Rock the Volt: The Many Choices in Powering LED Signage Systems

The many choices in powering LED signage systems, from source to set up.

We as human beings love having options available to us. They come in many different forms: colors, sizes, costs and more. Having options keeps businesses running at a healthy level and allows for product improvement to take place. Think about the ongoing battle between soda pop manufacturers and how low-calorie options, flavor enhancements and caffeine-free (or caffeine-loaded) beverages have flooded the market. It gives consumers a sense that they have control over what they are purchasing.

The same can be said in the sign market. With illuminated signage, there is certainly a range of lighting options available. If a customer wants to include LEDs in a project, there are several sign shops and manufacturers that would be happy to provide the products and services. Moreover, these products can be tailored based on the customer’s budget, usability and location.

Power is another important consideration, and with LEDs, voltage is a topic to address. Specifically, how much voltage is needed to power an LED sign? The two main options-12-volt (12V) and 24-volt (24V)-both have their place in the market.

“NEC Class 2 power supplies can have 100-watt (W) output with 24V instead of being limited to 60W with a 12V output,” says Mike Bluhm, director of global product solutions at Sloan LED. “This allows you to get more product on a power supply.”

But that’s just the tip of the iceberg when discussing voltage options. To paint a better picture, we need to address the differences between 12V and 24V, the benefits of both and the other elements that go into the LED sign.

Differences in Voltage and Usage

Using the most basic analysis, a sign’s location, intended function, and general design will dictate how much voltage to use.

“A 24V carries more power, therefore will produce more light,” says Christina Farmer, director of sales support, US LED. “Some LEDs only work with 12V and some only work with 24V.”

Popular thought tells sign makers to use lower voltage with channel letter projects and higher voltage in more demanding projects.

“For everyday channel letters, there is really no need to pay a premium for a 24V system,” says Bryan Vincent, partner, Principal LED. “In linear systems, like our Street Wrap II, a 24V system is preferred due to the long run lengths. In sign cabinets, it depends on where the power sources need to be mounted and really comes down to an overall system cost.”

With channel letters and sign cabinets being two of the most popular LED applications, voltage becomes a question during design and implementation stages.

“Channel letters are more often than not one- to three-stories high before you have to really worry about brightness being an issue,” says Farmer. “You want more efficient modules that are bright for channel letters. Conversely, cabinets typically require significantly more modules, have the potential of being hundreds of feet in the air, and need to be illuminated in such a way that makes it noticeable to pedestrians on the ground. To achieve this, we want a module with more lumens which requires more watts per module and more space on a power supply.”

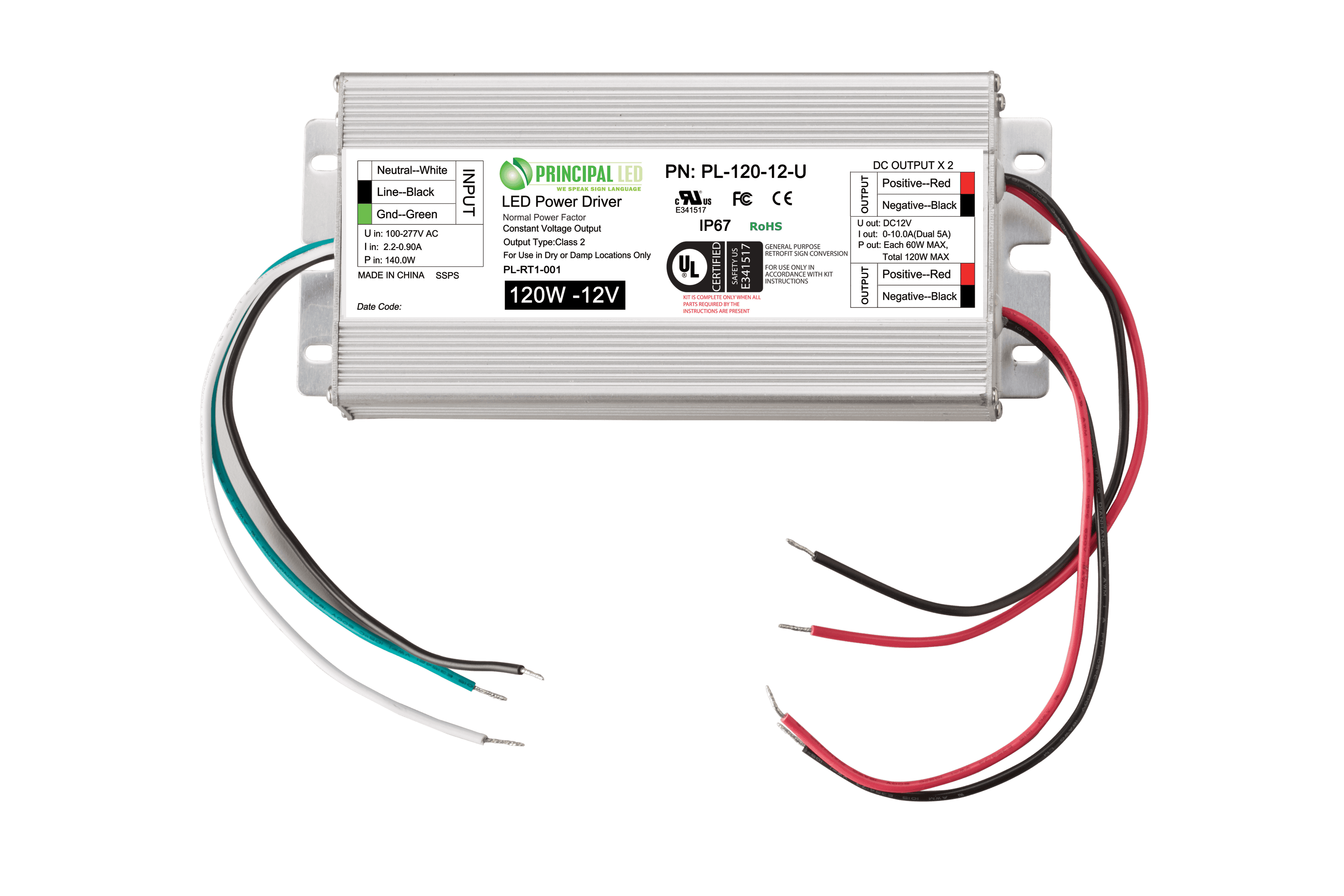

The power supply is also a point of consideration, which will ultimately serve as the driver of the LED lighting that regulates the power to the LEDs.

“With 24V, you could benefit from the fewer power supplies or when a higher efficacy is demanded from the end-user,” says Bluhm.

And Rob Riley, sign channel territory manger, Keystone Technologies shares that “depending on how big the channel letters, and if you want a power supply in each letter, (that) may lend to a 12V system.” But as a general rule, “The systems out there pretty much determine what voltage their products run on,” Riley continues, “so, if you are lighting a product that requires 12V you would use a 12V power source, and if your lighting a product that requires 24V you would use a 24V power source.”

Other components of the lighting system, such as the diodes and actual design of the system can contribute to the voltage decision. According to Vincent, “It is important to note that whether the system is operated at 12V or 24V, most LED chips operate around 3V. Sometimes, the LED manufacturer will put multiple chips in series or sell a multijunction LED (for example three chips in series to create a 9V LED lamp). Modules are designed by creating a series combination of lamps to achieve a desired input voltage. There is no fundamental efficiency benefit between a 24V versus a 12V system.”

Efficiency is a regularly addressed topic in LED sign projects; however, Vincent notes that higher voltage does not directly contribute to a more efficient system.

“In fact, the highest efficiency white LEDs (above 200LM/W) are typically at or below 3V operating voltage,” he continues. “At Principal LED, we developed a new Stik product that utilizes one of these special LEDs to create a new 12V retrofit Stik that is 10 percent more efficient than the most efficient 24V systems. It all comes down to system design. The idea that a 24V LED system is somehow ‘more efficient’ than a 12V LED system is simply a myth.”

Bluhm contends, though, that “On 24V modules, it is possible to get more LED chips in series depending on how the LED forward voltages add up. More LED chips often translates to more light output with the benefit of not using additional power with fixed voltage output power supplies.”

System Elements

It is evident that more than one factor goes into determining the LED system configuration. As mentioned earlier, sign shops will need to take many things into consideration when offering a solution for customers. Below are a few major elements that will come into play.

Pricing

Oftentimes, this is the most important question on the mind of the customer. Budgets can dictate purchasing decisions and sign makers ask customers what they are willing to spend on a project.

Bluhm states that, “With 24V products you would see the module cost typically higher as they require more LED chips efficiently run within 24V.”

That number for 24V power supplies and LED modules could be “between 30 to 40 percent costlier than a typical 12V system,” says Vincent.

In dollars and cents, Riley suggests that “Depending on model(s) and brands there can be a price difference anywhere from seven up to 20 dollars more for a 24V power supply over the 12V power supply.”

On the face it appears that 12V solutions are much less expensive than 12V options, but there are also long-term factors.

“There are price differences for the two as the 12V requires less energy than the 24V,” starts Farmer. “However, depending on the application, if the sign company is overloading the channel letters or cabinet with 12V modules and power supplies to achieve a certain look, they can be saving money by using a higher powered and brighter LED with less 24V power supplies and the project cost less.”

Design

With respect to the LED system design, there can be differences between 12V and 24V options.

“There are many designs as well as many ratings such as Ingress Protection (The IP rating) that play a big role in price and what you should use in your particular application,” explains Riley. “Such as ‘Do you want couplers or do you need couplers?’ ‘Do you need a dust and water rating for the elements your application requires?'”

The size in the sign’s design can also play an important role.

“When looking at large signage,” Bluhm starts, “one needs to think about the amount of power supplies needed. With 24V, you would have fewer units to position within or near the sign.”

Farmer adds that “The stroke and depths of a letter are easy ways to figure out if either 12V or 24V products are the better option.”

Lifespan

Generally, LEDs are a trusted source when it comes to dependability and long-lasting performance. Any LED system should last much longer than older options.

“All of our products have a long lifetime to ensure we are market leaders in that regard,” says Farmer. “The cabinet modules, specifically, are modules we ensure have a 200,000 L70. Our reasoning is that if a sign company is leasing signs or tenants are only wanting to replace faces then they have a solid product installed that will last longer than it will be installed. To pair with long lifetime modules you must have power supplies that are top-quality.”

When it comes to the voltage, “Life expectancy is no different in 12V versus 24V,” says Riley. “Ideally the power supply should last as long as the sign. The industry standard as far as warranty is still five years although there have been a few companies that have stretched that a bit further with limited warranties.”

Vincent agrees that there is no discernable difference in the life of 12V and 24V options. “Assuming the actual LED chip in the module is operated at its intrinsic voltage and the same power,” he says. “there should be no lifetime or performance benefits to either design.”

Power Supply

As addressed previously, the power supply is a critical element to the entire system. That said, sign makers should know what options are available with both 12V and 24V systems.

“As far as manufacturers there are many options available in both 12V and 24V,” says Riley.

But when comparing one versus the other, “Typically there are more options commercially available in the sign industry at 12V versus 24V,” Vincent shares.

Again, 12V options pair well with channel letter projects so “With 12V, you could benefit when the sign doesn’t require a substantial amount of lighting,” says Bluhm. “Small channel letters that only need one power supply would be a good candidate for 12V LED products.”

Riley concludes that with “A UL Class 2 power supply you will be running an output of 60W or less on the 12V system and 96W or less on the 24V system.”

This brings us to the topic of “maximum run” in relation to voltage.

Maximum Run

“Assuming the same efficiency, you can run 60 percent more modules per channel,” says Vincent. “However, at Principal LED we have looked at competitive costs of a 24V, 96W single channel power supply, versus our 12V, 120W dual (2x60W) channel power supply, and the costs to the sign maker are very similar.”

The balance of power (or quality, in some cases) versus cost will come up in discussions of maximum run. Vincent explains that in his experiences, “you actually end up being able to ‘run’ 25 percent more modules on the 12V system at the same cost. In addition, both systems have one primary hook-up, so you actually end up making fewer primary hook-ups with the 12V dual channel system.”

When calculating maximum run for 12V and 24V options, “You have to use a little math here,” says Riley. “Figure out how many watts the product you are using needs to run using the specs from that particular product and do not exceed that number.”

Conversely, “The minimum is not usually a factor,” Riley continues, “however (it) needs to be looked at if you are lighting a dot over an ‘i’ or using less than five watts or so as a rule. If you are lighting a small area you will need to find out the minimum output for that particular power supply 24V is usually a little higher than 12V.”

Other Options

Sign makers may encounter other options outside of the 12V and 24V systems, however, “they are typically around specifically designed luminaires,” says Vincent. “The 12V or 24V systems represent 99 percent of the signage systems in North America.”

Historically, a handful of choices have been available on the market at one time or another. Bluhm recalls, “(for) our first channel letter module system in the early 2000s, we had 7.5V, 12V, 24V modules and 8.2V briefly. However, we learned that that was too many power supplies and we centered around 12V and 24V pretty quickly.”

Even today, in retrofit projects or other replacements, there might be some additional options.

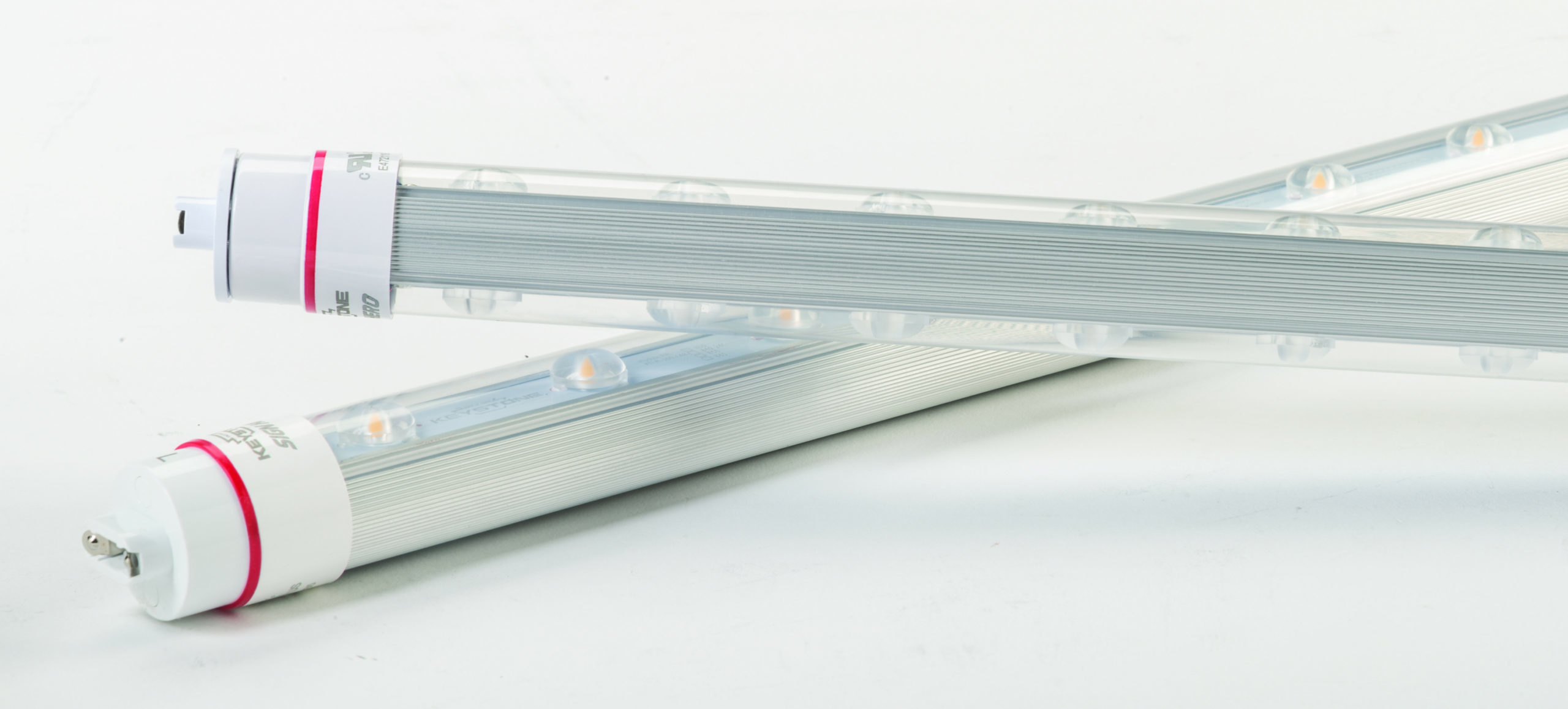

“Here at Keystone Technologies, we are having great success with the Sign Hero product which runs on 120v/277v for cabinet lighting, replacing older, less energy efficient Fluorescent T12HO lamps,” Riley shares. “They have internal drivers so no power supplies to hook up, as well as the long runs will blow you away. Another would be LED HID (High Intensity Discharge Lamps) replacements, mostly used in your large, deep double-sided signs mostly seen 80 plus feet up in the air.”

Yes, there are certainly options. Even when a restaurant owner runs through the simple task of flipping the switch to her custom-branded channel letter sign outside the shop, she has likely run through several critical decisions with a sign maker to reach that point.