Before the COVID-19 pandemic, the promotional world was experiencing drops in quality, pricing spikes, stock shortages, increased production times, and more. We kept finding ourselves having to replace promotional orders with other in-house products to keep our customers happy due to the failures of those to whom we were outsourcing. Last year, I did the research and decided to take some of the control back.

Selection & installation

I researched a few different companies for UV printers and settled on LOGOJET. Merrie and her team did a great job through several meetings about their equipment. I explained to them our needs, such as what we were looking to produce, production times, cost per print, print quality, tech support, and more. You may find that an entirely different manufacturer best suits the specific needs of your shop.

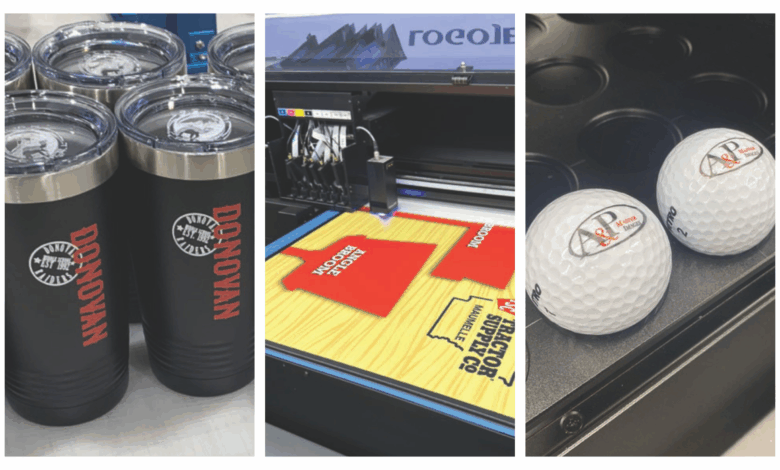

Once LOGOJET answered all our questions, we pulled the trigger and ordered their UVx90R UV printer. Why? It has a 24” X 36” flatbed that can print on items up to 6” in height. The quality of the components, in my opinion, is top notch. A rotary attachment prints directly onto round products. The UV printer can also print directly flat items and you can print UV transfers and hand-place them as needed. In my opinion, the best part about buying this machine from them is that they offer a three-year warranty.

When we received our machine, it was well packaged. It only took us around two hours to uncrate it, put the metal base together, and put the UV printer on top of the base. I suggest having four people to lift the UV printer to be safe. We purchased two flat wooden dollies to put the machine on its side and wheeled it in. We then put it onto the metal base we had assembled.

Training & costs

Once we had everything set up, the manufacturer’s team emailed us links to watch videos on maintenance. We set a date with them to send a tech out to get our machine up and running. They also trained us on operating the machine. If you you do this, I suggest setting up a camera to film everything. Is the machine hard to learn? Not really, but the RIP software and UV printer have a ton of capabilities to really print on almost anything. I suggest having a tech there for a third day to get in even more training upfront.

Every one of us has different goals, products that we sell, and customers with different needs. So, when I ordered our machine, I ordered a few different trays. I ordered one that could print on poker chips and golf balls. Other attachments allow me to print on drinkware 360 degrees. Another attachment that can print on 2” X 3” flat items that fit in each tray slot. The bed of the UV printer can hold three trays to handle more of the same item.

I suggest starting out with one tray for an item, so, in our case, we purchased several trays for different items to build demand first. As demand grows, buy the extra trays for those items. For example, the golf ball/poker chip tray can hold 72 pieces on one tray. If your demand for those two items increases, you can invest in two more trays and increase capacity to 216 pieces to make use of the full UV printer bed capability and just walk away and do something else while it is operating.

What have some of our costs been so far? Before I give you those numbers, remember that your artwork quality and the quality print you are looking for can all change the variation of your cost. When we print, we always make sure our artwork quality is top-notch and that we are printing at a mid- to high-quality level.

Costs:

- With full-color printing edge to edge, we got it down to 68 cents per side of a 18” X 24” yard sign, and we average around 16 one-sided signs per hour for the quality level we are seeking. You can get more if you adjust settings. That equals eight double-sided signs per hour times eight hours per day, which means 64 yards and has us producing them for $3.18 to $3.50 at cost before our mark up.

- UV transfers you will print white, full color, and clear, so those UV printers are a hair slower, but yield so much value. The average UV transfer you print costs you 1 to 5 cents per transfer. These are a huge game changer. Average transfer size is 1” X 1” to 3” X 3” imprint size and you can easily print 200 or more per hour. Again, this is based on size and the print quality you are seeking.

- Golf balls are easy money for production, along with poker chips. A golf ball has around a 7/8” or smaller imprint space and literally costs you 1 cent to print per ball and you can print 300 per hour if you have all three trays. We can easily print 216 an hour with one tray.

Why am I telling you all of this? Over the next five years, 70 million baby boomers will reach retirement age. That means roughly 11,200 people per day could potentially be retiring, while we are only birthing 10,000 per day. That means the potential of a lot fewer employees and we already know we are lucky if we have 400,000 people in the U.S. that do any of the customizing processes at all. That means fewer employees for both small and large companies, meaning you may not be able to rely on larger companies to outsource to as you could in the past.

Manufacturers will feel the squeeze with employees as well and they will only be able to handle so much work per year. They will have to make the choice of how many wholesale customers they will take on per year or they will go direct to the end users and shut down wholesale printing all together to maximize profits. For them it is a win-win situation because they maintain control.

All of this is positive no matter how you look at it. Even right now we do not have enough people in the U.S. producing in our industry, which means demand is extremely high and we all no longer need to fight to be the cheapest. This means taking care of your staff. Investing into them with full benefits as you are investing into this technology that streamlines your entire operation. If you take the next five years to do this, you are setting your company up for success no matter the size of your company.