TKM Print Solutions, located in Uniontown, Ohio, is the perfect combination of high-tech and

Midwest charm, mixed in with the work ethic and ingenuity of the nearby Amish communities.

TKM started by offering in-house digital wide-format printing services and custom-branded promotional products. Eventually, the company added the capability to custom fabricate boxes, cases, and displays using acrylic and a large variety of composite substrates in flat stock and roll materials.

Going back to Ohio

I had the opportunity to meet with Luke Messner, president of TKM Print Solutions, at the company’s new 50,000-square-foot location with a current workforce of about 20 people. We discussed history, business trends, equipment, and the importance of fulfillment and logistics.

“TKM was founded in 2008, by my father, Thomas K. Messner Sr. At that time, he had over three decades of experience as a print salesman/broker. He became frustrated with some of the wide-format services that were coming to market and the development of new technologies that his existing suppliers were neglecting,” says Messner. “He saw an opportunity that he could embellish with superior customer service and the quality he was accustomed to and finally have in-house production control. We started first and second generation at the same time. The company looks a lot different today; even our focus has radically changed.”

TKM initially came to market with large-format printing and digital die cutting. The competition then was traditional screen printers. It was not too long before the Messners realized their initial niche was low volume and quick time frames that screen printers could not meet.

Eventually some of those screen printers became customers to handle those more custom requests from their clients. “Screen printers and commercial sheet-fed printers at that time were a big part of the market share,” says Messner. “We were also supplying to print brokers and to other smaller printers who didn’t have the technology that we had. We started with an Acuity HD 2504 flatbed printer and could print three 4×8 sheets an hour. Cutting edge at the time and yet so hard to believe looking back we produced so much.”

From senior to junior

Thomas Messner Sr. had been a very successful print broker in the Cleveland/Akron markets for decades. He was well known and respected for his uncanny eye for color and the ability to find and coordinate projects both large and small.

Key to his success was his ability to facilitate the successful fulfillment of his projects. He learned early on it was one thing to make a product, but a completely different discipline to provide the ultimate back-end logistics to bulk deliver to his client or package and ship to multiple locations of those clients’ customers. Messner Sr.’s vision of successfully combining an emerging technology while providing his clients with the turnkey solutions they had relied upon were the cornerstones of TKM Print Solutions beginning.

That philosophy continues. “My dad’s got over 50 years in printing experience. He has seen the evolution of printing over the last 50 years, and it has been dramatic. But the evolution of printing over the last ten years has trumped most of that. For us, when we started, we realized we weren’t going to win on speed; we needed to win on quality. We also needed to win on customer service,” explains Messner. “For us at that time, printing three sheets an hour meant that sometimes we needed to run the press 24 hours a day, seven days a week for a month straight. There were times early in the start of our business when we didn’t have nearly as many employees; it was me and a few other people. We would work all night. The press took long enough to run that we could set up a little cot and sleep by the cutter if we needed to or sleep by the press and set a timer for every 20 minutes. It seems crazy, but that kind of work ethic is largely what drove us and continues to fuel our growth.”

Back to the future

Fast forward to 2023, and you will find the footprint, equipment, team size and, of course, revenues have increased dramatically since its start. From surviving the Great Recession during the company’s opening year to getting through the recent pandemic, TKM persevered and grew.

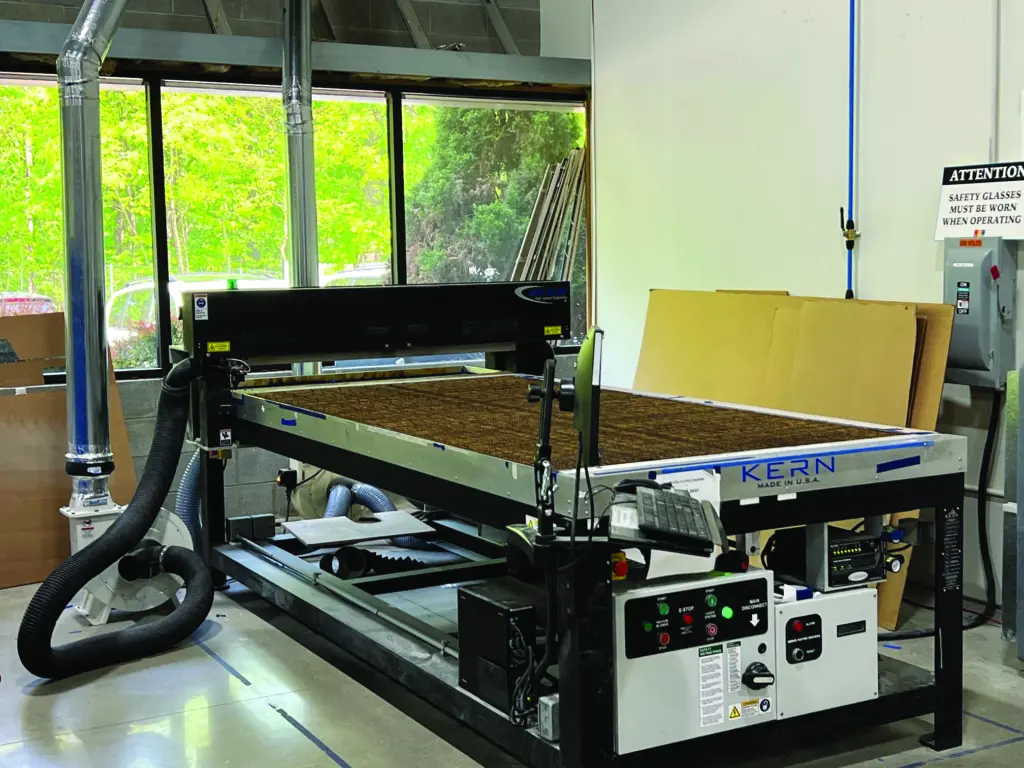

Today, you will find an expansive list of investments that added growth. The initial Acuity machines have been replaced by a swissQprint Nyala large format roll and flatbed printer, an EFI VUTEk H5 that prints 30 full sheets an hour (quadrupling the speed of the old Acuity machines), two D3 automated Zund Cutters, a Zund G3 cutter/router, a 4×8 Kern laser and a liquid UV material coater.

The addition of a laser complements the Zund D3 cutters and gives a quick, flame-polished finish to acrylic pieces. Acquiring the assets of a local acrylic fabricator provided the equipment and knowledge to grow beyond traditional paper and plastic substrates and the ability to create unique components for point-of-purchase displays and other applications.

The company’s focus currently is on providing retail graphics to three types of customers: Corporate and product distributors that sell product at retail stores, brick-and-mortar retail stores where those products are sold, and point-of-purchase display companies.

With more than $1 million in recent investments in equipment and technology, the key to ongoing success is the people.

You can’t print core values

“Perhaps our greatest growth has come from growing and maintaining our quality team members. Much of our team has been with us for years and our extended family still steps in and helps. Printing has become more and more about people and process,” Messner says. “Our core purpose for being in business is to Make Life Better for our clients, our employees, their families, our community, vendors, and shareholders. We live by our TKM Core Values of On It. Own It., Push Hard Every Day, and Figure It Out.”

Further defining this Messner adds, “TKM aims to make life better for customers by building the best production process we can and working hard every day to help our customers achieve their timelines and goals. TKM aims to make life better for employees by cultivating a positive workplace environment, communicating heavily about our vision and goals and how we’re measuring up, and providing good benefits, good pay, and a monthly cash bonus profit-sharing plan tied to the company’s financial performance. “On it. Own it,” ultimately boils down to trust and accountability. We realize we must earn that trust with our customers every day on every job. Committing to extreme accountability can take different forms.”

“One time we couldn’t finish production by the UPS and FedEx shipping deadlines. Our customer was scheduled for a major meeting with one of their customers the next day. We put one of our people on a plane, flew the finished goods to the customer early the next morning, and hand-delivered the job by taxi. Usually, though, taking accountability for our work involves more mundane tasks like checking our work, solving problems, and working out any problems the customers might have. It can also mean tracking how we’re doing from a quality perspective.”

“One major initiative we’re developing is a quality score that can be reported for any customer showing how many jobs, parts, and individual pieces we’ve shipped to them compared to the number of issues the customer has reported. We’re excited about this new tool because it gives our team a concrete way to measure how we’re doing and shows where we can improve.”

Besides people, TKM has a unique and successful strategy when it comes to creating win-win relationships with vendors and maintaining inventory. The company views vendors as part of its extended family.

“We view vendors as a pivotal part of our team and monumental to our success. They take care of us, and we make sure we take care of them. We have developed unique partnerships with some of our substrate partners where we inventory products for them and pay as we go. This enables us to quickly move forward on virtually any type of product, large or small, without depending on a supply chain that can become unreliable,” explains Messner.

The ability to have on-site access to large amounts of sheet stock definitely gives them an advantage in many large time-sensitive projects, thanks to a vendor relationship.

Circling back … and forward

TKM’s central location puts it within 500 miles of most of the markets it caters to. Access to freeways, tollways, railways, and even airports offers a competitive advantage for product costs and for shipping fees for its clients.

“We realized we needed to focus on the things that we wanted people to think of when they thought of TKM: high perceived value, great customer service, exceptional sharing of information, rapid responses to emails, and RFQs. We have an extreme desire to improve our processes every single day. We believe there’s no idea that’s too crazy if it fits within the focus of what we’re trying to do here at TKM,” explains Messner. “We’d like to double in size in the next five years, and we’d like to double that growth again in the next 10 years. We believe we can get there under our context of Make Life Better. We don’t want to do that by doing two to three times the volume of work that we’re doing now and ask everybody to work two to three times harder. So, everything that we do has to be focused on making life better by transitioning into our new facility and continuing to invest in technology, processes, and people to achieve those goals.”

TKM Print Solutions is a prime example of the growing trend of businesses in our industry that don’t look at simply selling as many widgets as possible at the cheapest price. Instead, they offer a turnkey solution to their client needs, which is the face-to-face customer service at the front, quality workmanship, and a dependable fulfillment system with follow-up.

Messner sums it up best with: “Our clients don’t buy printing from us; they trust us to provide the solutions and services to meet their needs.”