Sign shops, trophy shops and engraving companies typically have a CO2 laser engraver that allows them to cut and engrave anything from acrylic to wood, glass, ceramic, paper, cardboard and even rubber.

“The fact that the laser machine can work with such a large variety of materials and processes … makes it the most valuable piece of equipment in any type of fabrication market,” says Jen Anthony, owner and manager of Engrave-Tech & Graphics, a manufacturing company based in San Antonio, Texas, with its main line in signage. “There’s a number of ready-on-the-market things you can make with a laser or you can create your own.”

An Assortment of Products

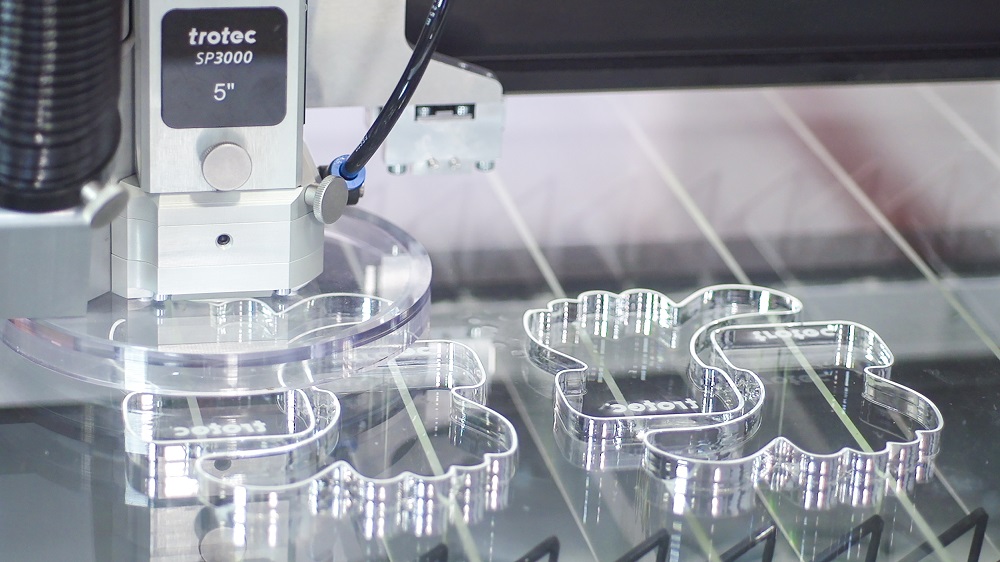

The laser engraver allows companies to make an assortment of products, such as tags, identity plates and labels, and enter a wide variety of markets including signage, display, awards and recognition, rubber stamp and personalized products. These companies often use acrylic, which is readily available and easy to laser, but there are other options of materials that have many benefits.

“Lasers are incredibly versatile machines for both cutting and marking a vast number of substrates. While acrylics are by far our favorites, lasers are exceptional for marking wood, cork, leather, aluminum, brick, glass and many others,” says Bobbi Payne, technical services advisor for Rowmark LLC, a sign plastic manufacturer in Findlay, Ohio.

Working with acrylic requires fewer steps than the other materials, presenting one of many advantages, says Dave Stevens, industrial applications manager for Trotec Laser Inc., a provider of high-speed laser equipment based in a Plymouth, Michigan.

“Acrylic can be produced with a clean flame and polished-cut directly from the laser system, requiring no post-processing like most other methods of cutting,” Stevens says. “The fast laser engraving, marking and unmatched laser cutting ability, combined with the versatility, convenience and affordability, are just a few of the main draws of acrylic.”

Unlike most other materials, acrylic allows for engraving at depth with cuts into the material and for marking, providing a contrast without depth, Stevens says. Acrylic also can support glazing, where the laser produces a window or opaque clear effect on frosted acrylic, he says.

“It doesn’t take much to leave a mark on (acrylic), and the mark it leaves is a nice, frosted contrast, usually to the clear acrylic or even the coated acrylic,” says Sara Thompson, fabrication supervisor at JDS Industries Inc., a wholesaler of personalization and sign supplies in Sioux Falls, South Dakota.

Acrylic’s Many Advantages

Acrylic is a convenient and affordable alternative to glass, another material used in many markets, but unlike with glass, the laser can easily cut through acrylic, Stevens says.

“It is also a popular material to laser process due to its adaptability,” Stevens says. “We find that customers are often drawn to its wide variety of color choices, textures and finish combinations. … Its high levels of clarity, lightweight nature and durability make it a desirable material.”

Acrylic is also easy to clean, simply needing to be wiped with a dry cloth, Thompson says.

“It can look like high-end pieces for a lower cost compared to crystal,” Thompson says. “With so many shapes offered, based and non-based, colored, coated and other accent additions to acrylic and overall user friendliness of the product, it’s easy to see why it’s so popular. … The color accents with all the bevel options help add that nice pop of color if that’s what you’re looking for.”

Acrylic has a few drawbacks, such as flare-ups occurring when cutting thicker acrylic and susceptibility to scratches, Stevens says.

“This might relate to machine exhaust and wattage, so it is important to adjust settings accordingly. With proper training and material understanding, however, this can easily be handled,” Stevens says.

If too much heat is applied no matter the thickness, acrylic can bubble and burn on the edges, Anthony says.

“When you’re cutting acrylic, you have to learn the speed and power settings on your laser to ensure it doesn’t overheat,” Anthony says.

Extruded vs. Cast Acrylic

Laserable acrylic comes in two forms, extruded or cast, Anthony says. Extruded is pushed through a form that makes it into the shape of the desired end product, while cast is made from a liquid acrylic that is poured into a mold and formed into sheets.

“Both are readily available on the market, but most people don’t know to ask for the difference,” Anthony says.

Extruded acrylic comes in many colors, finishes and gauges and is well suited for signage, identification and awards and recognition applications, Payne says.

“When you blend the different finishes with other laserable substrates such as wood, you can achieve a memorable, unique award that any recipient would be proud to display,” Payne says.

Cast acrylic presents a better option for laser engraving and etching, while extruded acrylic produces better results when vector cut on a laser engraver, Anthony says, adding that it produces clean edges for things like letters and shapes. It is less expensive, more consistent in thickness and softer with a lower melting point that makes it easier to cut, she says, adding that it also is easier to polish.

Cast acrylic is used for processes like rastering, where the material is etched out, leaving a fine dusted appearance to look like etched glass, Anthony says.

For high-end products, Engrave-Tech & Graphics prefers using acrylics, especially combined with other materials, Anthony says.

“To create high-end signage, you typically mix multiple materials,” Anthony says, adding that lasers can be used for custom cuts and shapes or to add logos or design elements to the face of the sign. “The customized or specialized look is high-end.”

Several other substrates can be used for high-end engraving, such as thicker, exotic colored glass, polished metal, stainless steel, exotic hardwoods, burl wood, quality glass or crystal, and dark high-end and semi-precious stones, Stevens says.

“With the right framework, any substrate can be used to generate a unique, excellent product,” Stevens says. “Laser cut and engraved natural materials tend to produce a much higher perceived value … especially when two or more are combined together to create modern shapes and designs.”

Glass, Crystal and Ceramic

Three other materials that can be engraved on a laser engraver include glass, crystal and ceramic, though they are too dense for the laser beams to make a full cut and are better for etching, Anthony says, adding that the result is similar to etching acrylic with a frosted surface. The materials are used in products like award plaques, etched glassware, done with a rotary attachment, and engraved ceramic tiles, she says.

Glass is not as easily scratched as plastic, but it is not as forgiving, can shatter easily and is prone to chips, bubbles and other imperfections, plus does not result in as precise of detailing, Thompson says.

“It can look more chipped or flaky and not just a coating reaction like cast acrylic where it leaves a nice frosted look,” Thompson says. “The look and weight of glass gives people that feeling of it being high-end or super expensive.”

Laserable rubber, made out of synthetic silicone and used for things like rubber stamps and stencils, can also be engraved and cut on a laser engraver.

“Make sure the material is laserable, so you don’t release toxic fumes into the environment,” Anthony says.

Leather and Stone

Another material that can be marked and cut with a laser engraver is leather, which is popular in the personalization market, for items like key chains, coasters and bag and purse tags.

Stone, such as slate, granite, marble and quartz, can be engraved using a laser to create monuments, custom pavers, coasters and gifts. Lasers also can be used to cut cardboard, plywood and balsawood to make prototypes and architectural and other types of models. It can cut Mylar, a type of polyester film, and oil board, cardboard that has been coated, to create stencils. And it can cut paper for stationary, invitations and latticework and laser etch wood for gifts and personalized signs.

Using a laser engraver to cut the different types of materials doesn’t present too many drawbacks, Anthony says. The key instead is to make sure to identify the right speed and power settings for the material and working environment, such as it being hot, cold or humid, she says.

“It’s a little bit of a trial-and-error process to find the best setting for each of these types of materials,” Anthony says.

Materials to Avoid

Some materials cannot be cut with a CO2 laser engraver, such as polycarbonate and polyvinyl chloride, or PVC, because of the fact they release toxic fumes, and metal because it is reflective, Anthony says.

Coated metal, such as black brassed steel or anodized aluminum, however can be engraved by removing the coating from the metal to make things like plaques, trophy plates and signs. Another option is two-ply engraving plastic, where the cap is removed with the laser to reveal the core. There are also products on the market that can be applied to stainless steel for laser engraving to create a permanent engraved marking.

“Finding the right settings for your specific laser is important with all materials and can make all the difference in your end results and making a plain piece into a piece of art,” Thompson says.