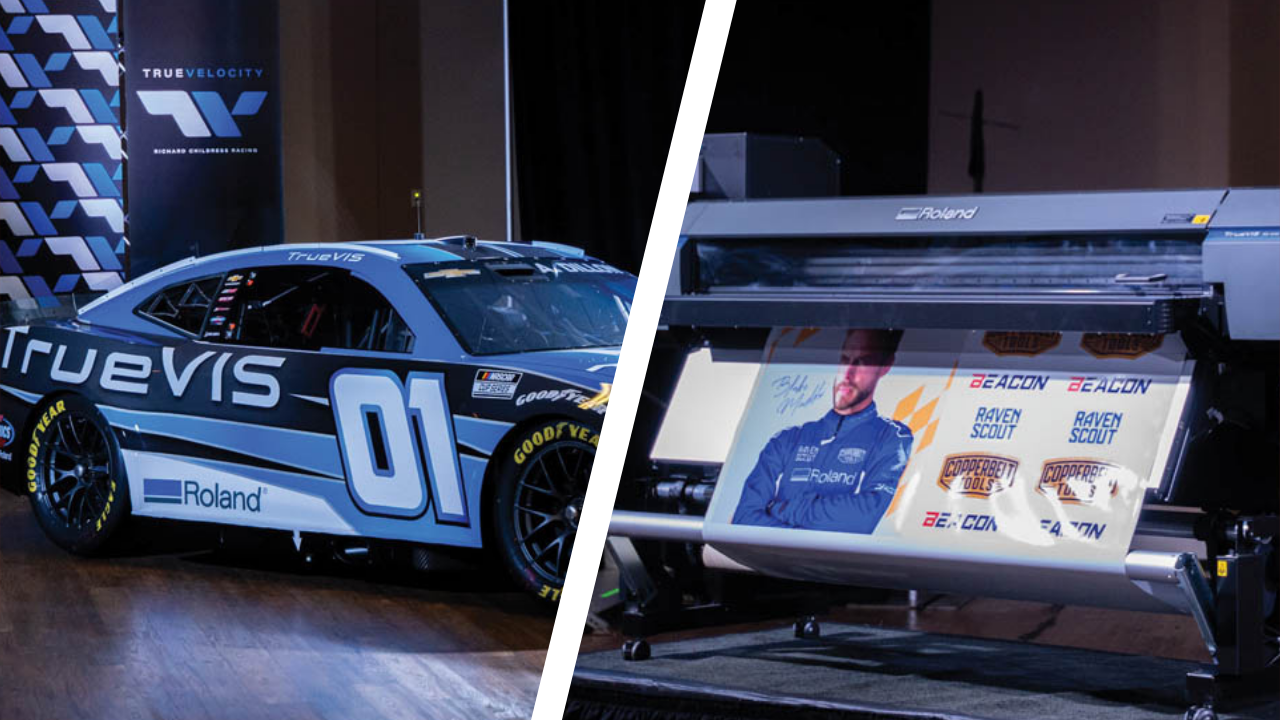

Roland, race cars & wraps at true velocity

Roland DGA showcased its newest wide-format printer/cutter at the Richard Childress Racing campus & we delved into the partnership between the two companies.

Roland DGA has continued a proud partnership with Richard Childress Racing (RCR) since 2010. Located in Welcome, North Carolina, the RCR Graphics Center is powered by a full lineup of Roland wide-format printers and cutters. Here, RCR Graphics Center staff designs, prints, and wraps RCR’s NASCAR race cars before each race — including the backup race cars, transport vehicles, trailers, and pit-support equipment.

This fast-paced, performance-driven environment is where Roland DGA held its TRUE VELOCITY event, at which Roland DGA resellers were given a sneak peek of the company’s newest addition to its large-format eco-solvent printer/cutter family: the TrueVIS XG-640. Stated as being Roland DGA’s “fastest, most capable printer/cutter to date,” it stands to reason that the RCR campus is where the printer would make its debut — and will find a home at work in the RCR Graphics Center.

During the event, attendees were given an up-close look at the XG-640 while it printed — as well as previews of the newest versions of VersaWorks 7 and Roland DG Connect. In addition, attendees took guided tours of the RCR campus, including the RCR garages and workshops, the RCR Graphics Center, and the RCR Racing Museum. Activities included driving simulators, track pit stop demos, and wrap demos.

To get a better understanding of Roland DGA’s history and relationship with RCR, we sat down with Andrew Oransky, CEO of Roland DGA.

Q: How did this partnership come about?

A: Back in around 2010, there were a couple of very large graphic shops in this area, and one in particular that was basically doing all of the graphics for all of the race teams. So, the race teams were outsourcing it. This was also the early days of wrap technology — the equipment in the early 2000s was more expensive, took up more floor space, was more difficult to use, and required more expertise. And so, you had a couple of these companies that had developed the infrastructure, the equipment, and the expertise to do it.

Nick Woodward, who is a former racer himself, wanted to stay involved in the industry after he quit driving, so he was working at one of those shops. And he had gotten to know Richard [Childress] through his history as a driver. And at some point, [he] went to Richard and said, “You know, I’ve got this idea to move this in-house because I think that there’s more flexibility doing it in-house.” There’s obviously a bit of a cost advantage. The big thing was the speed and being able to change designs, alter designs, and redo cars. These cars take a beating on the track.

At that point, they went looking around for technology and came to us and said, “Hey, we, we’d love if we could form a partnership where Roland DGA gets a sponsored credit if you can outfit our graphic shop.” And so they were the first team to take this internally. For those 15 years, the RCR graphics production department has been co-branded with Roland DGA. It’s been a great partnership. Subsequent to that, almost every other major team has brought their graphics production in-house.

Q: What does the partnership entail?

A: We provide hardware and expertise to the shop. In addition to that, Nick and his staff have made themselves available to us for a number of things. First of all, when we’re launching new products, we have him take a look, and we want to make sure that they suit the needs of a production wrap environment. Nick and his staff help us out with evaluating equipment. He and his staff are incredibly generous with their time. It’s just been a really great collaboration.

We have used this facility, [Richard Childress Racing], for a number of our wrap classes and training. We’ve also had, at various trade shows, NASCAR race cars in our booth doing live wrap demonstrations.

Q: How has the partnership grown and changed over the years?

A: It started with a lot of uncertainty. For a race team to take this on was a really new idea at that point. Back in 2010, a lot of what we were doing was just validating the idea of even doing this in-house. It’s turned out that over time, part of what he’s learned — and we’ve learned as a result — is that there are some actually fairly specific techniques and methods to wrapping in this industry that people who wrap cars on a commercial basis would never get involved in. So there’s been a tremendous amount of learning how to perform that function within the sort of constraints and requirements of a race team.

But, it also started very, very small. At the time it started, there was one printer, one laminator, and a worktable. And it’s kept expanding to the point where there are [multiple wide-format] printers in there at this point, [including] a couple of cutters, [and] more than one laminator.* They’ve just continued to expand the range of applications.

Q: What has been your favorite aspect of the partnership with RCR?

A: The insight that it’s offered to our entire business. Our growth over the years has really revolved around creating new applications and new opportunities for customers. Dan Johansen and Dan Burmeister both talked [during the presentation] about the idea that our commitments and our outlook really is to help our customers be successful in making money.

And in order to do that, we need reference customers, we need partners, we need people who are going to teach us how different kinds of businesses actually use our equipment day to day, so that we can, frankly, speak intelligently to other people in that industry about why they ought to be using our stuff. So, it’s really just expanded our outlook into what these folks need and what they do. It’s helped inform some of our decisions on how we position certain features.

Of course, having our name associated with a historic organization like RCR in general has had great marketing benefits for us. The cars draw a crowd when we do those demos at trade shows. When we’ve done training down here, they always sell out because people want to come here and see the place and be associated with it. And those have all been very specific benefits.

Q: Do you have a favorite race car wrap that’s been produced by the RCR Graphics Center?

A: Particularly, in the Xfinity series, when for one reason or another, RCR had not had a hood sponsor, and we had the opportunity [to use that spot]. It was just so cool to turn on the TV, and my kids were like, “Wait, what’s that? I know what that is!” Watching it do burnouts in the victory lap was cool.

Q: What else should our readers know about the partnership/RCR/etc.?

A: I would like readers to know that, if they are a wrap shop, if they are thinking of opening a wrap shop, or even getting into this [i.e. wrapping race cars], if they want to talk to someone who’s been there, we can make these people [RCR Graphics Center staff] available to them. We have this expertise, and Nick and his crew love to talk about what they do.

I think that’s maybe, to some extent, the underutilized part of this partnership. I would love for Roland DG users or potential Roland DG users, or people thinking about making an investment for their business, to talk [with them] about how this technology fits into an environment like this. And these folks are absolutely available to do that. If somebody reaches out to us, we can make that connection.

Thank you to Roland DGA & Richard Childress Racing for their hospitality and time during the event — we’re looking forward to seeing what graphics shops around the country will create with the TrueVIS XG-640.

*Editor’s note: According to Nick Woodward, RCR Graphics Center manager, the team primarily uses the following Roland DG printers and cutters to print wraps and other vehicle graphics for their race cars:

- TrueVIS VG2 large-format eco-solvent printers

- TrueVIS VF2 large-format eco-solvent printers

- GR2, GR, and GX series large-format cutters

- And now the new TrueVIS XG-640

They also have additional Roland DG devices in the RCR Graphics Center that they use for creating labels for the Richard Childress Vineyard, promotional signage, banners, etc.