The multifamily building boom has been going on for years in the U.S. and promises to continue. As a graphics professional, I’m sure you’ve noticed and often wondered who is doing these amazing signs and graphics for new apartments and the large number of rebranded properties, and how they’re getting it done. Let’s take an in-depth look at what is involved in these exterior and interior signage programs.

Modern marvels

A lot has changed over the years with technology, fabricating, and marketing for sign companies. Gone are the days of calling up your local sign shop to paint a wooden sign at the entrance of your apartment and then having your property manager handle all the other facility signage in a hodge-podge manner. In today’s modern world, there are architectural sign firms that specialize in providing turnkey design, manufacturing, and installation of everything related to signage and graphics.

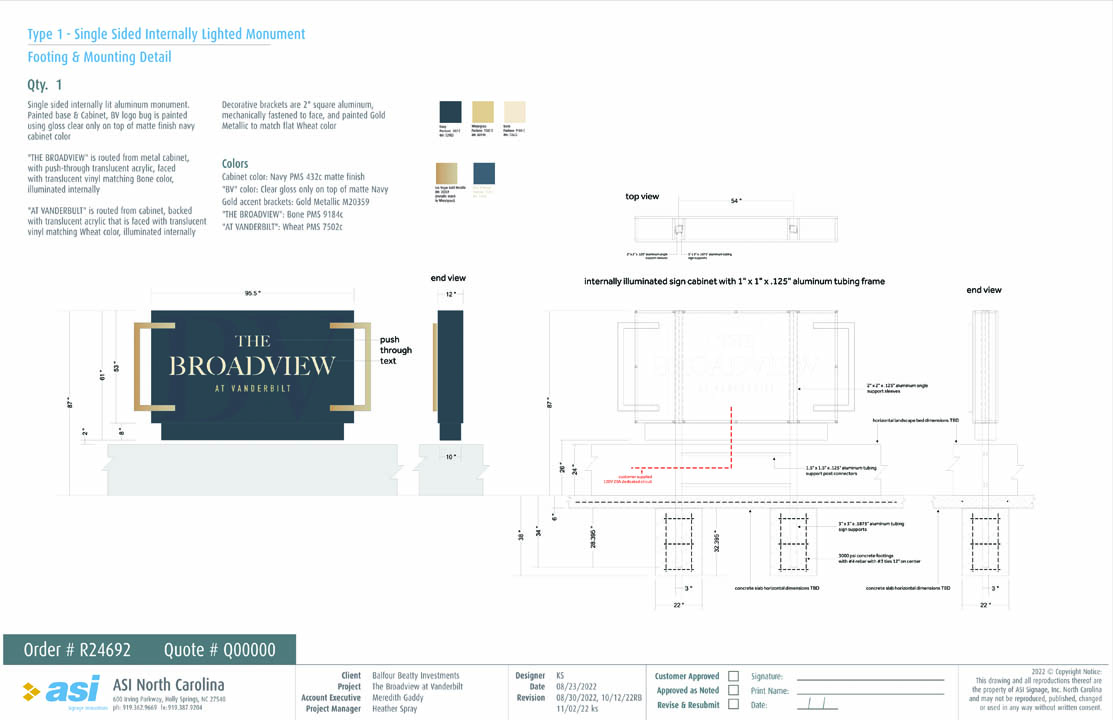

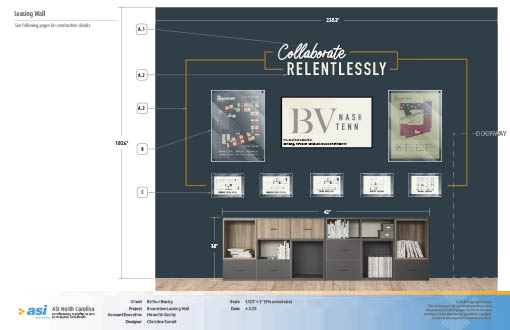

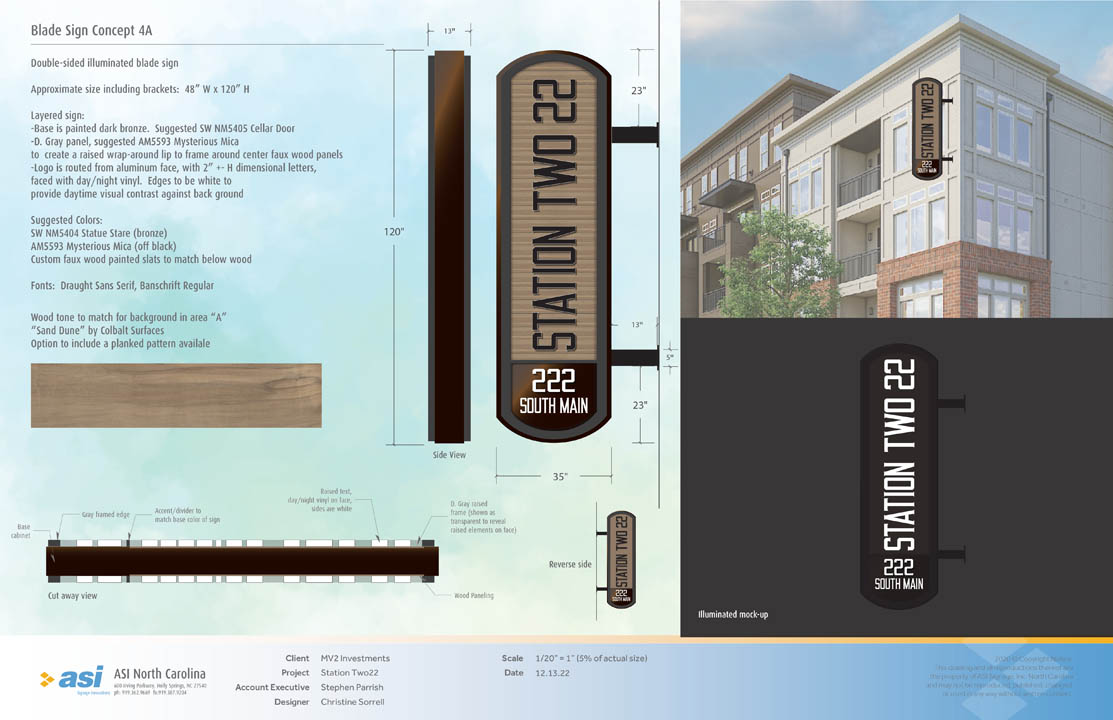

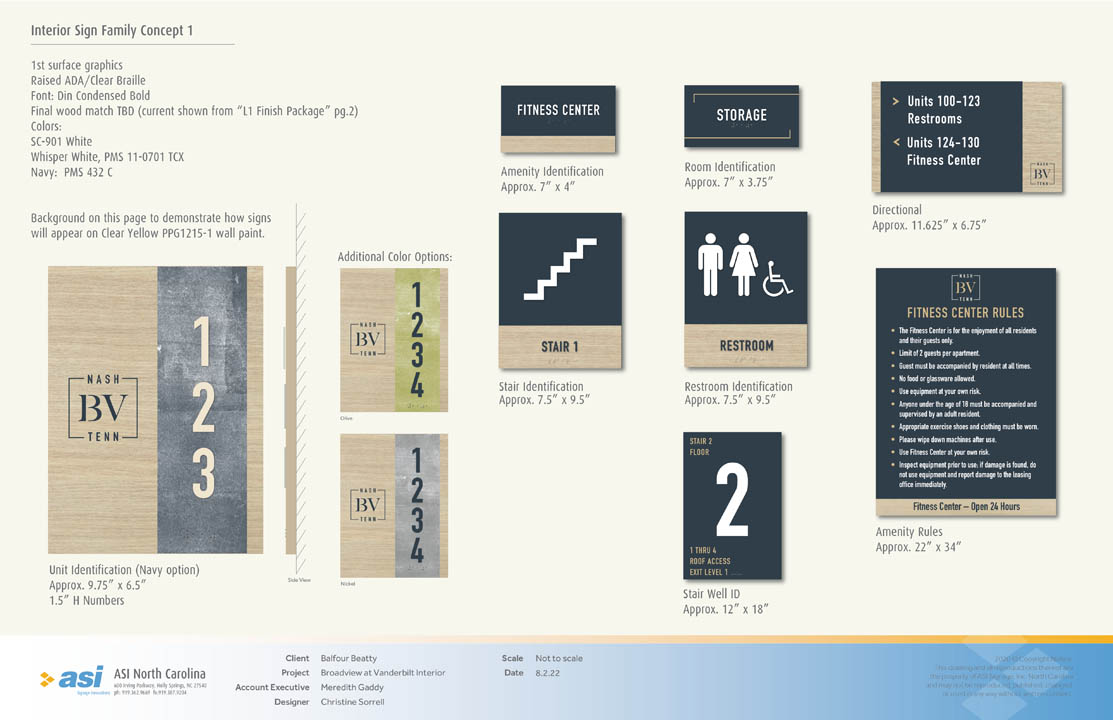

From an internally illuminated blade sign on a building to the smaller, strictly enforced code signs found inside, and everything in between. Today’s signmakers create a consistent and branded environmental graphics package that features materials and colors that seamlessly blend together taking cues from the architect and interior designer.

Cast of characters

To help with a basic navigation of some of the behind-the-scenes work involved with sign programs of this type, I’ve enlisted the help of George Randall with ASI in North Carolina. Much of ASI’s work is in Charlotte and Raleigh. Both markets are in the top 10 in the country for multi-housing construction. George has been in the signage industry for over 20 years, and the last 10 have been as a project manager for architectural signage projects (referred to as “programs”) for both the multihousing, student housing, and education markets.

“The magic all starts with our business development and design build teams. They take a consultive approach with the owner’s representatives, architect, and interior designers,” Randall said. “They weed through plot surveys, floor plans, and interior design specifications. From there, they pull finishes, architectural features, and any significant corporate art guidelines together for initial design concepts and an overall scope of work that covers all signage and graphics, inside and out.”

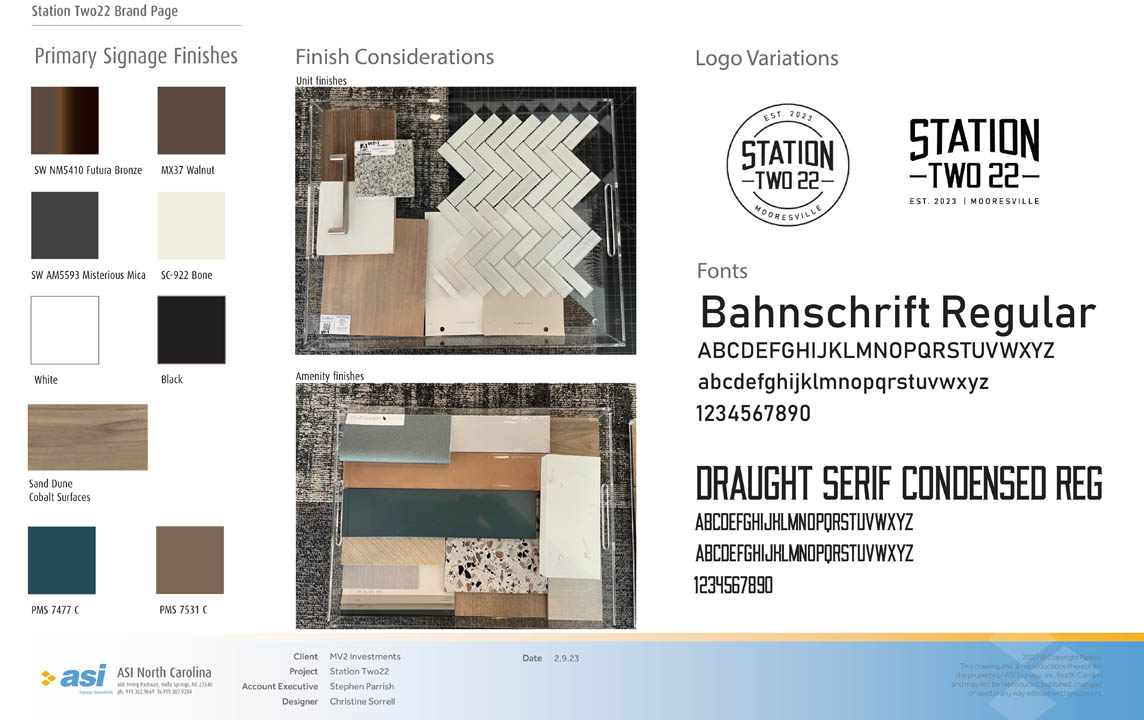

During this process, a designer presents a mood board to the client illustrating how architectural elements, colors, substrates, and any branding elements are to be incorporated.

“A lot of creative work and detailed review of all the project’s signage needs inside and out is used to create concept sign types. Ideally, the goal is to keep colors, substrates, fonts, and other graphic elements cohesive and consistent to develop a unique brand for the property. We are then able to create a comprehensive package that includes interior and exterior main identification signage, wayfinding, and individual room signs. A detailed message schedule and location plan is carefully prepared. These serve as the projects go-to documentation for manufacturing and installation of the job,” Randall said.

How it’s made

Signage pros put forth a lot of effort behind the scenes during this process to determine exterior signage limitations as well as requirements for signs to be permitted within local and state codes. For interior signs, additional Americans with Disabilities Act (ADA) requirements impact the scope of work. Upon final approval of drawings and sign counts, the program is released for production.

“The sales and design group may have started the magic, but it’s up to the project manager to coordinate all the behind-the-scenes grunt work to create specific timelines, run logistics, and coordinate the work among internal manufacturing and any subcontracted outsourced work,” Randall said. “There are multiple elements up in the air at any moment. Permits need to be applied for and secured before those exterior elements are approved for production, and we are often coordinating (and sometimes battling) with other trades to complete their work so we can do our signage and graphic installations.”

Randall continued, “You can’t install wall coverings on wet paint, it needs to outgas first. You can’t install canopy letters if the canopy isn’t up. It’s not as easy as picking a day or two to go out and get the job done. We are at the mercy of weather, issues with other trades not completing on time, or a municipality moving slowly to approve permits or perform certain inspections on time. Many people, sometimes our clients included, are surprised to learn that not having all appropriate code-related signs completed can push back a project’s certificate of occupancy. So being on top of all those balls in the air is extremely challenging.”

Randall said ASI has their own manufacturing facilities and can produce nearly all the product needed for a project.

“We do that as much as we can, but there are a variety of reasons we look to qualified subs to do some things. If a project is hours away, we may want to work with some other graphics companies to assist with manufacturing and installation. Sometimes, it might be about freight costs, our own fabrication capacity, or that it just makes more sense to keep some work local.”

As the buildings and grounds near completion, project management is often involved in completing site visits and surveys to assess progress and conditions. Situations often arise, so it is important to be flexible and have the ability to make changes and modifications ahead of time as often as possible.

Sign programs like this involve many specialty areas of signage and graphics. Experienced fabricators are needed to manufacture the custom architectural signage, knowledgeable craftsman are needed to produce the ADA- and code-compliant signs, and skilled applicators print and cut wall and window graphics.

Designers on these projects have extensive backgrounds in wayfinding and environmental graphics. There is often a technical designer on board that creates production artwork and produces any needed outsourced file work.

“None of this would be possible without the unique project management software that allows myself and the entire team at ASI to view projects in real time. Having that information at my fingertips is vital for a project to move as smoothly as possible. We also use specialty programs, like SignAgent, to help with the overwhelming task of creating easy-to-follow message schedules and location plans that help both with fabrication at the front end and installation at the back end,” Randall said.

Building signage for the future

The hours of design, fabrication, installation, and management can take some time. Conceptual designs and initial takeoffs to formalize an estimate and get approvals easily take five to six weeks. Average production can take six to eight weeks depending on the size and scope of the project. Considering that most projects are completed in stages, you are looking at sign programs that can easily span three to six months from start to finish.

You must admit the final product is much more than signage. Many are examples of functional artwork that create an overall vibe or feel for the property, its own unique brand. It’s no wonder that many of the specialized companies like ASI doing this type of work have a high percentage of repeat business going forward. Special thanks to Christine Sorrell with ASI in Raleigh, North Carolina, for providing drawings and photos and their client MV2 Investments whose project Station Two22 was featured.

If this type of work is appealing and in your shop’s wheelhouse, find out who is doing the sign work. A perfect start is an introduction to explain your capabilities; these companies are always looking for local help with interior installations of simple wall signs, vinyl graphics, and wall coverings. You never know what the future may hold.