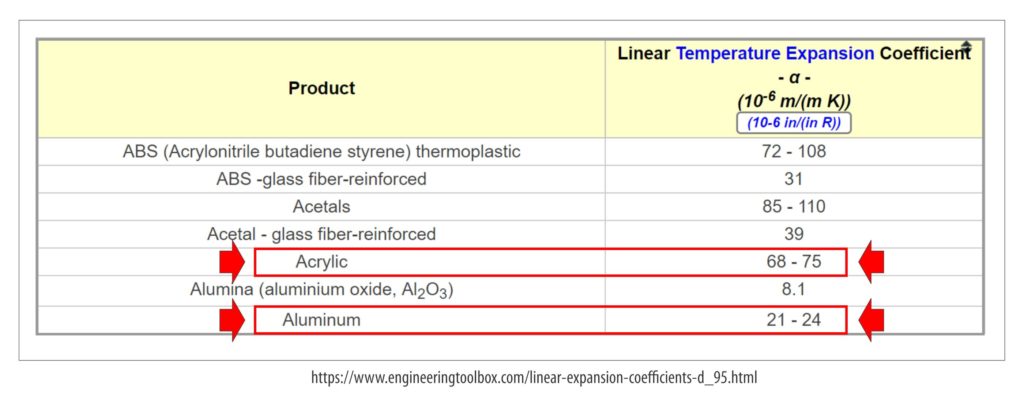

Here is a nifty chart I found from The Engineering Toolbox website that illustrates the huge differences between aluminum and acrylic.

Remember, the larger the material is and the bigger the surface area is, the greater the expansion when it gets hot. Whenever two large pieces of material must be connected, drilling oversized holes will allow each material to move a little, each independent of the other while still staying in place. In our industry, this occurs most frequently when dealing with aluminum vs. acrylic applications. As the chart shows, these are two materials with vastly different expansion rates.

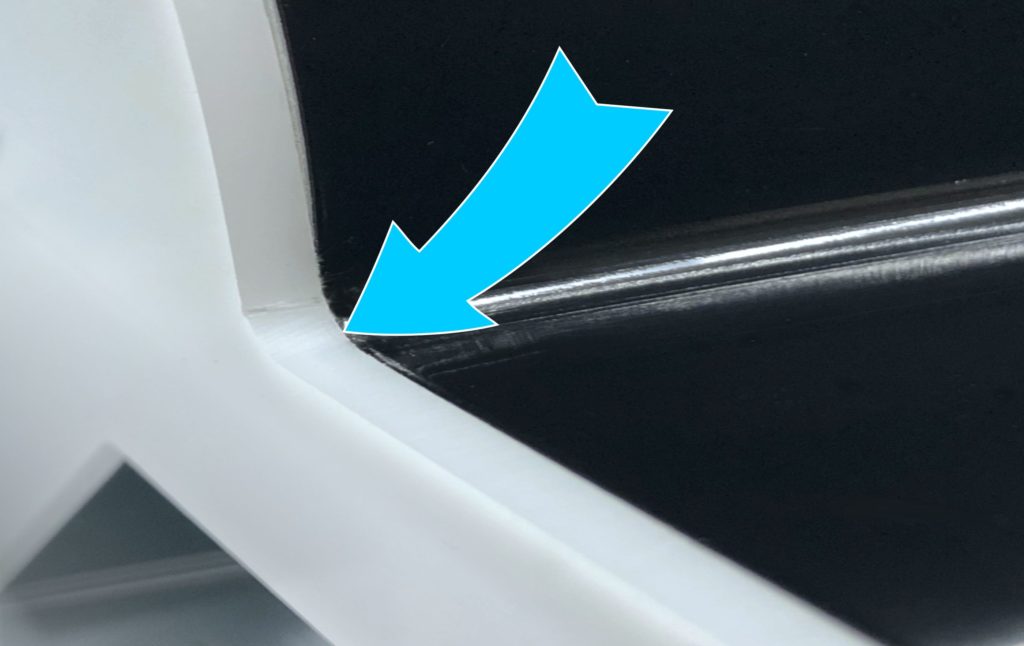

Everything gets hot in Texas

Once upon a hot Texas day, a sign was built and installed, and on the first day that the temps hit 115 F, the sign started to come apart. The acrylic backer panels popped off of the back side of the sign face because the inexperienced fabricator didn’t allow for this specific acrylic vs. aluminum expansion. It’s an easy thing to overlook if you do not have heat issues to contend with. The only technical mistake made by the fabricator was he left the acrylic nowhere to expand to. The sign was built with the backer sheet of acrylic being “fit tight” in-between the two vertical supports of the internal framework. The photo doesn’t show all of the damage, but as you can imagine, it was not a good day for anyone.

If that sign was anywhere else in the country and temperatures stayed under 100, it probably would never have been an issue.

Fans were needed

Heat also affects operating temperatures inside of large monument signs such as a dual pylon sign I designed several years ago. In this case, the temperatures got so hot inside the structure that large fans were installed to move the air through the space between the two giant EMCs. The temps inside that structure, with two large black surfaced signs that themselves generate a fair amount of heat, can make working conditions unbearable. So, accommodations for heat were made.

Vinyl application on hot days

When it comes to working in the heat, the best strategy is:

“Proper planning on the day before the job is to be installed,” according to Morgan Charboneau, a vinyl and wrap installer from Colorado. “… and the heat of the sun isn’t always a bad thing because it can be used (as a tool) to make the old vinyl on a truck box softer and easier to peel off. I’ve even let the sun help me set the memory on my wrap.”

Trying to apply a wrap on too hot of a surface can be disastrous as shown below, so again, good planning is the key. “If it’s going to be hot and it’s an outdoor install, you may have to start super early, like as soon as the sun is up to get it done before it gets too hot outside.”

Morgan says good communication between the customer, the scheduler who is setting up the installation, and the production team is vital. If it’s going to be hot, the temperature should be automatically part of the discussion, and part of production’s understanding on how to care for the vinyl prior to installing it.

“How you store the vinyl graphics prior to install is critical on hot days” Morgan says. “Rolling up a large digital print is fine if the temperatures stay normal, but if that roll gets hot, even for an hour while it’s sitting in the van, the transfer tape can shift, making it harder to install. If it’s going to be hot out, keep prints flat till they are installed.”

Black surfaces

Then there is the customer who insists on building a brand based on a black background for their logo. In Colorado or anywhere that the UV is intense, along with the heat, it becomes instantly clear that using a black background for a sign in a hot climate is basically nothing more than applying vinyl to a frying pan.

The client in this case had five locations that all needed a new black background sign, and previous attempts with vinyl proved to be disastrous. Hand lettering was the only viable option for this set of signs that after install were mostly pointing south, so they got really hot during the day. Lettering enamel held up to the scorching surface temps.

Channel letters

Trim cap is a component of a channel letter that holds the acrylic face to the aluminum return. The plastic used for trim cap must be able to stretch and expand with the aluminum. Unfortunately, this flexibility of the material in the heat also causes it to break down over time, forcing costly replacement of the trim cap, and sometimes also the acrylic letter face.

One solution to this is the use of a channel letter that uses a unique acrylic face attachment method, such as a trimless channel letter from SDS Automation, which eliminates the need for plastic trim cap. The letter shown below can withstand the heat and cold without the need for trim cap replacement down the road.

I’ve touched on how advanced planning around the heat is vital to getting the project finished on a hot day. When considering large properties in heat-challenged areas of the country, such as shopping centers where channel letters are incorporated into the entire sign program, the use of a channel letter without trim cap can potentially save the property owner thousands of dollars and weeks of parking lot inconvenience down the road. When comparing the cost of a trim capped letter vs. a trimless letter, or when using any material that has a known temperature mortality, the future replacement/repair costs should be considered. Why not plan to avoid that future expense and hassle?

Using a trimless channel letter is one way to successfully plan around the heat issues. Another is to plan your day around the sun and expect to be at the job site, with headlamps before the sun comes up. This may be the only option you have to get your installs done before it gets too hot to work.

Planning is really it. If you plan, if you communicate, you can work around the heat.