New Product Alert: SwissJet Inks For Sublimation

In order to get the absolute best results with the SwissJet inks, you'll need to remove the old ink from your system before converting to the new ink.

About this Sponsored Content

Johnson Plastics Plus, headquartered in Burnsville, Minnesota, has been a leading supplier to the engraving and sign making industry since 1970. Our Johnson Plastics Plus commitment to serving the needs of the engraving, sublimation and sign making customers remains our primary focus. Visit www.jpplus.com for more information.

We’ve got some good news and we’ve got some bad news.

The SubliM and SubliM Intense sublimation ink product lines for large-format printing have been discontinued as of fall 2019. That’s the bad news…

…but the GOOD NEWS is that the Johnson Plastics Plus product team has found a replacement ink, SwissJet, that performs better, lasts longer, and costs less that the SubliM inks.

WHY IS SWISSJET THE BEST OPTION FOR ME?

SwissJet inks were developed by the same team that developed the SubliM inks. SwissJet takes sublimation inks to a whole new level by improving the ink carrier while maintaining outstanding color reproduction. The improved carrier means extending the shelf life of the ink and extending the life of your print heads. Through our testing, we were also able to verify that you should see little to no color shift over what you were getting with the SubliM inks.

And here’s the best part: SwissJet inks are only $99 per liter, a savings of $50 over the SubliM inks!

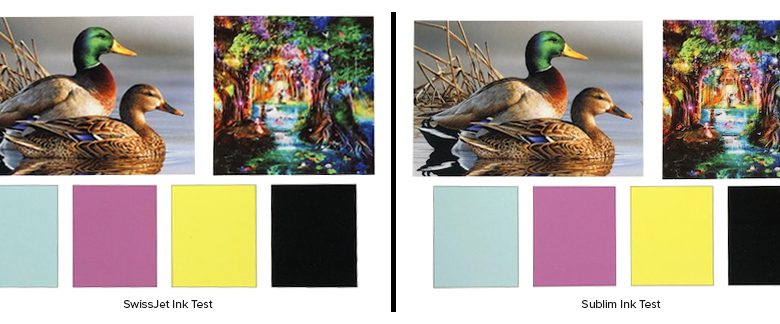

As you can see from the tests above, there is no discernible difference between printing with the SubliM and SwissJet inks. Both tests were done on hard substrates.

CONVERTING YOUR PRINTER TO SWISSJET INKS

In order to get the absolute best results with the SwissJet inks, you’ll need to remove the old ink from your system before converting to the new ink. You can do that one of two ways. We highly recommend running a cleaning solution through your printer then installing the new ink. This ensures there’s no residual ink left in the system.

The second option simply drains the old ink from the system before converting to the new ink. We have simple, step-by-step instructions no matter which method you choose:

Generic instructions for converting ink on your sublimation printer.

Needed supplies:

- Option 1: Recommended for best results

- New ink carts, one per slot with funnel

- Cleaning carts, one per slot

- Cleaning solution, minimum 1 liter

- New ink

- Option 2:

- New ink carts, one per slot with funnel

- New ink

Option 1:

- Empty then reinstall the waste tank.

- Flush remaining old ink from the system.

- Process varies by printer

- Run cleaning solution through the ink delivery system.

- Empty then reinstall the waste tank.

- Install the new ink carts.

- Fill with the new ink using the provided funnels.

- Be sure to match the color channels correctly.

- Fill to about 2/3rds full.

- Charge the new ink into the printer.

- Run a nozzle check.

- If the nozzle check comes out good, then you can proceed to updating your configurations for the new ink within your RIP Software (if required).

- If there are missing nozzles, run a cleaning cycle and then another nozzle check; repeat until the nozzle check is good.

- Empty the waste tank and reinstall.

Option 2:

- Empty then reinstall the waste tank.

- Flush remaining old ink from the system

- Process varies by printer

- Empty then reinstall the waste tank.

- Install the new ink carts.

- Fill with the new ink using the provided funnels.

- Be sure to match the color channels correctly.

- Fill to about 2/3rds full.

- Charge the new ink into the printer.

- Run a nozzle check.

- If the nozzle check comes out good, then you can proceed to updating your configurations for the new ink within your RIP Software (if required).

- If there are missing nozzles, run a cleaning cycle and then another nozzle check; repeat until the nozzle check is good.

- Empty then reinstall the waste tank.

If you would like assistance with the conversion, we can help walk you through it over the phone. Please call 800-869-7800 and ask to speak with Jim Hagen.

New ink carts are necessary as using the old carts could contaminate the new ink and cause issues with your colors or worst-case scenario cause a print head failure. This is usually due to ink that has settled out. Ink in the lines when using option 2 will not cause an issue.

The ink delivery system is not a warranty part. We have found these instructions to be sufficient in retaining function of the ink delivery system but cannot guarantee that your ink system will have the same outcome. Outcomes may vary based on print head life cycle and routine maintenance done prior to the conversation.

We have found color output to be very similar to that of the original Sublim ink but you may need new color profiles and configurations for your printer.

For your convenience, below is a cross reference chart showing the old SubliM item number and the new SwissJet item number.

| SubliM Item Number | SwissJet Item Number | Description |

| LFEB | SJS-K | 1 Liter Black Dye-Sublimation Ink |

| LFEC | SJS-C | 1 Liter Cyan Dye-Sublimation Ink |

| LFEFP | SJS-FLP | 1 Liter Fluorescent Pink Dye- Sublimation Ink |

| LFEFY | SJS-FLY | 1 Liter Fluorescent Yellow Dye- Sublimation Ink |

| LFELB | SJS-LTK | 1 Liter Light Black Dye-Sublimation Ink |

| LFELLB | SJS-LTLTK | 1 Liter Light Light Black Dye- Sublimation Ink |

| LFELM | SJS-LM | 1 Liter Light Magenta Dye-Sublimation Ink |

| LFEM | SJS-M | 1 Liter Magenta Dye-Sublimation Ink |

| LFEY | SJS-Y | 1 Liter Yellow Dye-Sublimation Ink |

| LFELC | SJS-LC | 1 Liter Light Cyan Dye-Sublimation Ink |

We know you’ll love the performance and cost savings on the SwissJet inks, and we’re happy to be able to offer them to you. If you have any questions at all while you switch to the SwissJet inks, please do not hesitate to call us at 800-867-7800 or email service@jpplus.com.