As the digital evolution continues to disrupt the longstanding traditions of the sign making world, there are still a few product categories where old-fashioned, craftsman-styled work can have its place – and be profitable, for those who know how to work a niche.

Screen printing once formed the backbone of the pre-digital sign-printing industry, with skill and artistic flair the name of the game. That’s the environment Mike Hodgins remembers as a child, watching his father do screen work in the family’s print shop in Batavia, New York, a venture his father established in the late 1950s.

Hodgins still runs John’s Studio Wholesale and has managed to keep the screen-printing segment both relevant and business-worthy, integrating his small shop’s hands-on screen work with a range of new digital equipment to diversify his offerings.

“We still do a lot of traditional screen printing, as that’s been our old core business, but we’ve supplemented things with additional digital capacity,” he explains.

“Sooner or later, I expect that screen printing will go away, but in the traditional commercial market, offset printing is still the prominent process. It may be smaller, but I expect there will always be some work.”

Hodgins says the sweet spot for him and a handful of other regional wholesale screen printers is still the lawn sign niche – those durable and visually impactful, low-cost signs pitching lawn-care companies or political candidates. They’re certainly not high-tech products, but with simple color processes and inexpensive substrates, they’ve remained a profitable product to focus on, even today, as long as they’re part of a broader range of weekly print jobs.

He’s used a modest suite of modern equipment and the power of two-day shipping to sell a considerable volume of the lower-tech signage, volume being the biggest key to screen printing’s survival.

“Digital still hasn’t been able to match what we can do for a high-production job, and speed of production is still the major benefit for screen printing. Most people who run like we do can turn out 300 or 400 signs an hour, and digital still isn’t there,” he says.

Screen printing also continues to be a healthy enterprise for Alan Le and his family’s Just Yard Signs business, based in Orlando, Florida. Just Yard Signs has capitalized on a largely online-based market for inexpensive signage, using 4-millimeter corrugated plastic substrate and a website full of user-friendly templates to attract regional and national clients.

Le says speed and ease of production are still the format’s core advantages, allowing him to offer real estate or political campaign signs that are splashy but simple.

“Screen printing is faster, its ink is glossier, and the cost is less expensive if we do one-colored images – two-colored jobs cost more,” he says. Digital printing, by comparison, produces matte finishes and tends to cost more, though prices all even out in three- or full-colored sign projects.

Le says he works to keep Just Yard Signs’ prices competitive and focuses largely on fast turnaround, with package specials and products that also include aluminum signs, car magnets and vinyl banners, produced on his wide-format equipment.

For Hodgins and his six-person team in western New York, the basics of screen printing have not changed a lot since the 1980s and the first use of photo stencils, a technological leap from the early days of real silk screens and the painstaking work of manually-cut stencils.

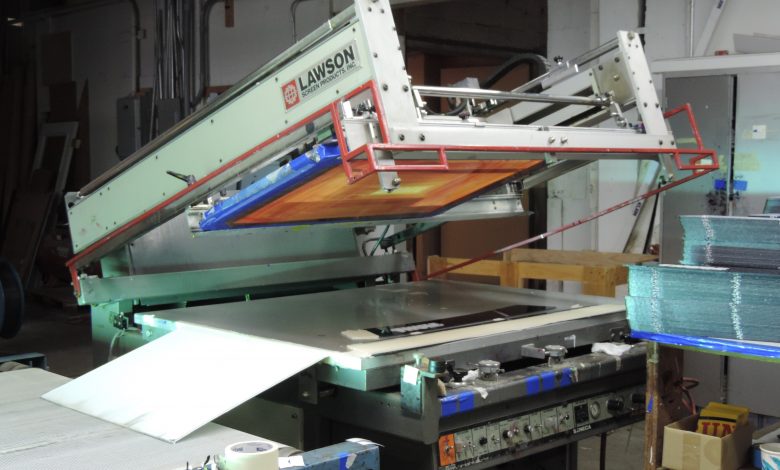

John’s Studio Wholesale uses a Lawson flatbed screen press to turn out its work, with UV-cure inks; Lawson and American M&M are still major providers for those looking for new screen-printing equipment, part of the smaller community Hodgins still represents when he goes to trade shows.

Screen printing pre-press work is universally digital, and once a client’s image has been checked and finalized, Hodgins’ staff starts with a positive film, producing an opaque, digital inkjet-printable film. A screen is then custom manufactured and then the images can be pressed and produced in bulk.

Screen printing is also adaptable enough to allow substrates metal, plastic or even wood substrates; by limiting the signs to one or two colors, costs are kept low and the products fly out the door. Hodgins also runs a unionized shop and can offer products with union-made labels.

Using UPS two-day shipping, Hodgins says he can provide prompt and affordable service to smaller sign shops along the Mid-Atlantic and New England.

Despite his enthusiasm for screen printing, Hodgins says he also has to be realistic when offering advice to anyone thinking an artisanal screen-printing venture might be a great new venture.

“I would just not really recommend getting into it at this point, frankly, especially not as a new, single business,” he says. “For us to survive, we’ve evolved and do a lot of other wide-format commercial printing. We’ve also gotten into offset thermography as a specialty market, in addition to selling directly to the trade. We’ve really branched out and found new niches.”

Potential screen-printing adoptees should also consider the seasonality of their products – those spring and summertime bursts of trade, lawn-care and contractor advertising, plus the short-term bursts of excitement during political campaigns – with some year-round opportunities in real estate.