If you are in the market for a new printer for your shop, one of the best options to look for is a roll-to-roll unit. Roll-to-roll printers provide a host of options for sign shops as these resourceful machines produce incredible quality at high production speeds while offering the flexibility to produce a plethora of jobs.

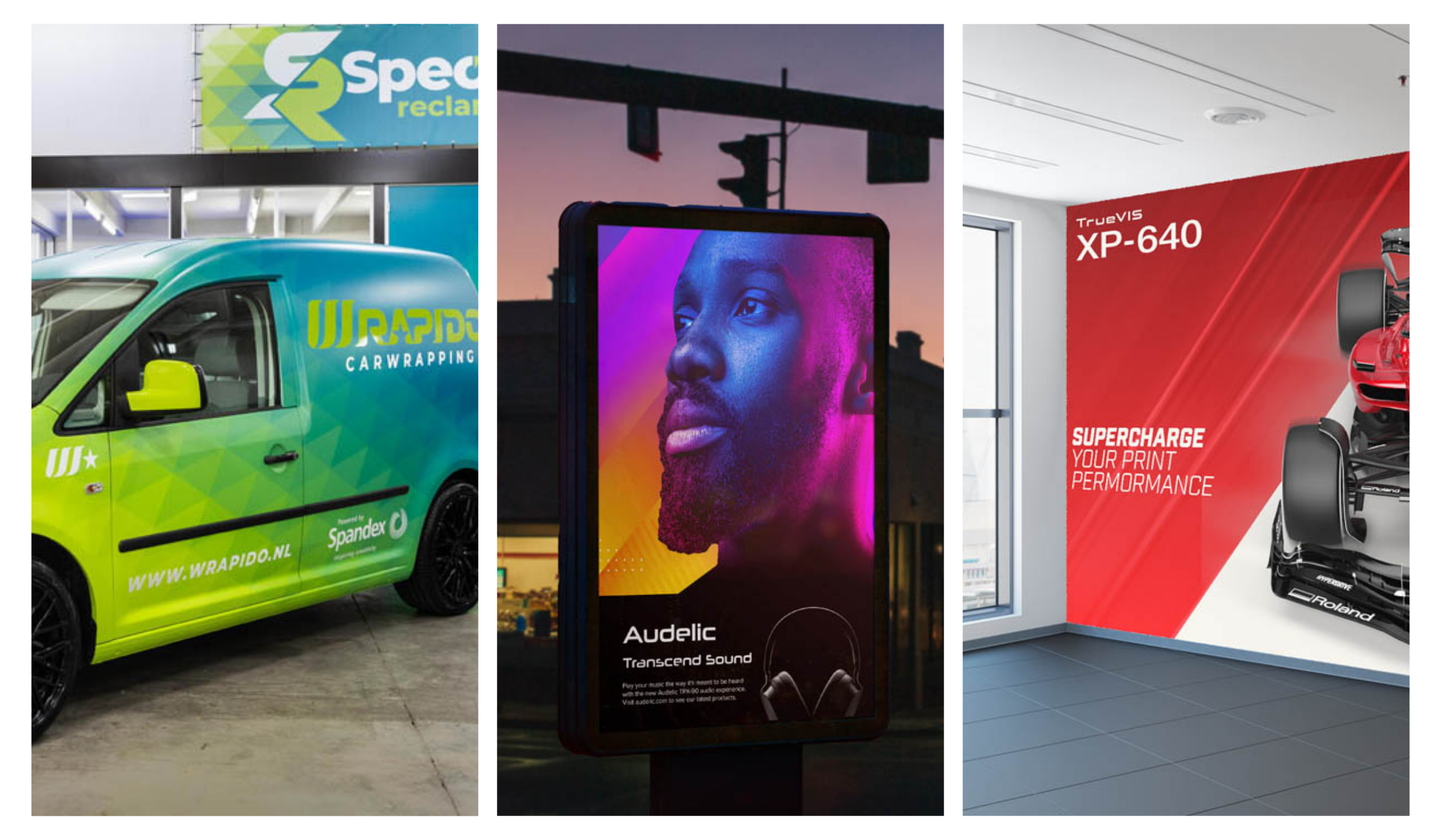

The total versatility of roll-to-roll printers enables different configurations with dye sub and textiles ink sets for the fashion apparel, home decor, flags and soft signage markets, as well as solvent and UV configurations for the sign and graphics markets and water-based ink sets for the fine art and photography markets, as well as vinyl and canvas banners to backlit signs and vehicle wraps.

We spoke to a number of suppliers and asked them what shops should look for and what things to consider when purchasing a new roll-to-roll machine.

More automated options

Patrick Donigain, senior manager, LFP Business Planning & Strategy Group at Canon USA, said the roll-to-roll printing market is seeing a strong push toward automation, versatility, and sustainability. “Printers that offer modular upgrades, low maintenance, and high uptime, while reducing operator interaction, are gaining traction. There’s also a growing demand for white ink capabilities and smart ink technologies that reduce waste and improve color consistency.”

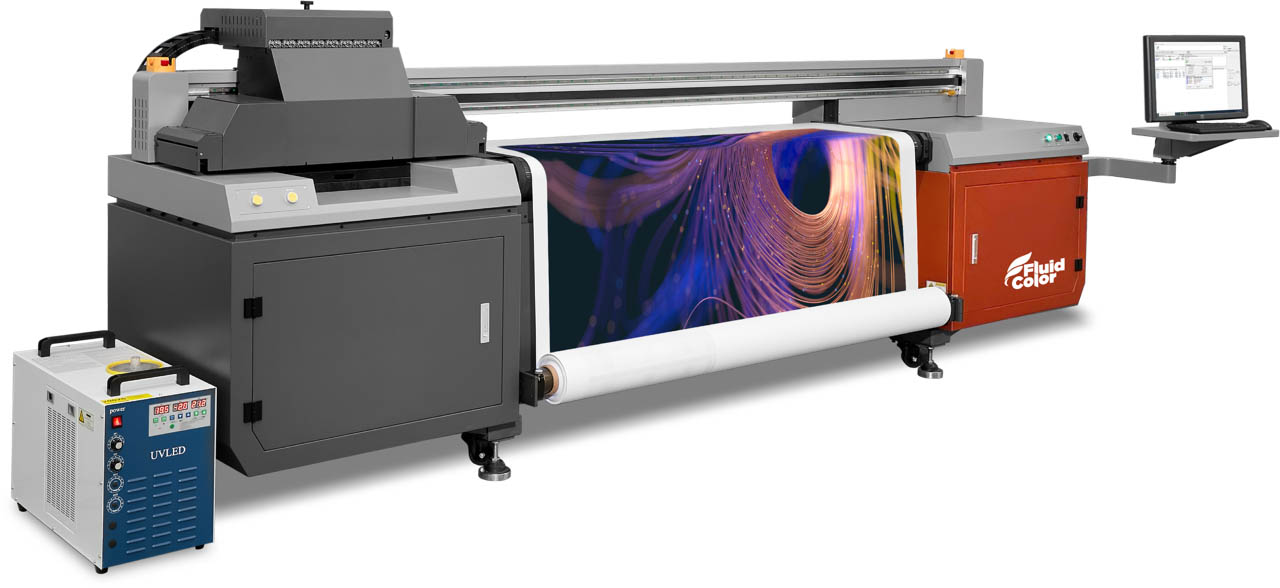

Jeff Dilley, regional sales manager at Fluid Color, noted that the biggest trends for 2025 in roll-to-roll printing continue to center around automation, versatility, and sustainability. “Customers are demanding faster turnaround times with fewer touchpoints, leading to the integration of automated take-up systems, in-line finishing, and advanced RIP software that allows for efficient nesting and job planning. Sustainability is also at the forefront, with eco-conscious brands seeking printers that can operate with low VOC UV-LED inks and energy-efficient curing systems.”

(Image courtesy of Canon USA)

Hybrids growing in popularity

Dilley added that hybrid platforms capable of both roll and rigid printing are gaining popularity. “This reflects a shift in the industry toward maximizing machine ROI by expanding a single printer’s capabilities. We’re seeing greater adoption of our UV LED roll-to-roll systems because of their ability to run extended shifts with minimal maintenance and handle a broad array of media types — critical for clients aiming to consolidate equipment and reduce overhead.”

Tony Simmering, product manager at MUTOH, said that the growth of the home or small-scale crafting market has opened an entire channel dedicated to people seeking a solution that is more advanced and more capable than something like a color-change vinyl cutter. “A big push is being made for products that offer multiple purposes, like printing and cutting,” said Simmering.

Surprisingly, printhead technology hasn’t jumped the shark yet and is advancing a ton in these last few years. We are able to produce much higher fidelity printers at greater speeds, using lower resolutions/pass counts. Another factor to consider is that these new printheads are much more robust than previous generations and become overall less of a burden for maintenance,” he pointed out.

Daniel Valade, product manager of digital print for Roland DGA, is seeing an increased user demand for roll-to-roll printers and printer/cutters that offer greater versatility, outstanding image quality, and increased production capability while keeping operating costs low. “When it comes to research and development, our focus has been on innovation that allows for a wider color gamut that expands creative opportunities and allows for improved color accuracy,” he said.

Advancements in technology

Dilley pointed out that recent advancements in roll-to-roll technology include higher-speed printheads, improved media handling with tension control systems, and enhanced curing technology using adjustable-zone UV LED modules. “These updates allow printers to produce vibrant, durable output at production speeds of over 4,000 square feet per hour, making them competitive with traditional analog methods in terms of throughput.”

Dilley said another key feature is the increasing use of variable drop technology, which allows printheads to jet multiple droplet sizes within a single pass. “This improves both the fidelity of fine details and the saturation of solid fills. Our roll-to-roll printers utilize advanced grayscale technology and multiple-row printheads to balance speed, price, and quality across diverse applications — ranging from high-end retail signage to long-run outdoor banners.”

Consider before buying

Donigain said some questions to ask and important points to consider include:

- Media versatility: Can the printer handle a wide range of substrates? Does the system allow you to use lower-cost media or novel media that expand your revenue streams?

- Ink technology: Look for low temperature curing and low VOC emissions, as well as whether it meets industry standards, without exceptions, such as Green Guard Gold, MCS, ICS, OCS, or ASTM type II.

- Operational efficiency: Consider automation features and unattended printing capabilities, as well as whether the printer ink combination eliminates the need for additional steps, such as lamination, or requires long drying times before prints are able to be laminated.

- Scalability: Can the printer evolve with your business needs? What is required to add capabilities or productivity?

“Printers that offer low total cost of ownership and minimal operator intervention tend to provide the best long-term value,” he pointed out.

Dilley explained that when considering a roll-to-roll printer, buyers should assess production volume, media compatibility, ink requirements, and workflow integration. “For example, if you’re working in environments with frequent material changes or short-run customization needs, you’ll want a printer with fast setup and intuitive RIP software that can streamline layout and color management.”

He said to also think about post-sale support and consumables. “Many lower-cost printers lock users into expensive proprietary inks or offer minimal service infrastructure. We build open, modular systems that are easy to service and run on high-quality but competitively priced inks — delivering lower total cost of ownership and less downtime over the lifespan of the printer.”

Valade added that first and foremost, before making any purchase, “it’s important to choose a manufacturer that stands behind the quality of the products they offer and will be with you every step of the way after the purchase to help ensure your ongoing satisfaction, growth, and success.”

Valade continued, “Equally important is to make sure you are investing in a versatile and reliable machine that will allow you to effectively handle the applications you’ll be offering, meet your production and turnaround requirements, and consistently deliver vivid, detailed, long-lasting output quickly and cost-effectively. You’ll want to invest in a technologically advanced, dependable, easy-to-use device that consistently prints high-quality, precision output day in and day out with minimal downtime.”

“After all, the name of the game is being able to meet or, even better, exceed the demands of your customers while achieving maximum profitability. That requires a device that will allow you to accept more jobs, quickly produce high-quality output, increase your production capability, meet tight turnaround times, and keep operating costs as low as possible,” stated Valade.

The price of ink in tough tariff times

Simmering noted that even though many manufacturers are willing to subsidize printer pricing in this (hopefully) short-term tariff volatility, something consumers need to look at is ink pricing.

“MUTOH manufactures our inks in Japan and anticipates steady ink pricing, so our customers have the confidence to grow with us,” he stated. “There is no perfect ink that does everything (no matter how much a sales manager tries to convince you otherwise).”

Simmering said that eco-solvent inks are traditionally the prime candidate for general-purpose signage like posters, banners, stickers, etc., as they have great outdoor durability and an excellent color gamut.

“UV roll-to-roll is becoming popular due to the capability to print with white ink, as well as produce embellishments like texture; the downside being limited outdoor use. Dye-sublimation is the ultimate solution for extremely durable long-term graphics like silicone edge graphics, metal panels, and trade show/event/brand signage.”

He added that MUTOH also offers a specialty “multipurpose” ink that allows for applications such as packaging prototyping and proofing on coated and uncoated materials, giving print houses, designers, and brands accurate color and finish capabilities without having to conduct large-scale press runs.

Advantages of roll-to-roll over flatbeds

Valade states there are several advantages that roll-to-roll printers have over other inkjet model types, like flatbeds. “While both roll-to-roll and flatbed printers deliver vibrant, detailed high-resolution prints, roll-to-roll models offer faster print speeds, job versatility, media flexibility, and cost-effectiveness. Roll-to-roll inkjets can also handle a wide range of flexible media (vinyl, paper, fabric, etc.), whereas flatbeds are primarily designed to print on rigid substrates and 3D objects.”

He continued, “The smaller size of roll-to-roll printers allows them to fit into many spaces that large-format flatbeds can’t, and the capacity of the roll media they use makes these printers and printer/cutters ideal for both short runs and higher-volume production. They can also run continuously and unattended, which allows for greater convenience and productivity, and they can be more cost-effective, especially when jobs involve large quantities of similar prints such as posters or stickers.”

Donigain said roll-to-roll printers excel in continuous production, especially for long runs of flexible media like banners, vehicle wraps, and wall coverings. “They typically offer faster throughput and lower media costs compared to flatbeds. Additionally, roll-to-roll systems are often more compact and easier to integrate into existing workflows, especially when space is limited. Printers that can handle multi-layer printing, including white ink on transparent or colored media, are especially in demand for these applications.”

Simmering pointed out that one of the biggest advantages that roll-to-roll has over other printing options is the ability to print large, continuous pieces. “Wrapping a city bus would be an extremely cumbersome job if it was required to panel out into a ton of pieces.” He added that vehicle and structural graphics/wraps, stickers, banners, posters, DTF apparel, promotional items, and cut-and-sew apparel are some of the top applications produced on these machines.

Dilley feels that roll-to-roll printers shine in high-volume, continuous print environments. “They are ideal for applications such as banners, vehicle wraps, and window graphics where roll media is standard. Compared to flatbeds, roll-to-roll systems offer faster throughput for flexible materials and lower media waste since there’s no need for masking or taping media onto a vacuum bed.

“Moreover, roll-to-roll platforms often have a smaller physical footprint and simpler loading/unloading workflows, making them ideal for production environments where space and speed are priorities. While flatbeds excel at rigid substrates, a well-configured roll-to-roll printer can output thousands of square feet per shift at a fraction of the operator labor and media prep time,” he said.

Dilley explained that popular applications for roll-to-roll printers include soft signage, window graphics, wall coverings, vehicle wraps, event graphics, and backlit displays. Additionally, many clients use roll-to-roll printers for short-run packaging prototypes and personalized promotional items. The versatility of these systems — especially when paired with white and varnish ink options, opens up opportunities for specialty graphics with high visual impact. With the rise of e-commerce and short-run branding, the need for versatile, just-in-time production capabilities is higher than ever.”

What is the best ink type?

Valade said whatever roll-to-roll printer type you choose to go with, it’s important to use OEM inks that are specially formulated to bring out the best in that type of machine. “Each ink type has its own distinct advantages for specific applications.”

“For example, eco-solvent inks offer excellent print quality and outstanding outdoor durability; latex inks also produce vivid, detailed prints, but are more environmentally friendly, allowing them to be place in sensitive spaces like hospitals or schools, and require less outgassing time before lamination; UV inks don’t have the same durability and stretchability as eco-solvent inks, but they image beautifully as well and dry instantly under the printer’s powerful UV light.”

Valade continued, “Plus, they allow for gloss ink printing effects that add dimensional effects to prints; dye-sublimation inks are better for printing on fabrics and textiles as they soak into the fabric instead of chemically adhering to the surface. Each ink set has its pros and cons, depending upon the applications the print provider wants to offer.”

What’s the application?

“The best ink really depends on the application. For general signage and outdoor durability, UV-LED inks are the top choice — they offer excellent adhesion to a variety of substrates, low curing temperatures, and instant cure times, which means faster finishing and no off-gassing delays,” said Dilley. “We exclusively use LED-curable UV inks because they offer vibrant color, durability, and eco-friendly benefits like low VOC emissions and energy-efficient curing.”

“For textile applications, dye-sublimation remains the preferred option due to its color vibrancy and wash resistance, but it does require coated polyester and a separate sublimation process. Solvent and eco-solvent inks are still viable for some outdoor graphics, but they often come with higher VOC emissions and slower dry times compared to UV-LED. Latex offers a middle ground with water-based chemistry and environmental certifications, but printhead lifespan and maintenance costs remain considerations,” Dilley added.

Donigain noted that each ink type has its niche. UV gel ink is gaining attention for its instant drying, low-temperature curing, and exceptional durability. “As the newest class of large-format inks, it is known for its vibrant color, scratch resistance, and efficient ink usage. These qualities make it ideal for both indoor and outdoor applications, often eliminating the need for lamination. Solvent inks are a great solution for applications requiring extreme stretch, while latex inks can offer certain safety advantages in their uncured form compared to solvent or UV inks in their uncured states.”