Let’s Talk Shop: Efficiency = Profitability

Find out how to double your shop's output without adding employees?

Our shop organization, workflow and general systems have evolved over the years and will probably continue to do so. I can remember in the very early years we had no real bookkeeping system in place so we never knew who owed us money. As far as workflow, basically whoever took a job at the counter handled it from start to finish. Talk about inefficient!

Many of our systems came about out of necessity but we’ve also worked hard to put a workflow system in place that maximizes our shop efficiency. Efficiency really does equal profitability. Any process that wastes labor or materials cuts into your profits.

I’ve written articles in the past that focus on certain elements of our system in detail. Be sure to check past articles if you would like more specific information on our workflow system, wrap checklists or specific tips and tricks.

For this article I would like to mention some of the areas that we’ve focused on to create more efficiency. Hopefully this will spark some ideas for you to use in your shop too.

SERVICES

The electrical market in our city is pretty saturated, so although we have an electrical contractor’s license, we pass on these jobs. There are also a large number of apparel shops in our city, so we’ve never jumped into that market.

We focus on signs, wraps, fleet graphics, banners, graphics and engraving. Because we focus our energy on these areas, and don’t spread ourselves too thin, we’re able to produce high-quality signs in the most efficient manner.

Our time and energy is spent on improving our process with these products specifically. We also continue educating ourselves on the best products, processes and tools that pertain specifically to these services.

RESPONSIBILITIES

We run a pretty small shop, as far as number of employees go, but we also run a large volume of work through our shop. Everyone has a general area of responsibility which helps keep us on top of the jobs coming through the shop.

Our production manager oversees the job calendar and makes sure that the jobs in Output are grouped and printed, are moved into production for finishing, and they help with all areas of production. Another person is in charge of all engraving and CNC jobs and coordinating outside installs. We have another person in charge of ordering all materials, overseeing in-house installs and managing large repeat clients. Another person is in charge of prepping in-house vehicle installs and production finish work.

Assigning these areas has come from capitalizing on the strengths of each person. On top of these specific management areas, a handful of us also share customer service responsibilities, pricing, and designing.

A big part of what makes this work for us is cross training. While we may have specific areas of responsibility, we’re also all trained to jump in and help in all areas. Vehicle wraps are my specialty, but I can definitely jump in and help with finish work on the table if needed. If we’re inundated with a large engraving project, any of us can help support the person in charge of engraving to complete the finish work so the job is completely quickly.

Another benefit of cross training is everyone has a better understanding of what is involved in different areas. A person who designs vehicle wraps should also be familiar with the wrap process. By understanding obstacles and how best to install graphics, they’re going to design for efficiency.

PRICING

Over the years we’ve developed pricing sheets for our shop. The pricing is broken down by square footage, vinyl media type and substrates. By having these sheets on every desk and at the front counter, we can all help a customer determine the pricing for their project.

We have pricing broken down for outside services we use as well. Large run screen printed signs, banners and print services, like business cards and brochures, are also pre-figured. We’ll often get the same requests for certain products over and over. By having the pricing pre-figured on these common items, we don’t have to redo the same work repeatedly.

Common sized items, like sets of car magnets, or commonly ordered assembled signs, like a Plasticade a-frame with signs, are also pre-priced. Feather flags, table throws and retractable banner stands are other products that have specific sizing and features that don’t change (other than the artwork) so we’re able to have set pricing for quick quoting.

WORKFLOW

This is a big area for us that we’ve fine-tuned over the years. By having a really good system in place we’ve nearly doubled our monthly sales and production volume with the same number of employees. Our system was built over the years so instead of an all-in-one sign software, we use a couple different programs plus a physical organization system.

I’ll briefly mention some of the areas of our system that keep us on track and efficient. Check our past articles for more specific details.

– Front counter-We use Activity POS software primarily for invoicing/estimating

– Folder system-New jobs are put into numbered bright yellow legal-size envelopes and put under tabs that correspond with where the job is in production-Proofing, Waiting for Approval, Output, CNC/Engraving, Outside, Hold. The rack that holds these are by the design computers. When a job gets to production the folders are moved to that area.

– Toodledo-This is an inexpensive online organizational software that we’ve customized to align to our folder system. From any computer we can check the folder number a job is in and where it is in production. As jobs move through the shop, we update their location in the software.

– Output-When a job is approved and the folder is moved to output, our shop manager organizes the jobs by material type so that all premium vinyl, calendared vinyl and transit media is grouped and printed at one time. This saves time on loading/unloading media, but it also groups the material to maximize efficiency when laminating as well.

– Dry racks-Vinyl wall racks work great. When a roll of media comes off the printer, we hang it up on the rack to dry. It’s a great way to organize a lot of rolls in a small area and keeps the printed rolls from being knocked over or damaged while drying.

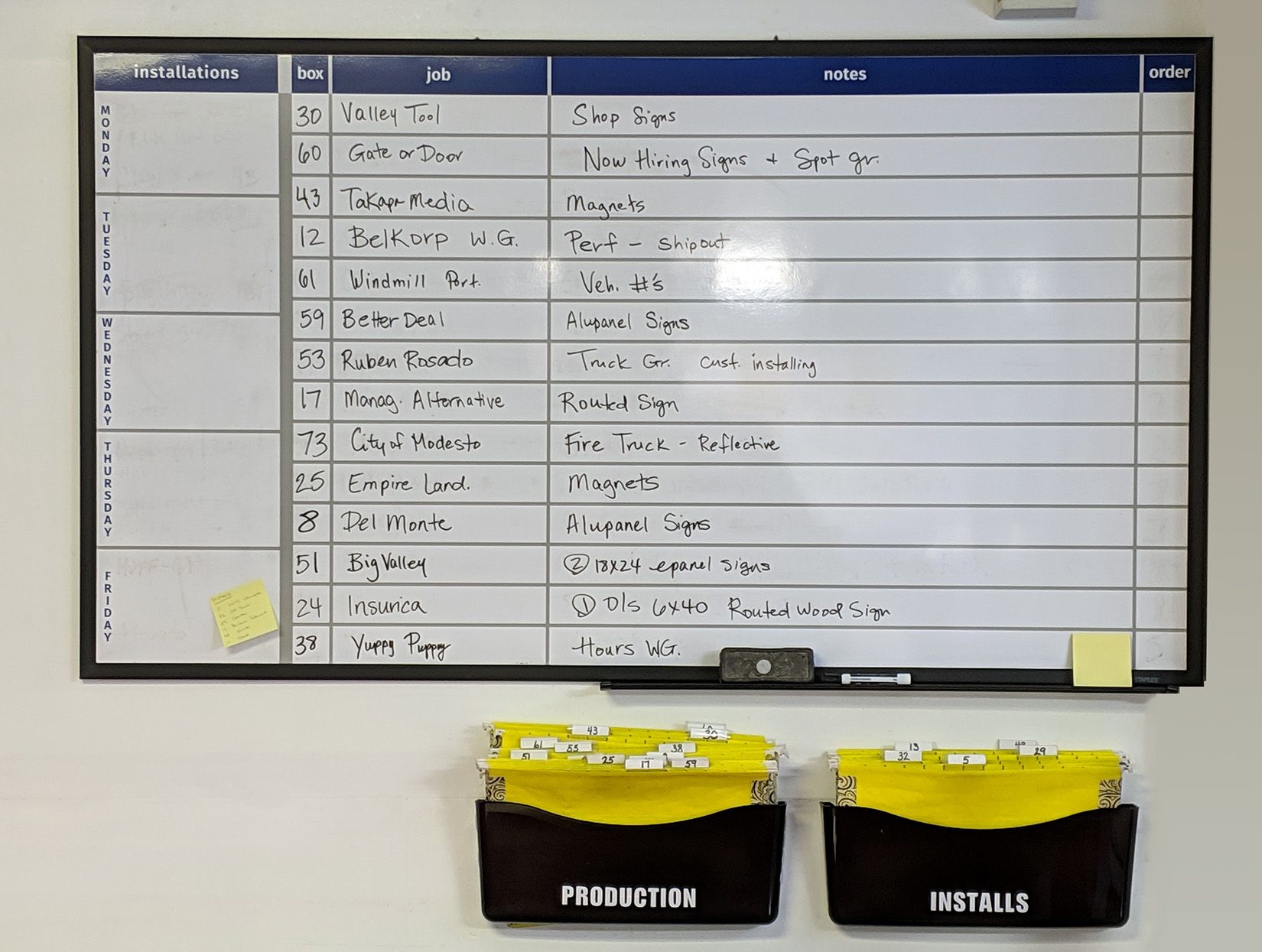

– Production board-We designed a very simple dry erase board for production that lists the jobs that are in production. This means that the job was approved and graphics have been printed or cut. We can note substrates, so they can all be cut at the same time, and jobs can be numbered in order of priority for the day. We have a small section to note the installs for the day as well so they’re ‘at a glance’.

– Production racks-Under the production board we’ve mounted two wall racks. One holds all the job folders that are in production (the job is printed or cut and needs to be finished) and the other rack holds all folders that need installation. This keeps the folders in the production area where they’re easy to find.

– Google Calendar-All of our installs and meetings are put into Google Calendar. This allows us to check the calendar from any computer so that we’re able to quickly check available time slots for adding in installs.

CHECKLISTS

Checklists are a great way to streamline sales and production. We’ve created a checklist specifically for our vehicle wraps. It covers things to look for during the sales process, offers reminders on information we need to gather, records important reference information, notes any existing damage, and offers reminders for the install process.

We also have pre-printed vehicle templates of commonly wrapped vehicles. These are great to grab for noting measurements, existing damage or for sketching out design ideas. We like Art Station vehicle templates; their Wrap Dimensions Guide is also a great resource for quickly quoting commonly wrapped vehicles.

Vehicle care questions are also common after a wrap, so we have a checklist of do’s and don’ts pre-printed out. We printed them on door hangars so we can either hand it to the customer or hang it from the rear-view mirror. A list of washing instructions and other care information is included.

ACCOUNTING

We have an in-house bookkeeper that keeps our accounts organized, so that we do know who owes us money! Two wall racks in a central location allow us to drop finished invoices, meaning the job is completed and either picked up or installed, into either a Paid rack or Billed rack.

The bookkeeper takes it from there. She takes the invoices and files them into the proper areas for tracking sales tax, who still owes us money and cross-referencing deposits and payments.

All of our invoicing is done in triplicate. The white copy goes to the customer for billing or with their payment noted, the pink copy is attached to any work orders or other job information and is filed for future reference and the yellow copy is for accounting. All payments or billing information is noted on the yellow and filed.

BACK UP

A wall of filing cabinets keeps all of our pink invoices, along with any important proofs or other customer paperwork, filed alphabetically. If we’ve done multiple jobs for a customer, then we group their paperwork into a separate folder that is labeled. This makes it easy to grab past paperwork for reference on repeat orders for large accounts.

We also use a backup system for all of our artwork. We have a ‘Working’ folder system for recent projects. After a few months all of these files are backed up and the files are added to Cathy Catalog, a system that organizes jobs by folder. We can quickly search by customer name or key words and the cataloging system will list the results for easy reference.

SMALL THINGS

Efficiency comes in small ways too. Pre-made stamps at the front counter are used for tracking calls on completed jobs and for stamping the date for billed invoices. Work order pads not only look professional, but they’re also always ready to go on a clipboard to be grabbed for note taking at the front counter.

Supplier resources, color charts and material samples are kept at the front counter for easy review with the customer. Photos of jobs on the wall and on our website, that is always open on the front counter computer, make it easy to point out sample jobs and to steer the customer in the right direction.

Stocked installation kits for outside installs and stocked tool chests for in-house installs make sure that we’re prepared for all installations. A dedicated Order Form makes it easy for anyone to note an item we’re running low on so that the person in charge of ordering can efficiently order items to meet minimum orders.