Within the constantly changing world of fashion, today’s consumers crave more distinctive offerings than ever before. Traditional printing methods are falling short of meeting these expectations, demanding creative solutions. Digital printing technologies, such as direct-to-garment (DTG) printing, are crucial for adapting to these demands. At our core, we believe in accommodating every customer, even if their demands seem challenging, recognizing the potential for successful relationships to emerge from positive beginnings.

Many customers have come to us after being turned away from other shops, giving us the opportunity to earn their long-term business. Through the integration of digital printing technologies, we’re able to remain flexible with our customers, adapting to evolving trends and consumer preferences. The following examples highlight the diverse applications of our shop’s DTG printer, which we implemented to address the diverse demands of our customers.

Cotton canvas patches

One of the top demands of our customers is always a quick turnaround time. In the age of e-commerce, our customers have been trained by the market to expect what they want to be delivered more quickly than ever. When it comes to decorating beanies, a standard four- to six-week turnaround while you wait for patches to be manufactured overseas can be disappointing to your customer, especially if they are ordering other items from you that can be produced completely in-house more quickly. Most new customers aren’t aware of these types of lead times when they walk in your door and may not understand why their complete order won’t be ready at the same time.

If a customer has a tight deadline for these items, you can lose a portion of the order, or the entire order completely if you aren’t able to meet their deadlines. We came up with the idea of DTG printing cotton canvas to decorate beanies as an alternative to woven or embroidered patches. The large print size of our printer allows us to print full-color gang sheets of patches quickly and affordably. These printed beanies look great, hold up well to wear and tear, and have quickly become a popular option for many of our customers.

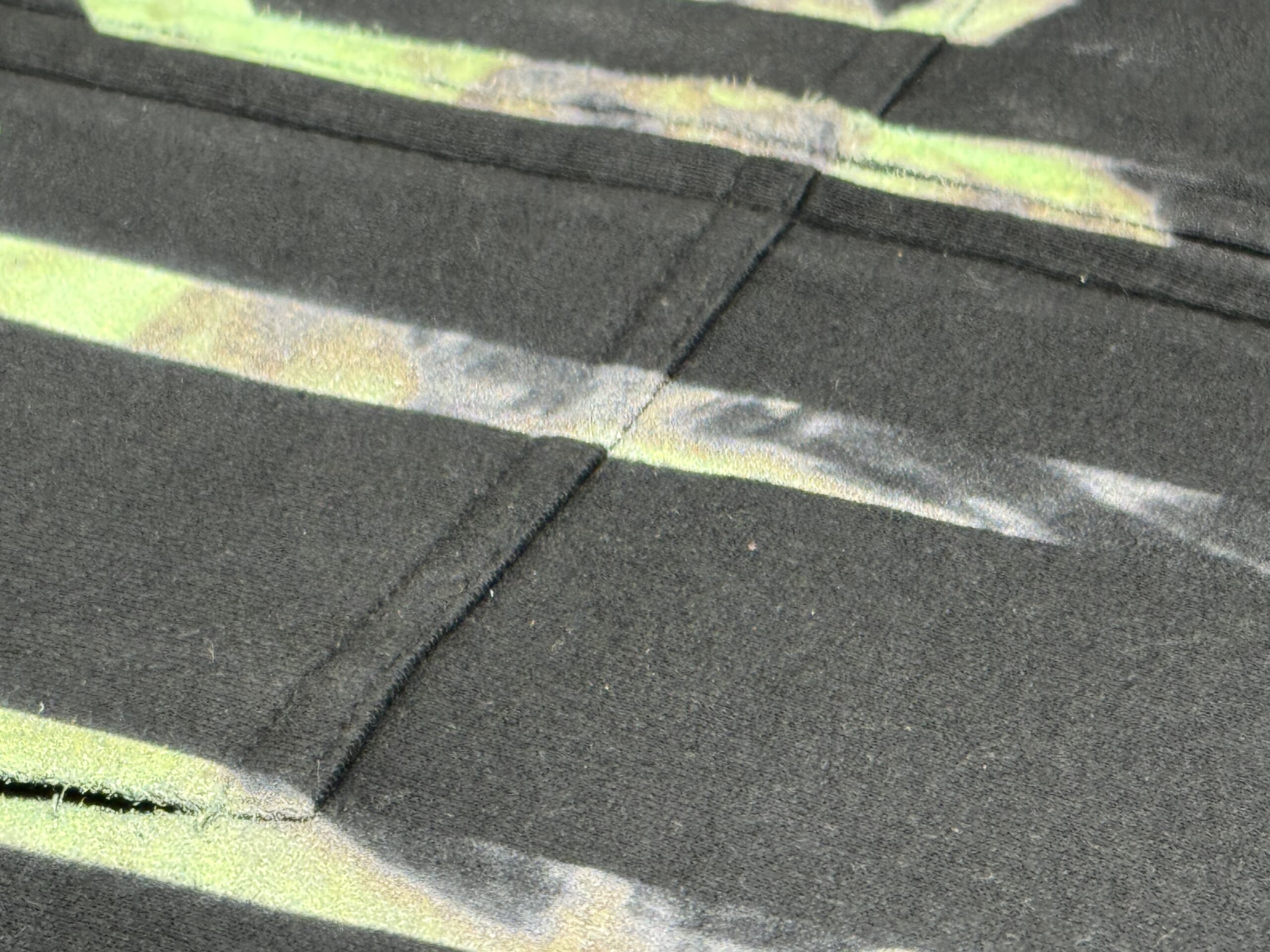

Printing over pockets

For screen printers, a common request from customers ordering hooded sweatshirts is the ability to print over seams, especially on zip-up hoodies. Most shops I’ve spoken to over the years always dread orders like these as they can be a headache to register colors and tend to leave areas of ink buildup or gaps in the print which can look sloppy. The large print size allows prints to not only go over the zipper but the pocket as well, without the worry of a lengthy setup process.

Since ink is sprayed through DTG print heads instead of being pushed through a screen, ink is able to hit every bit of fabric without ink buildup. Using cardboard to help raise the areas of fabric that fall lower than the pockets and seams, we are able to achieve an extremely clean-looking full-color print over seams and pockets.

Decorating outerwear

Another common request from many companies placing apparel orders is the addition of more high-end pieces, such as jackets, to their order. These types of items are more difficult to decorate through traditional methods like screen printing or embroidery. The types of fabrics used can be difficult to screen print, and embroidery can puncture the fabric, making waterproof jackets susceptible to leaks. The DTG printer we use (a Brother GTXpro), not only allows for DTG printing but also has the option to create direct-to-film (DTF) transfers which are an ideal and durable solution for these types of items.

DTF transfers are able to adhere to all types of fabrics at low temperatures, allowing us to decorate on polyester and nylon without worrying about melting or puncturing the garment. The ability to create DTF transfers quickly in-house allows us to easily offer these more expensive items for our customers and are a great upsell for companies ordering apparel for their staff.

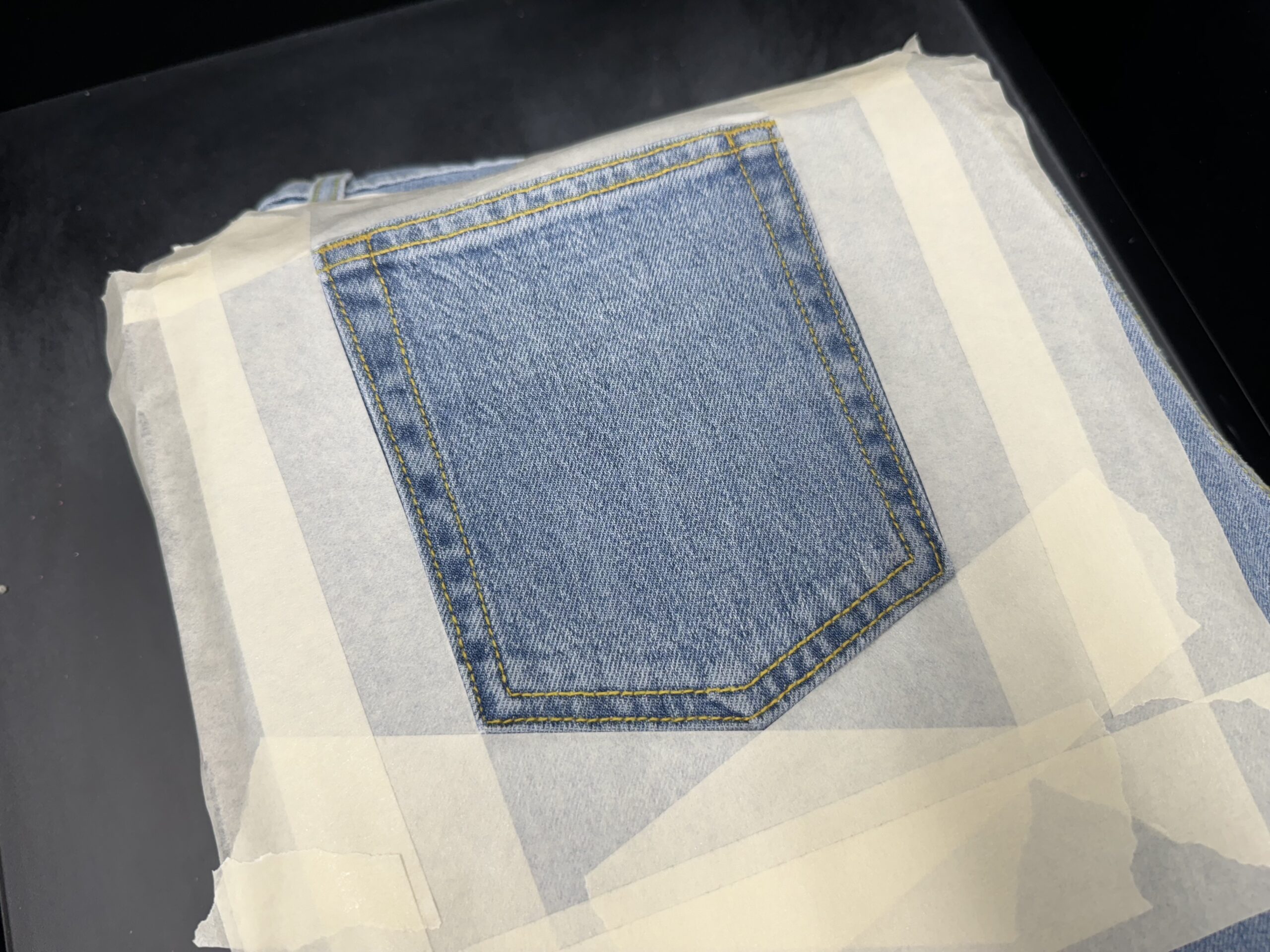

Decorating denim

We were recently approached by a customer with a request to print on the pockets of denim jeans. This was a first for us, but we were up for the challenge. The photorealistic detail of the artwork and placement would be difficult with screen printing, so we opted to try and print DTG instead. We’re able to print on most types of cotton allowing us to print full-color images directly onto denim. After some careful and creative planning, we were able to tape off the edges of the pockets and print the artwork covering the pockets completely.

From the expedited production of patches for beanies to the seamless decoration over pockets and seams on hoodies, the versatility of digital printing has transformed the way we approach custom apparel decoration. We stand firm in our commitment to providing exceptional solutions to our customers, no matter how challenging their demands may seem. By embracing digital printing technologies like DTG, we’ve not only met, but exceeded expectations, earning the trust and long-term business of many clients who have sought us out after facing roadblocks elsewhere. In the fashion market, digital printing isn’t just a phase — it’s a pivotal driver for expanding our business.