Recently, we’ve seen a shift into digital on-demand eCommerce market printing — that is, one-of-a-kind units responding to online purchasing. The pandemic has accelerated this shift.

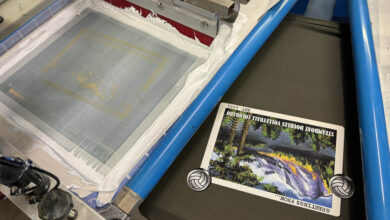

In addition to DTG, hybrid printing is ideal for the new business model that is trending: smaller quantities with a higher degree of personalization.

With hybrid, you can incorporate special effects that you cannot do with DTG alone. These special effects allow you to distinguish your printed designs further and set them apart. Hybrid printing, with its unique advantages, opens the door to new markets and opportunities for those willing to embrace it.

In my conversations with printers about how to market hybrid decorating, there is a new market to be inspired, a blue ocean space.

Here’s an example:

A Mexican restaurant on the beach comes in once a year and buys 300 pieces. Like all businesses, it has slower times, and now, on top of that, the pandemic.

If you have a hybrid setup, recognize this is a unique time for trying new ideas and come up with some variations. One example might be offering a “Pinktober” variation in October, a holiday variation at the end of the year, or for March a St. Patrick’s Day theme.

Instead of selling the same design all year long, they have a fresh design once a quarter to give customers a new reason to engage. For loyal patrons who already have the original design, they get excited about the collectible variations. For new customers, there is a fresh experience. Maybe a variation on the design is created for a special online promotion.

This helps your customer sell more merchandise during a time when food sales are down. Make samples that show what your equipment can do. It starts to open up creative space, and it’s not a huge risk if they’re placing their usual shirt order. You might add only five new pieces of the fresh design. If it sells, you can easily print more.

Template printing in the hybrid space works the same way. Perhaps you offer a circle silhouette on hoodies for customers to fill with digital info and run hoodies for various customers or variations simultaneously.

What’s the talk of the screen printing industry?

The trends predicted pre-COVID were accelerated in the last year and a half. More digital, eCommerce, and smaller run sizes. Being flexible is key; being adaptable to change, evolving, and embracing change is vital as we come out of this. Now more than ever, business owners are more resilient and prepared for shifting markets ahead.

Workflow is also huge right now — creating a frictionless workflow that engages an online platform and delivers efficiently and quickly to your customer base is a huge focus.

Additionally, the DTG landscape is changing dramatically, focusing on newer tech that has higher quality demands and print consistency for retail quality apparel.

What’s happening with supply chains at the moment?

M&R Printing Equipment’s executive VP Peter Walsh shares some insight: “Supply chain management is definitely becoming a greater challenge for garment decorators as we enter the latter stages of the COVID pandemic. Our customers are reporting shortages and delayed shipments of blank garments, and/or the need to ship from multiple sites to complete an order.”

Equipment and supply distributors are also being hit. Walsh adds, “Garment decorating supply distributors are likewise experiencing shortages and delayed shipment of inks and supply products. At M&R, we are seeing shortages and increased prices for critical raw materials to include steel, aluminum, and lumber.”

Learn more: The Argument for Digital Hybrid Print Technology